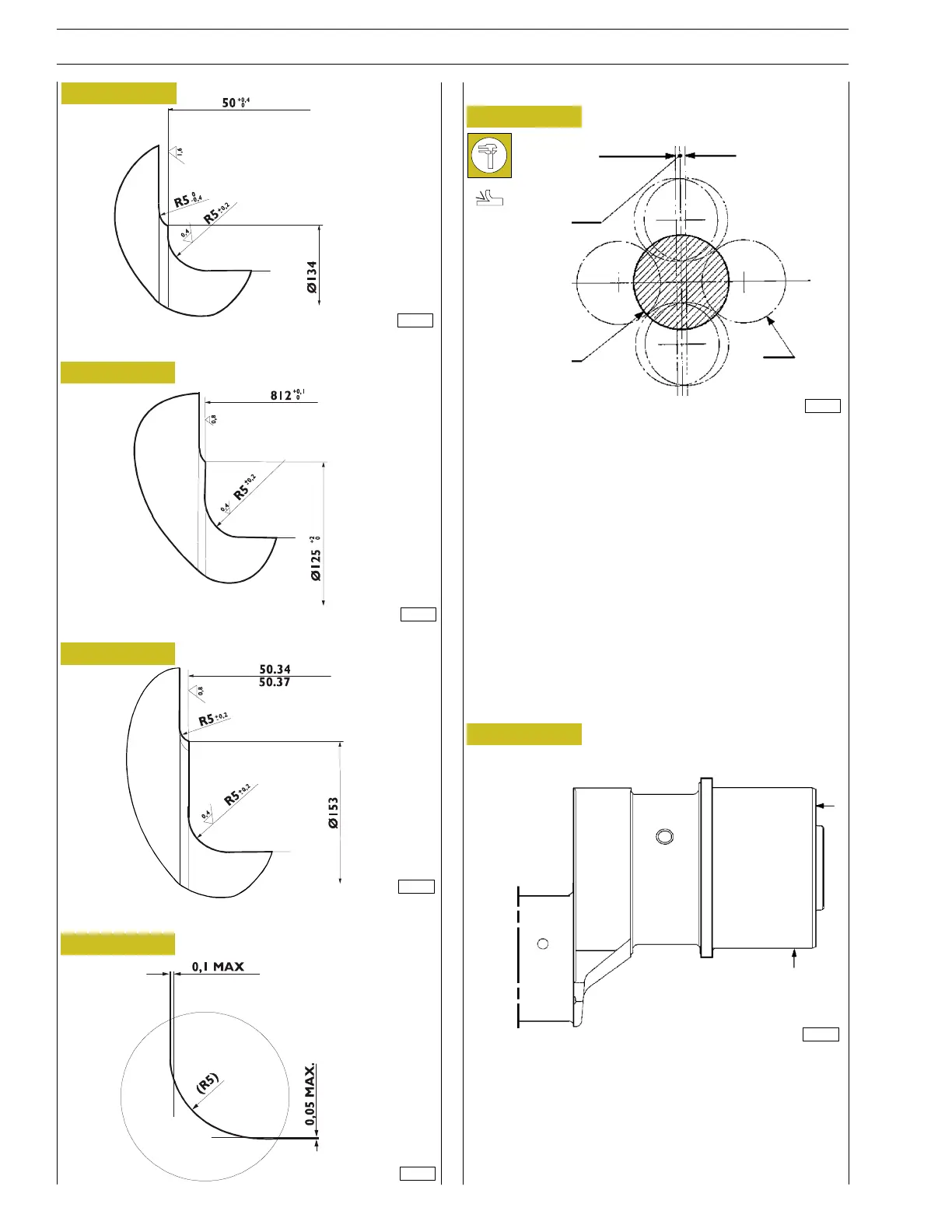

The tolerances allowed on the engine shaft pins are:

- ovality = 0.007 mm

- taper 0.012 mm

- main journal misalignment 0.10 mm

- crankpin misalignment ± 0.025 mm

- tolerance on the distances between the axis of the

crankshaft and the outside of each crankpin ± 0.10 mm

Figure 23

Figure 24

Figure 25

Detail of couplings of central main journal.

Detail of couplings of crankpin.

Detail of couplings of rear — thrust main journal.

