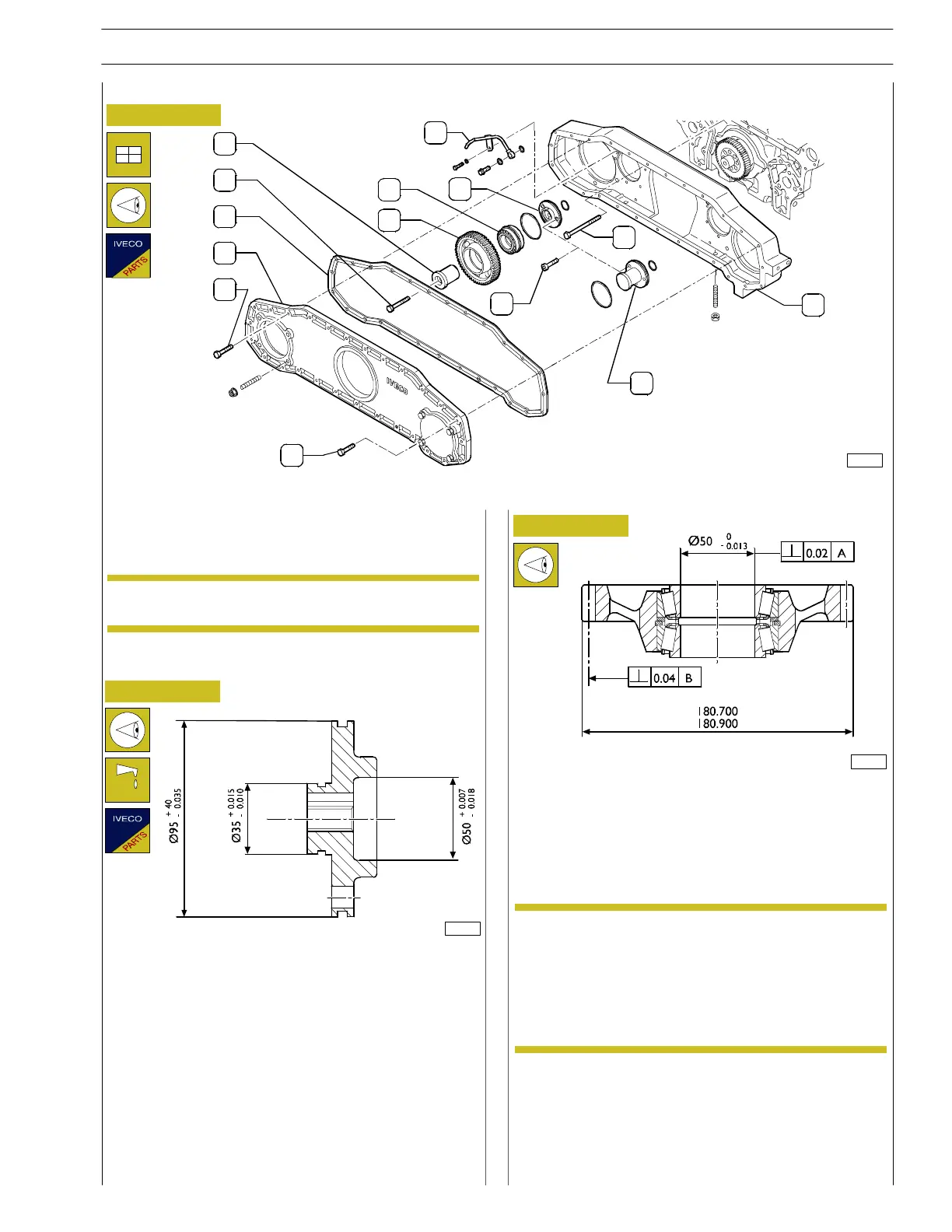

Figure 47

103193

1

1

2

3

4

6

7

8

5

12

13

9

10

11

- Check the dimensions of the parts removed, examining

their state of wear.

Replace all the seals and O-rings.NOTE

- Check the spacer (8, Figure 47): check the state of wear

of the zones of contact with the shaft (5) and the

dimensions as shown in the figure.

- Insert the new O—rings in their seats on the spacer (1)

and, with the aid of a drift, go ahead with assembly on the

crankcase.

- Tighten the spacer fixing screws to the prescribed torque:

M10x1.5x25 mm cheese—headed screws: 45 to 50 Nm.

Lubricate the screws with ” UTDM” oil o r alternatively

with engine oil.

