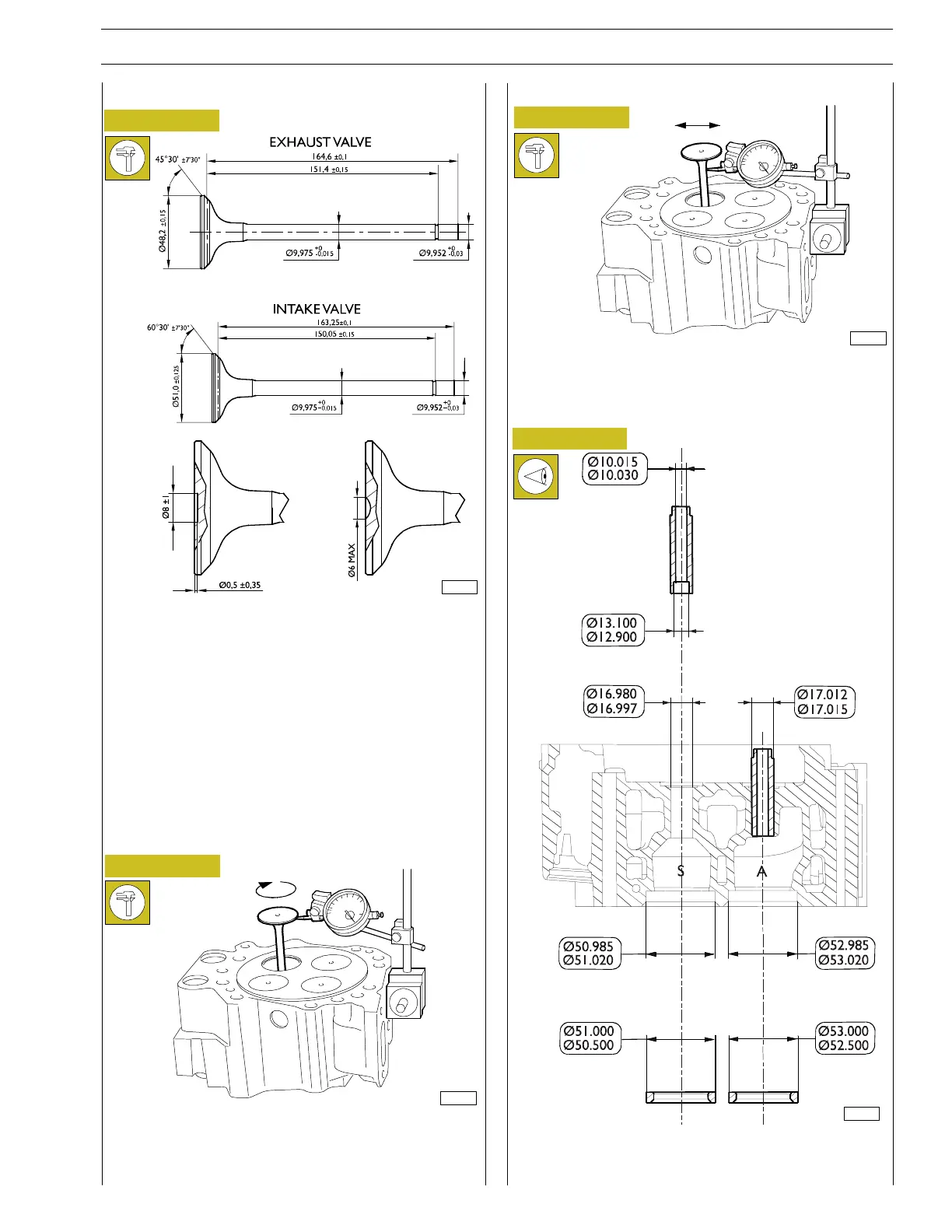

Figure 79

VALVE GUIDES

These checks are carried out using a magnetic support dial

gauge which is positoned as shown in the figure above.

By rotating the valve check that the centering error does not

exceed 0.03 mm.

Figure 80

Checking valve centering

Figure 81

These checks are carried out using a magnetic support dial

gauge which is positoned as shown in the figure above.

The mounting clearance is from 0.045 to 0.070.

