112-14

Section F Transmission

9803/3280

Section F

112-14

Issue 1

Synchro Shuttle Gearbox

Assembly (cont'd)

Note: It is recommended that a 75 micron (0.075mm)

service suction strainer (892/00970) is fitted to clean the

system after a major overhaul.

Remove the service strainer and fit a production strainer

after the first 100 hours operation. Renew the oil.

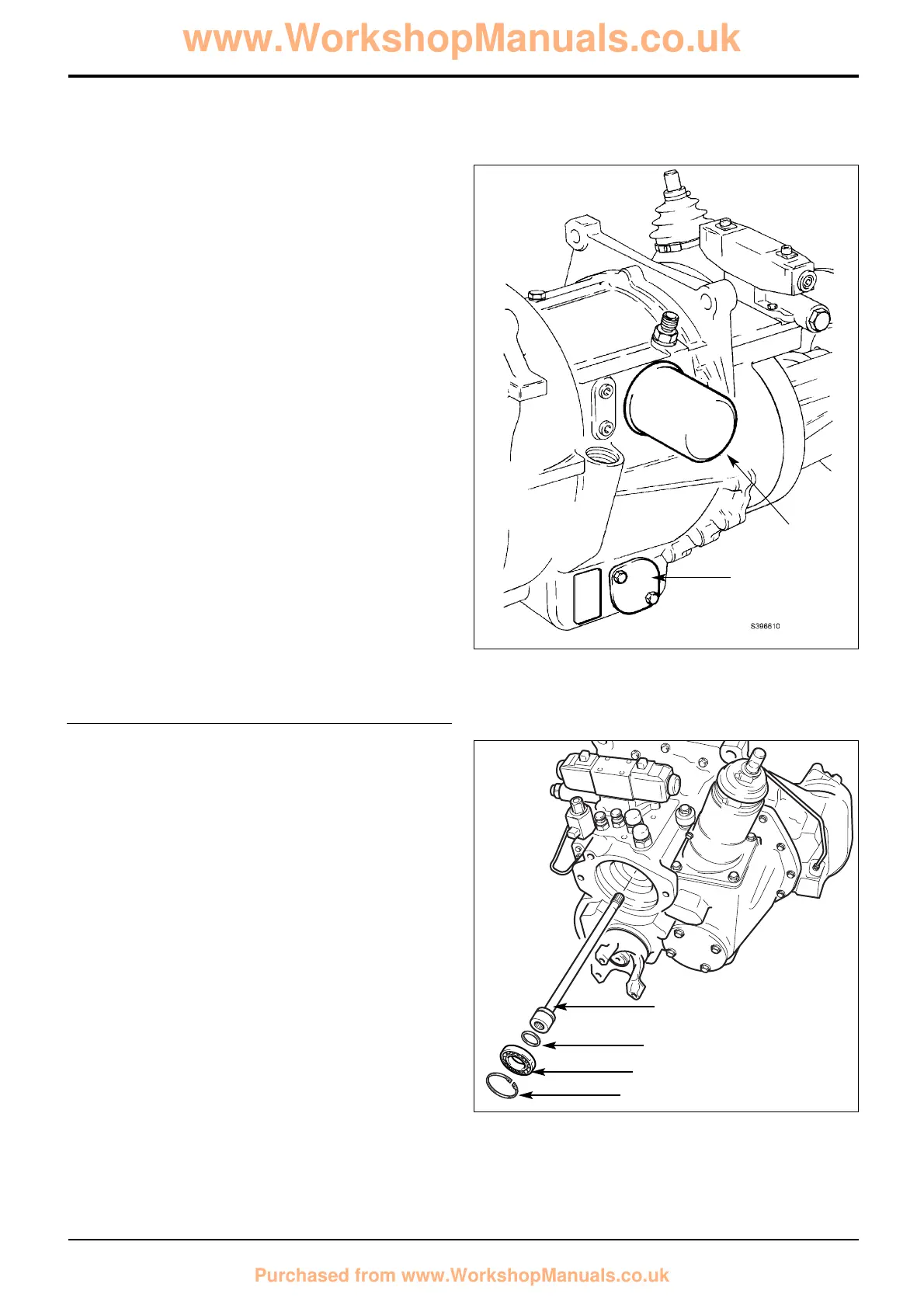

47 Using a new gasket, install suction strainer. Apply JCB

Threadlocker and Sealer to bolts and tighten to 10 Nm

(7 lbf ft).

48 Fit a new filter:

a Smear seal with transmission oil.

b Screw the filter on until it just contacts the filter

head.

c Turn the filter at least another 3/4 of a turn.

