Figure 1

Figure 2

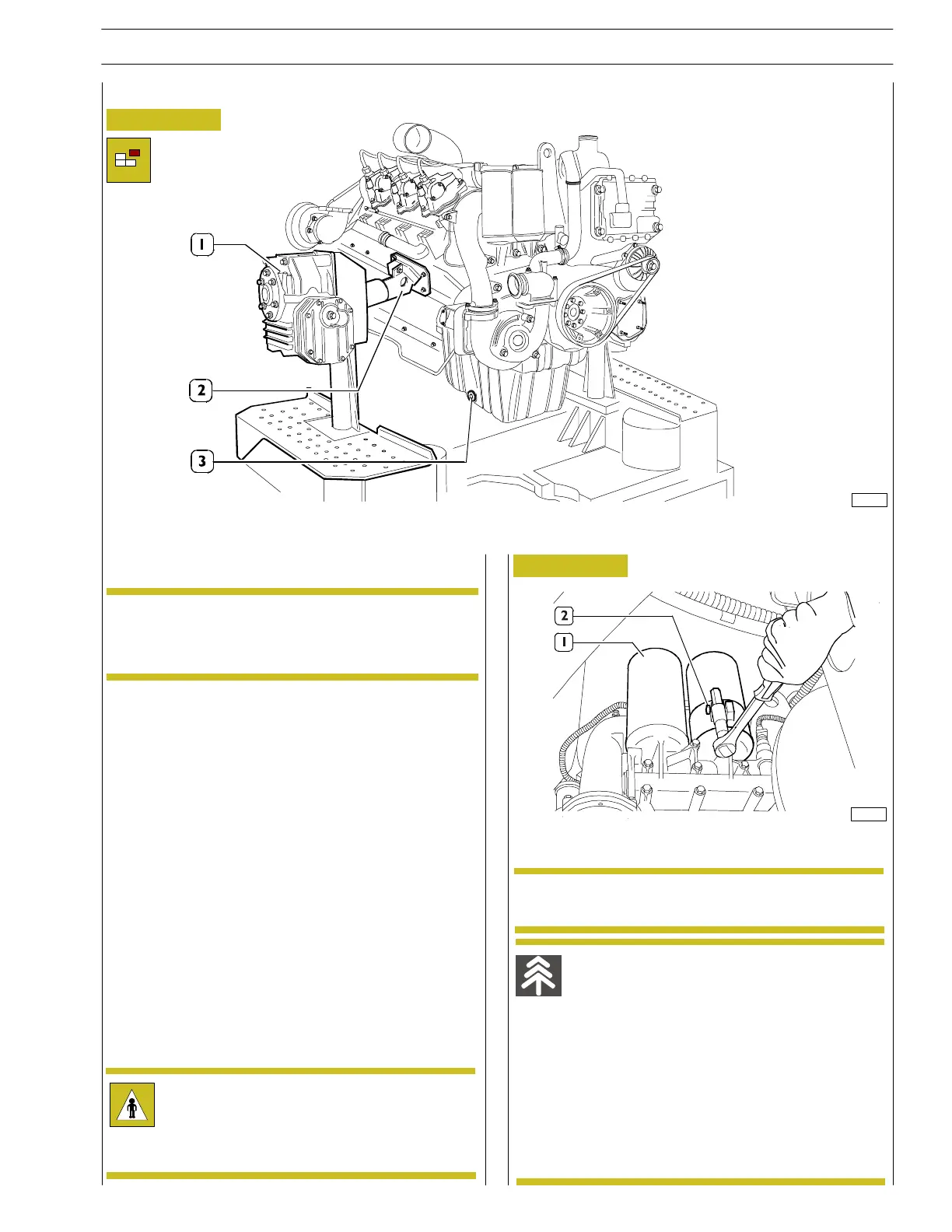

Dismantling

- Remove the protective grilles from the exhaust

manifolds and from the turbochargers from the engine.

- Remove the dipstick complete with guide pipe from the

sump.Also remove t h e oil filler.

Seal appropriately to prevent particles of dirt from

entering.

- Secure the engine to t he rotary stand 99322230 (1) with

the brack ets 99361011 (2); drain off the lubrication oi l

from the engine sump through the plug (3).