Checking clearance between valve stem

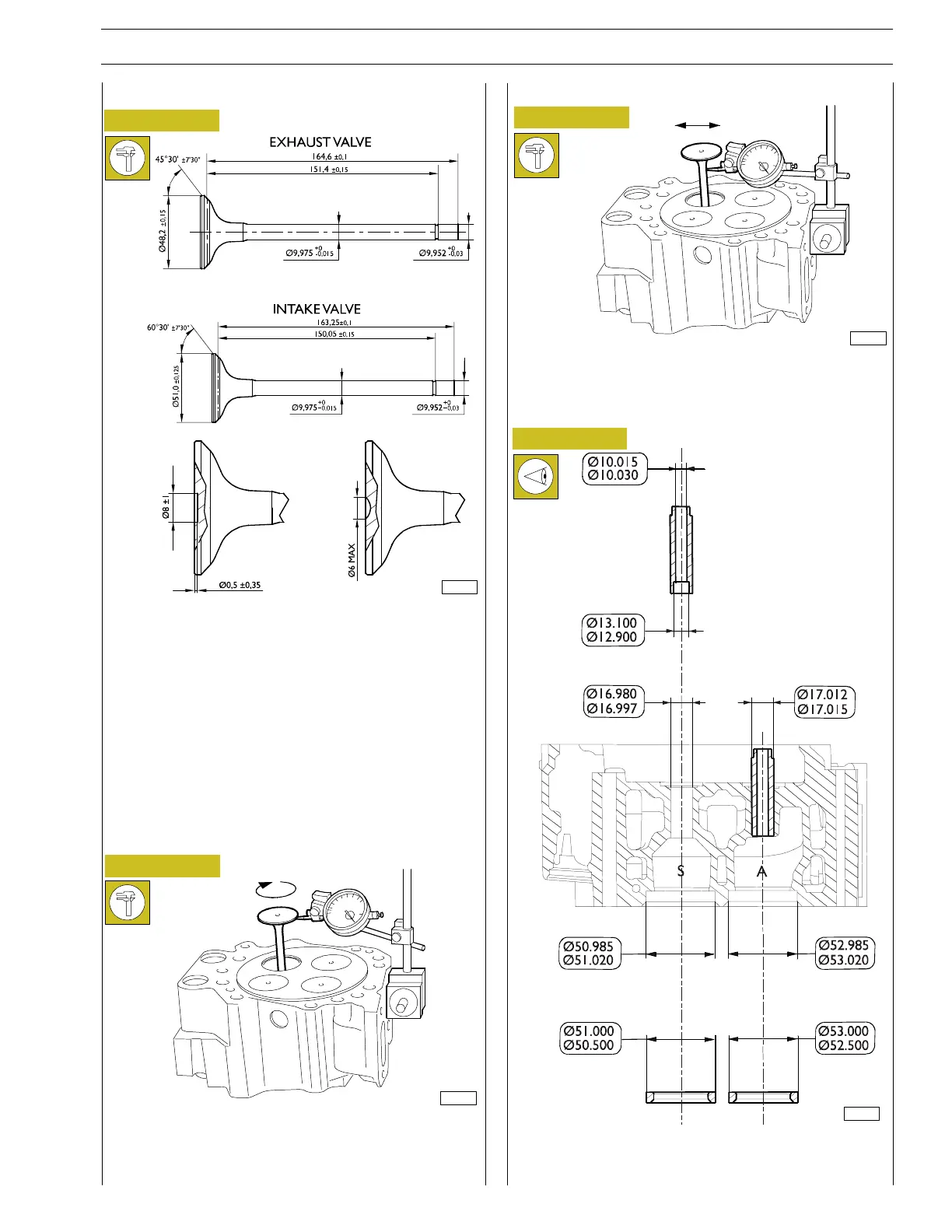

Figure 82

Refacing the valves

MAIN DATA OF THE VALVE SEATS AND VALVE GUIDE

SEATS ON THE CYLINDER HEADS

A=INLET—S=EXHAUST

A. Intake valve on the engines with serial numbers starting up

to 484 - B. Intake valve on the engines with serial numbers

starting from 485

- Check with a micrometer that the diameter of the valve

stems is as indicated; if necessary, rebore the seats on the

valves with the grinding machine, removing as little material

as possible.

After machining, check that the dimensions c ome within

thepermissibletolerance.

A

B

103185

89832

83492

89766

SECTION 4 - OVERHAUL AND TECHNICAL SPECIFICATIONS 35

VECTOR 8 ENGINES

Print P2D32V001E Base - April 2006

Loading...

Loading...