Figure 33

Figure 34

α

Finding journal clearance

Check the clearance between the crankshaft main journals and

their respective bearings as follows:

- thoroughly clean the pins;

- apply a calibrated wire (2) on the main journals (1);

- fit the caps (1) of the main bearing housings with the half

bearings so that the stamped numbers face the same side

as the corresponding ones on the cylinder assembly;

- Lubricate under the bottom side of the heads of screws

(2 an d 3) that fix the bench caps with engine oil and

tighten to the fixing torque prescribed;

When tightening to an angle, use tool 99395216.

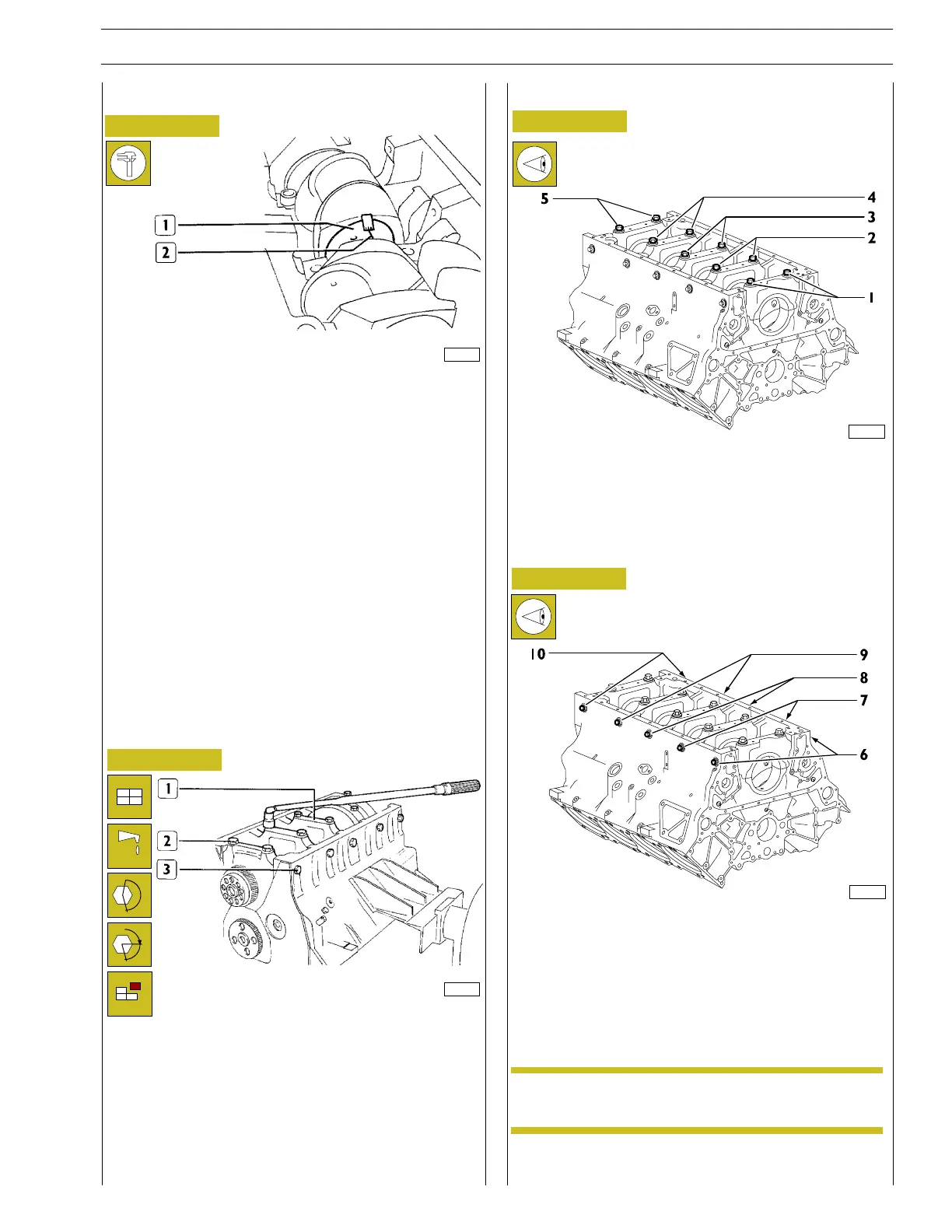

Figure 35

Tightening sequence

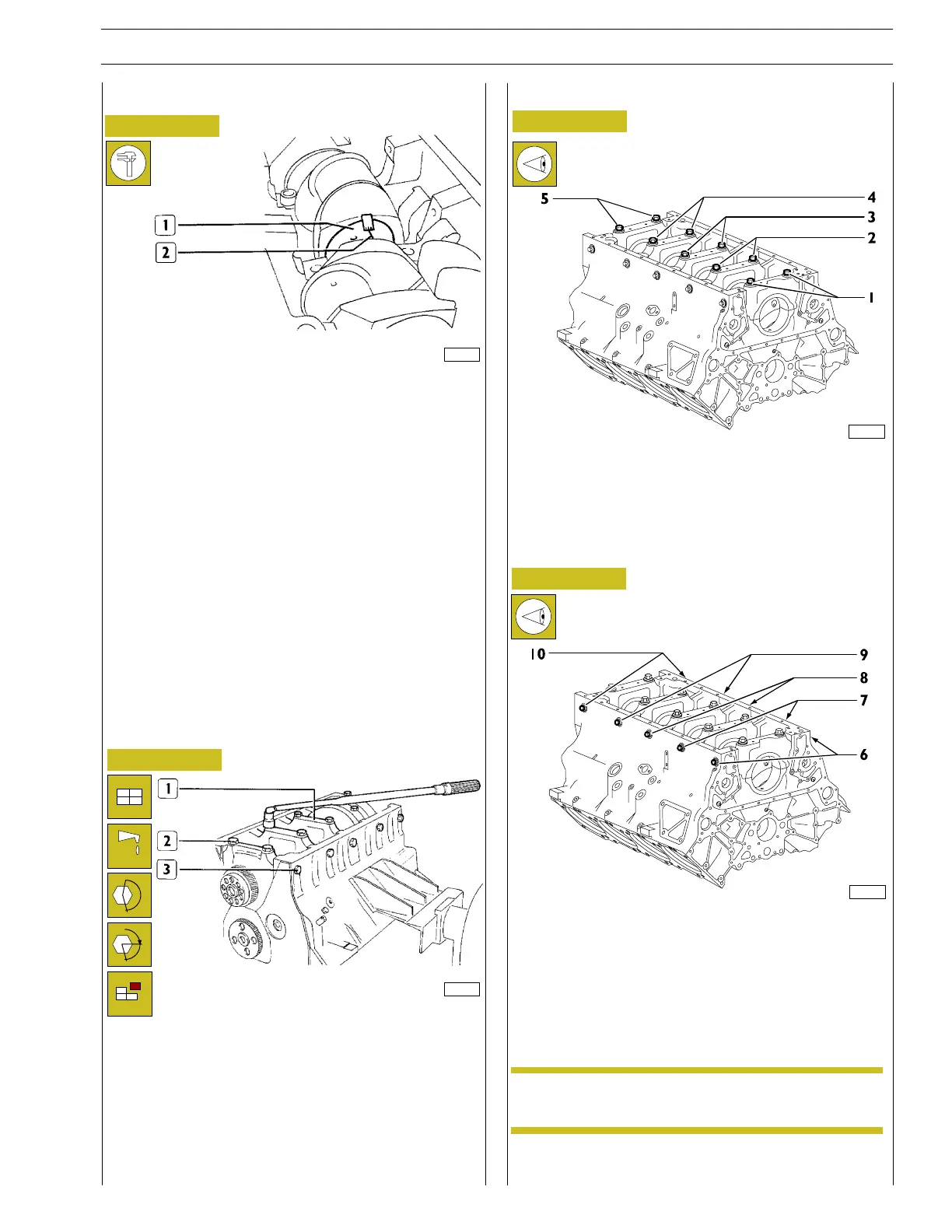

Figure 36

M20x1.5 bolts

Type of tightening: pre-torque + angle

Pre-torque 160Nm

Angle 240˚

Guard-torque 600 ÷ 1000 Nm

M16x1.5 bolts

Type of tightening: pre-torque + angle

Pre-torque ~70Nm

Angle 120˚

Guard-torque 240 ÷ 460 Nm

16813

89797

89796

16886

NOTE

SECTION 4 - OVERHAUL AND TECHNICAL SPECIFICATIONS 21

VECTOR 8 ENGINES

Print P2D32V001E Base - April 2006

Loading...

Loading...