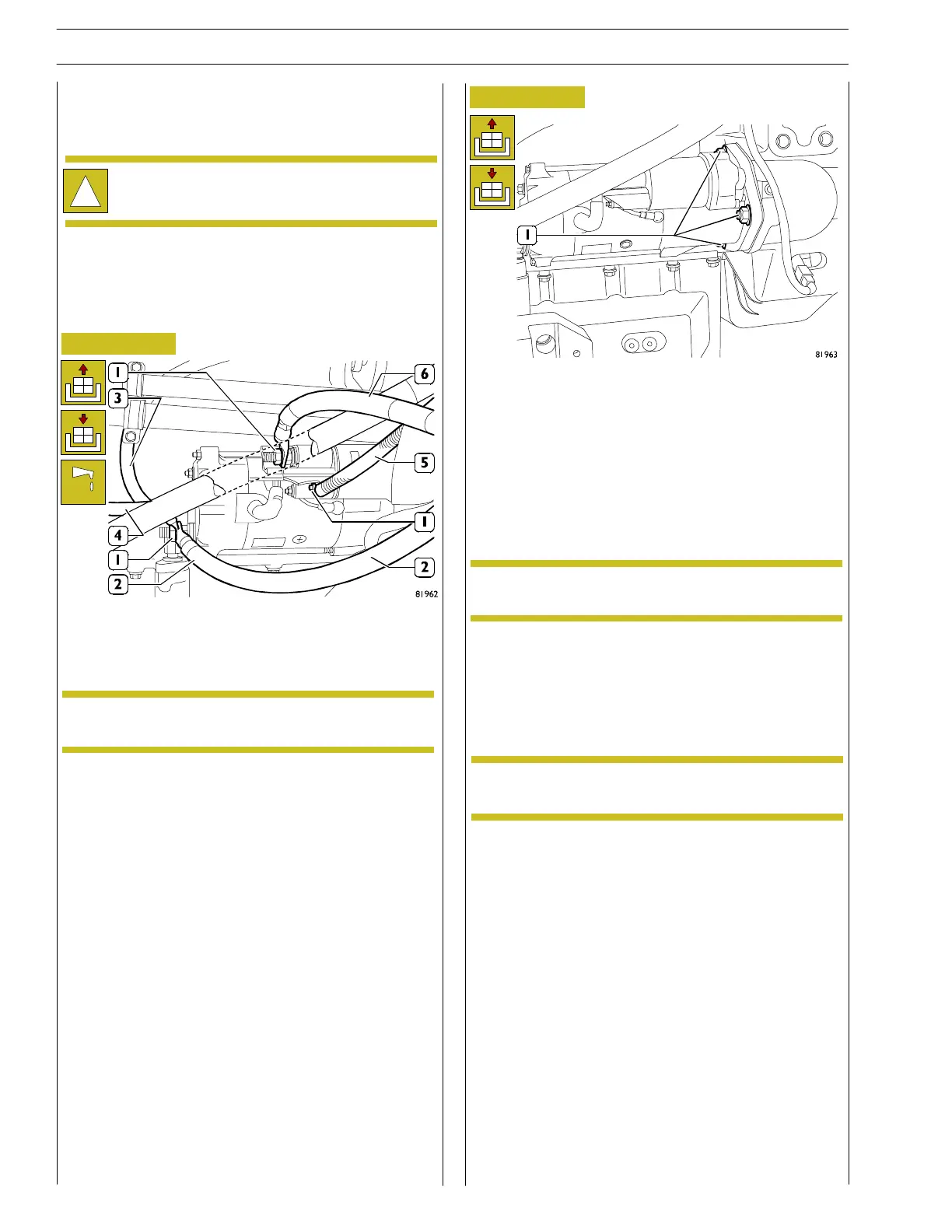

- Restore the electrical connections.

Tightening torque should be as follow:

Terminal 30: 20 ÷ 30 Nm

Terminal G: 20 ÷ 30 Nm

Terminal 50: 2 ÷ 3Nm

Apply a light layer of Vaseline onto the terminals

to protect them from rusting.

- Check the engine starting.