49 Install dipstick/oil filler tube (not shown) as follows:

a Fit nut to tube followed by seal.

b Insert tube fully down bore in casing. Engage nut

and tighten down loosely onto seal.

c Tighten nut fully after tube has been correctly

phased.

See 2/4 Wheel Drive Clutch for hydraulic 4WD

dismantling and assembly procedures.

47

48

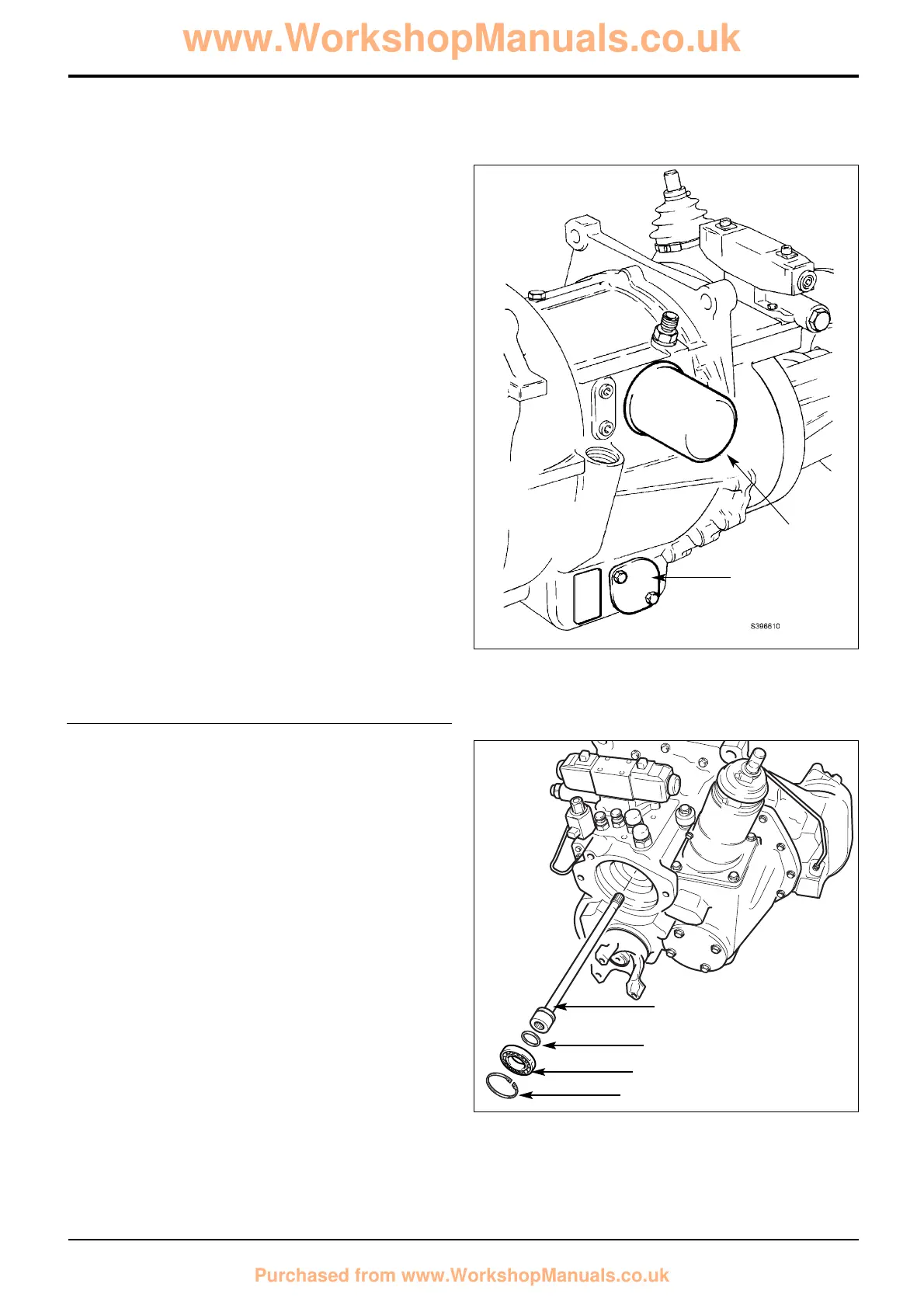

50

50a

50b

50c

50 Fit a new sealing ring 50a to the pump drive shaft. Insert

the pump drive shaft followed by bearing 50b and

circlip 50c.

Note: The main hydraulic pump may be fitted at this stage,

or, after the gearbox has been refitted to the machine.

Loading...

Loading...