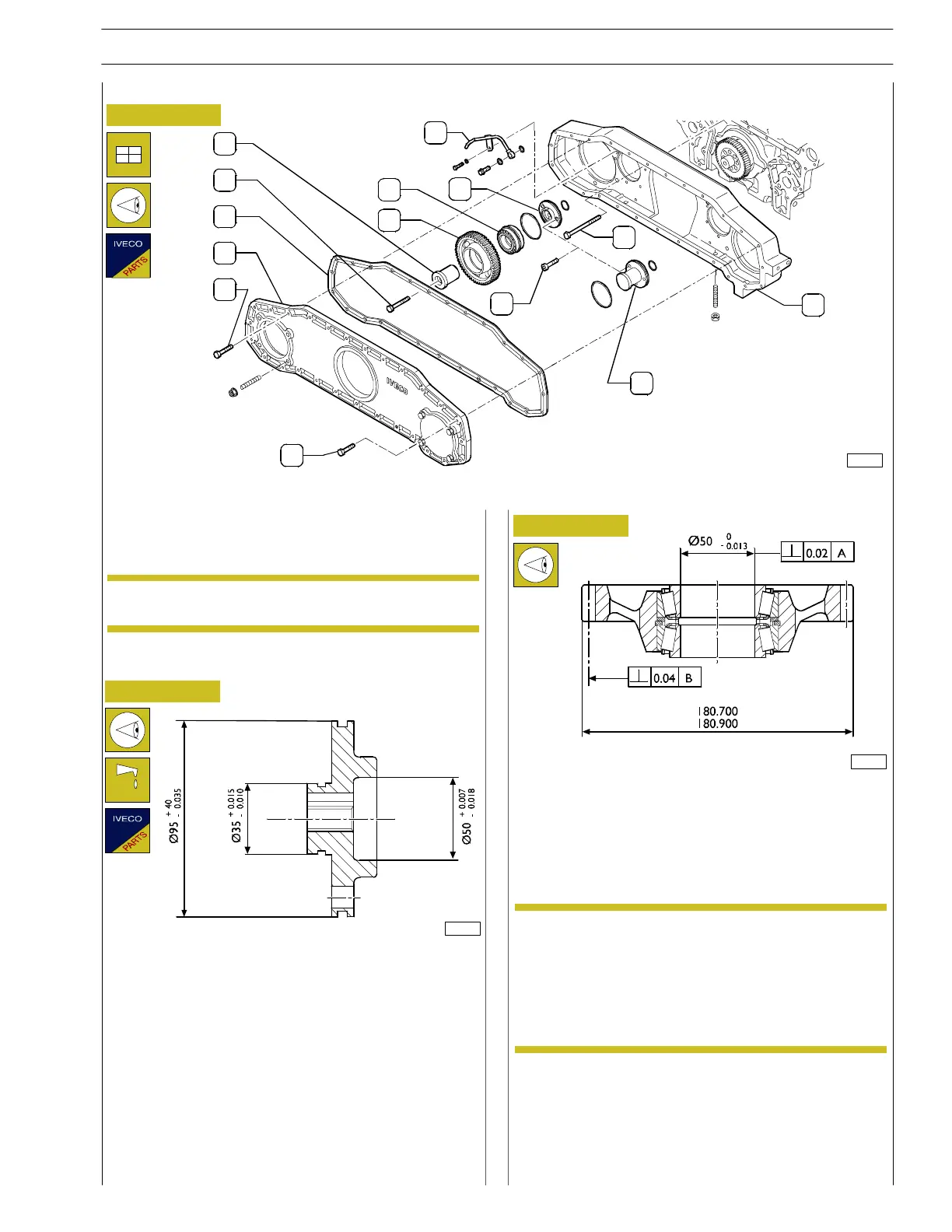

Figure 48

82248

Figure 49

82250

- In addition, check the state of wear of both the bearings

and th e gears. If there is noisiness or clear seizure of the

gears, replace th em.

- Check the state of wear of the teeth of the gears and the

contact surface between the inside of the bearing and

the shaft.

NOTE

The conical roller bearings and the gear are supplied

as spares already fitted.

The gear has the following dimensions:

-outer diameter 180, 700 P 180,900 mm;

-No. of teeth 34.

Fitting the gearbox

SECTION 3 - INDUSTRIAL APPLICATION

25

VECTOR 8 ENGINES

Print P2D32V001E Base - April 2006

Loading...

Loading...