6 - 2

Syncro Shuttle Gearbox

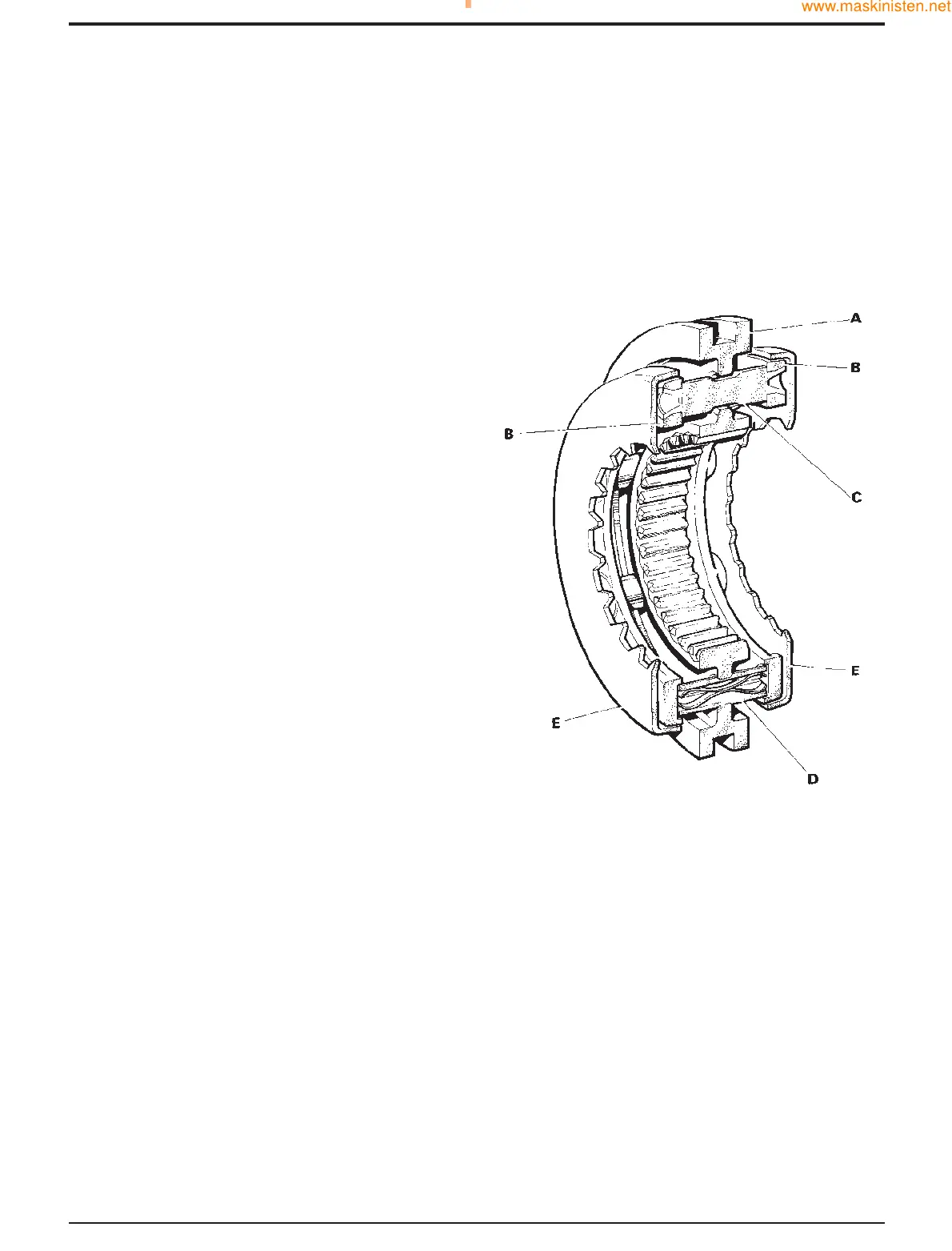

Synchromesh - Operation

The gearbox is fitted with 'Blocking Pin' synchromesh,

comprising the following parts.

SYNCRO HUB (A) controls the operation of the

synchromesh unit and gear selection, the selector fork fitting

into the outer groove. Internal dog teeth link the selected

gear to the drive shaft. Through the syncro hub centre are

two sets of holes for the blocker pins (C) and the split

energiser pins (D), spaced alternately.

SYNCRO RINGS (B) are rigidly joined by the blocker pins,

with the split energiser pins held, in counterbores, between

the two syncro rings.

BLOCKER PINS (C) have a narrow neck in the centre,

against which the syncro hub transmits radial drive during

gear changes. The edges of the blocker pin neck and their

mating syncro hub holes are designed so that, as the radial

loads are reduced, the syncro hub can slide over the

shoulder of the blocker pin.

SPLIT ENERGISER PINS (D) take the initial axial load of the

syncro hub on the shoulder of the split energiser pin neck.

As the axial load reaches approximately 400 N (40.8 kg; 90

lb) the internal springs allow the split energiser pin to

collapse and the syncro hub to move axially.

SYNCRO CUPS (E) take the frictional drive from the syncro

ring on their inner faces. The syncro cups are splined to

drive their respective gears whilst synchronisation is taking

place.