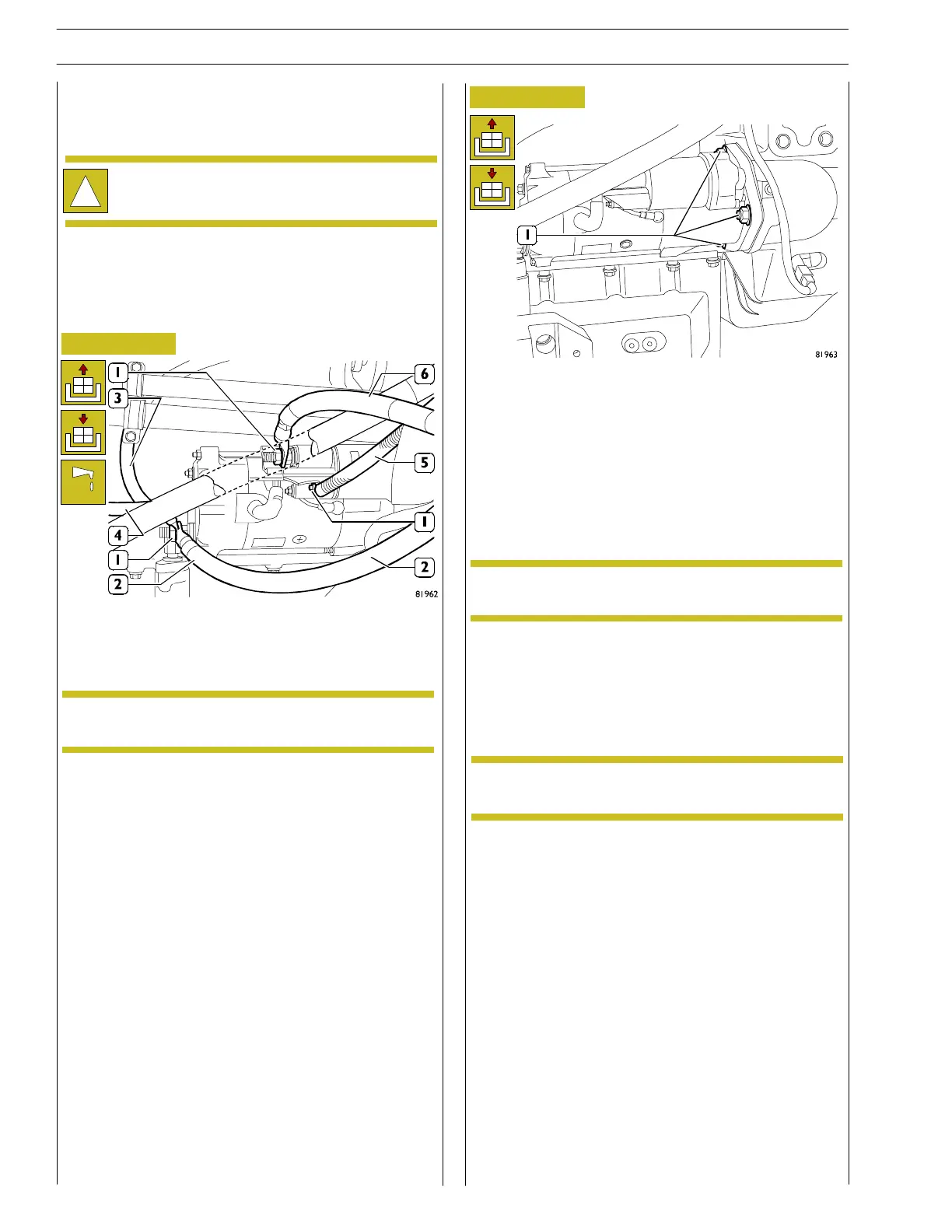

Figure 35

The starter motor is located on the left-hand side of the

flywheel housing in an area fairly easy to access from the

bottom. Its disassembly requires no special tools an d is not

particularly difficu lt. Proceed as follows:

- Unscrew the nuts (1). Disconnect the electrical

con nections of cables (2), (3), (4), (5) a nd (6).

- Remove the starter motor by unscrewing the nuts (1).

Fitting

- Change the motor with a new one and position it in its

seat after chang ing the gasket between the flywheel

housing and the motor. Tighten the fixing nut (M12 x

1.75) to a torque of 105 ÷ 86 Nm.

!

Before proceeding to work on an electric or

electronic component, make sure the system is not

powered.

It is recommended to mark t he cables in order to

make a secure connection in the assembly phase.

Figure 36

REMOVING/REFITTING STARTER MOTOR

Removal

NOTE

NOTE

NOTE

Always change the gasket w it h a new one. Do not

reuse the one removed.

98

SECTION 3 - INDUSTRIAL APPLICATION

VECTOR 8 ENGINES

Base - April 2006 Print P2D32V001E

Loading...

Loading...