Checking main journal alignment

LIMIT POSITION

LIMIT POSITION

NORMAL POSITION

MAIN JOURNAL

CRANKPIN

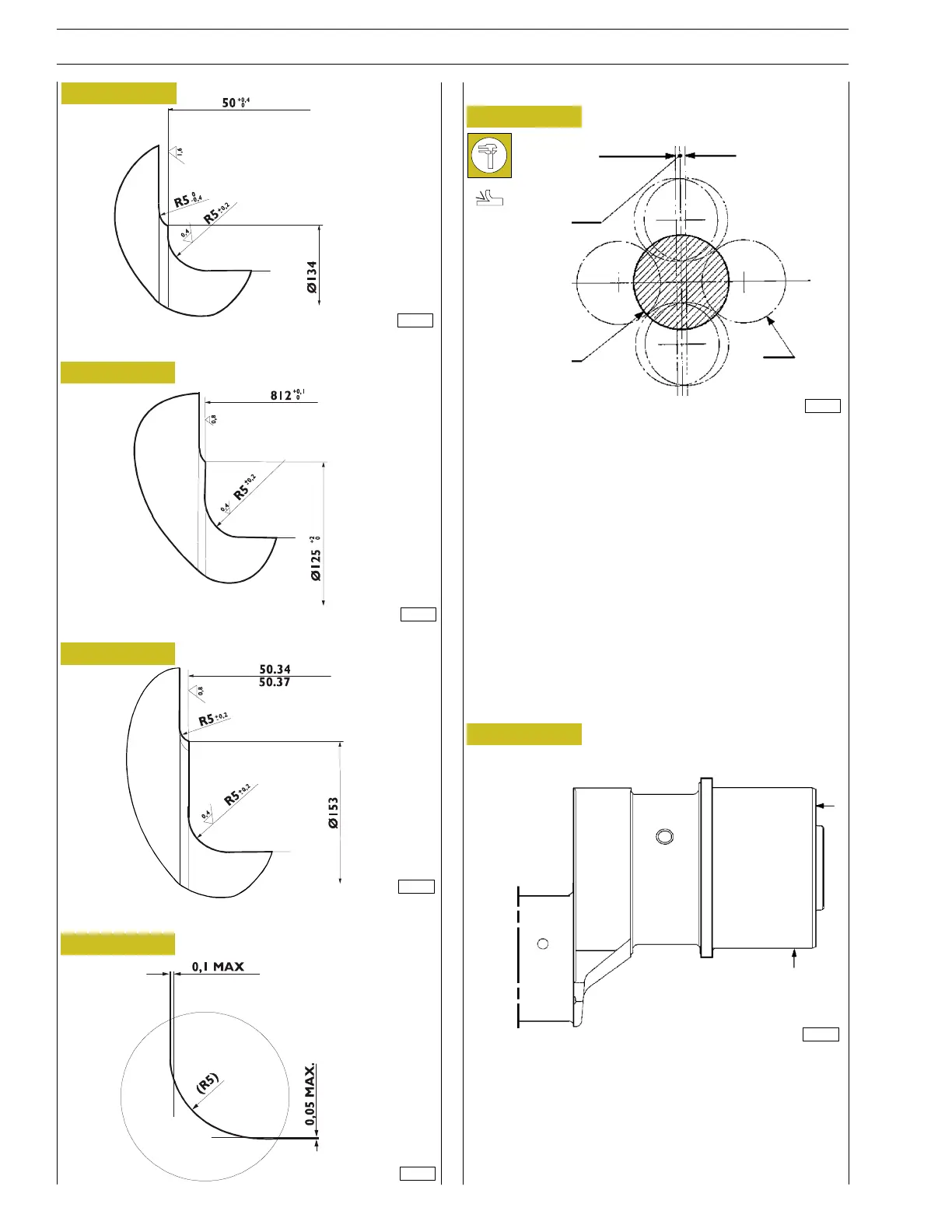

Diagram for checking the flywheel mating surface is orthogonal

and coaxial with the axis of rotation and main journals.

Turn the shaft:

- with the dial gauge at B no change greater than 0.04 mm

must be measured on the dial gauge;

- with the dial gauge at A no change greater than 0.03 mm

must be measured.

Figure 26

Figure 27

Figure 28

B

A

0.025

0.025

83496

8296

83495

83494

8297

83493

18

SECTION 4 - OVERHAUL AND TECHNICAL SPECIFICATIONS

VECTOR 8 ENGINES

Base - April 2006 Print P2D32V001E

Loading...

Loading...