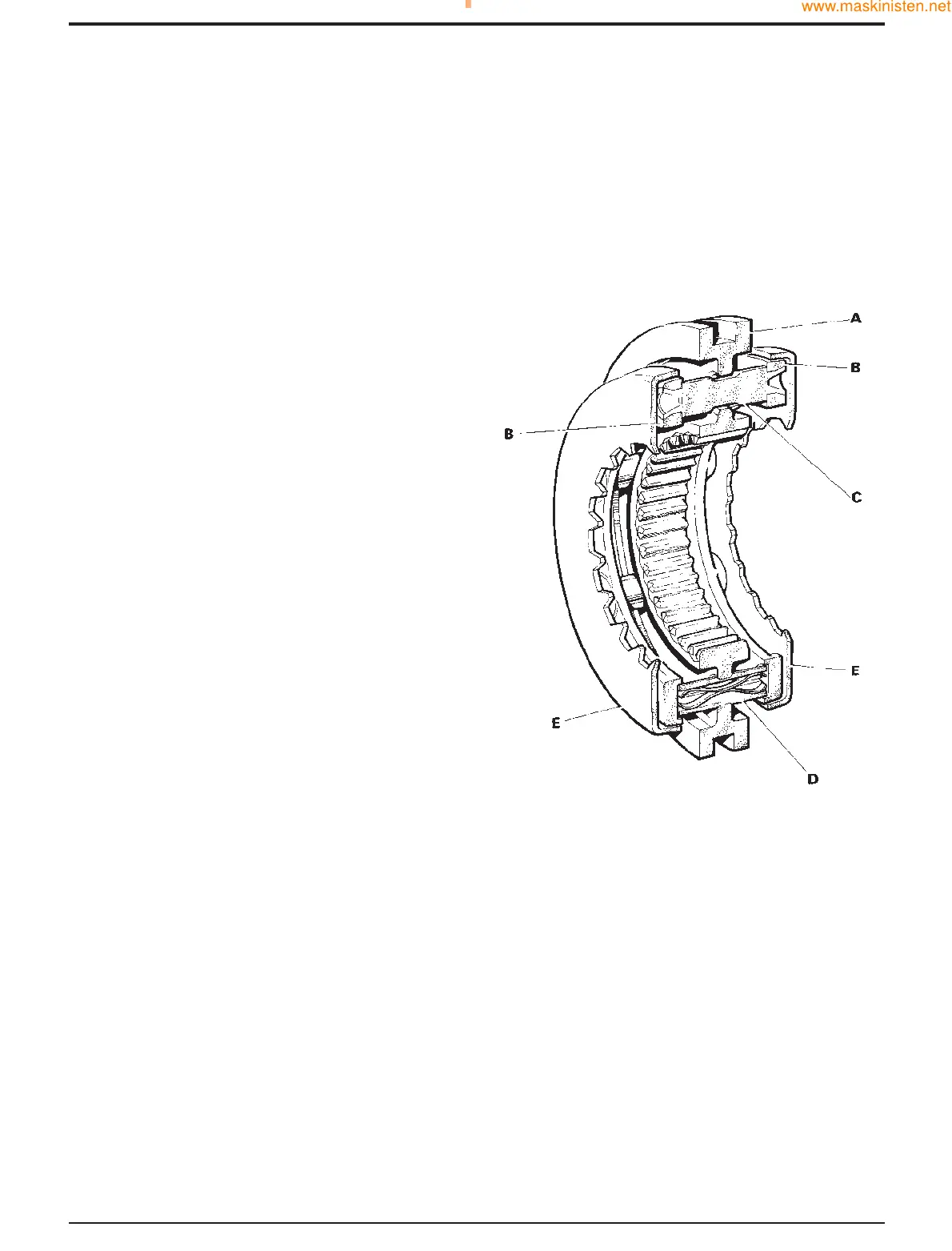

SYNCHROMESH - OPERATION

Diagram F shows the gearbox with first gear engaged.

Syncro ring B is in contact with syncro cup E and the syncro

hub dog teeth are linking first gear to the shaft gear. In this

position the split energiser pins D are 'collapsed'.

When selecting second gear the syncro hub A slides along

the split energiser pins until the pin recess and the syncro

hub flange are in line. At this point the split energiser pins

open and the syncro rings are moved by the syncro hub

pushing on the split energiser pin shoulder.

Initial contact between the syncro ring and the syncro cup

starts to synchronise the speed of the shaft and second

gear. The rotational force of the syncro ring is taken by the

blocker pin against the edge of the syncro hub hole, as at G.

As the axial load on the syncro hub increases, the split

energiser pin 'collapses' and the conical faces of the

blocking pin and syncro hub hole come into contact, as at

H.

Further increases in the axial loads increase the frictional

grip of the syncro ring and the syncro cup, causing the shaft

and gear speeds to synchronise.

As the speeds are synchronised the radial load on the

blocker pin and the syncro hub is reduced. This allows the

syncro hub to slide freely along the blocker pin and engage

its dog teeth with second gear, see diagram J.

Section F Transmission

9803/7130

Section F

6 - 2

Issue 1

Systems Description

Loading...

Loading...