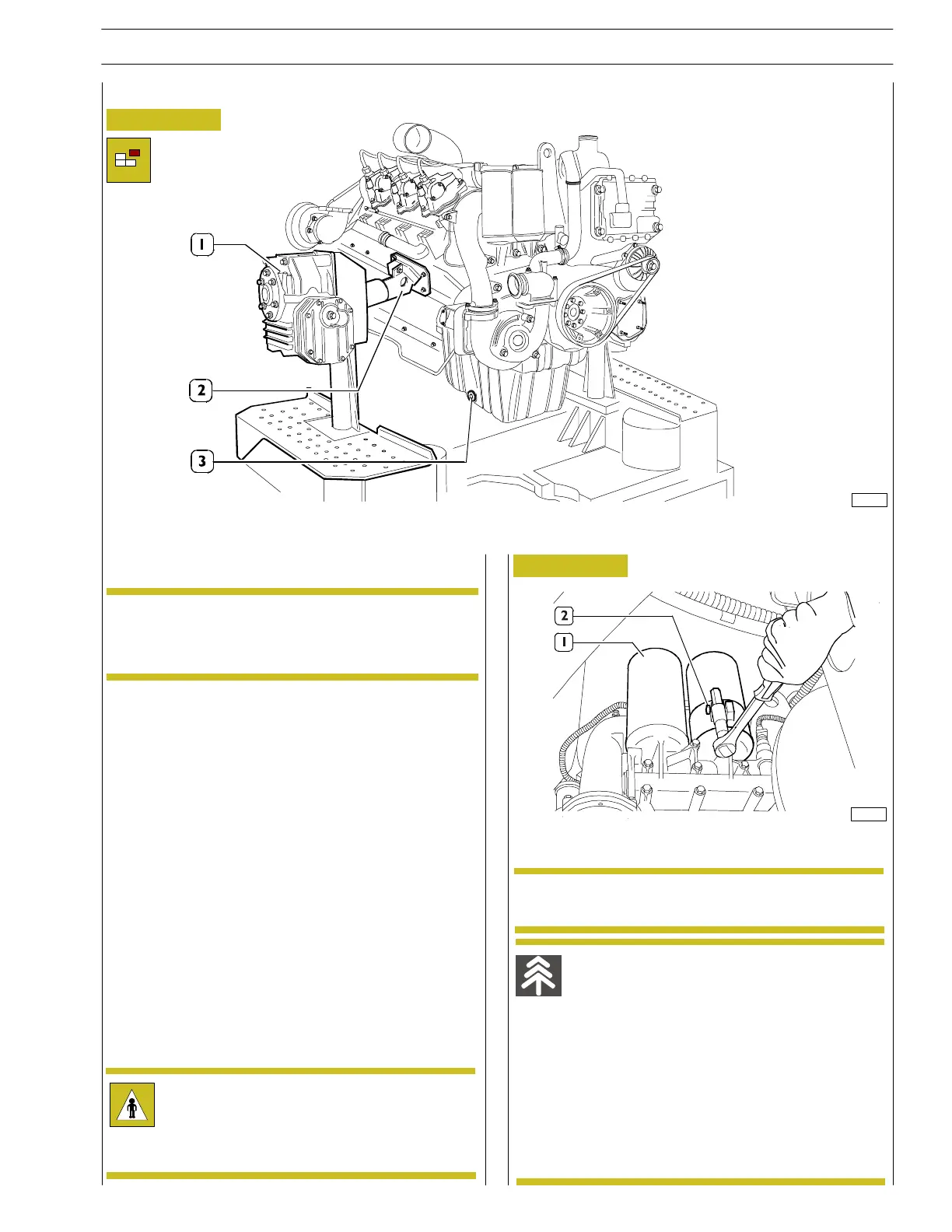

- Remove the o il filters (1) u sing the special

tool 99368501 (2).

Before disassembling, place under the filter a basin

of suitable capacity.

Improper waste disposal is a threat for the

environment. Potentially hazardous waste includes

lubricants, fuels, c oolan ts, filters and batteries.

— Use watertight containers when draining off

fluids. Never use containers for foodstuffs or

beverages that can lead people to drink from

them.

— Never throw waste on the ground, on tips or

in water c ou rses.

— Obtain information on the appropriate ways

of recyc lin g or dispo sin g of waste from the

local authorities or c o llect ion centres.

103226

82196

Handle all components very carefully. Do not put

your fingers between different components. Always

wear recommended protective clothing such as

goggles, gloves, safety shoes and protective

headgear.

The following information relates to th e engine overhaul

operations only for what concerns the different components

customising the engine, acco rding to its specific duties.

In section ”General overhaul”, all the operations o f engine

block overhaul have been c ontemplated. Therefore the

above mentioned section is to be considered as following the

part hereby described.

All operations of E ngine disassembly operations as

well as overhaul operations must be executed by

qualified technicians provided with the specific

tooling and equipment required.

Preface

NOTE

NOTE

ENGINE OVERHAUL

SECTION 3 - INDUSTRIAL APPLICATION

11

VECTOR 8 ENGINES

Print P2D32V001E Base - April 2006

Loading...

Loading...