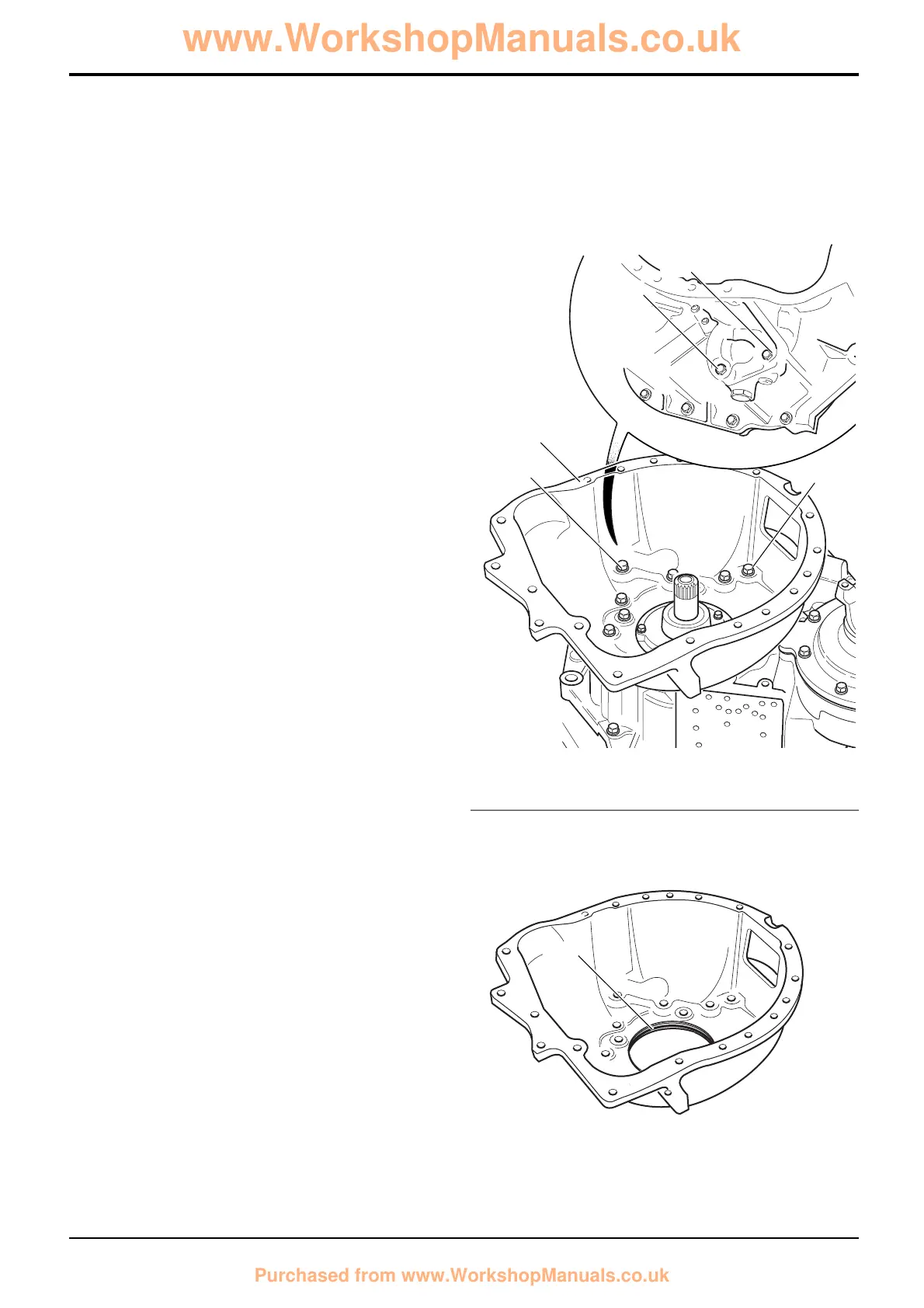

10 Fit the Torque Converter Housing - Gearboxes with

18 bolt fix only

Important Note: Only the specified sealant can be used. The

machine MUST NOT be operated for at least 6 hours after

sealant has been applied and the converter housing

assembled. This is to allow time for the sealant to cure.

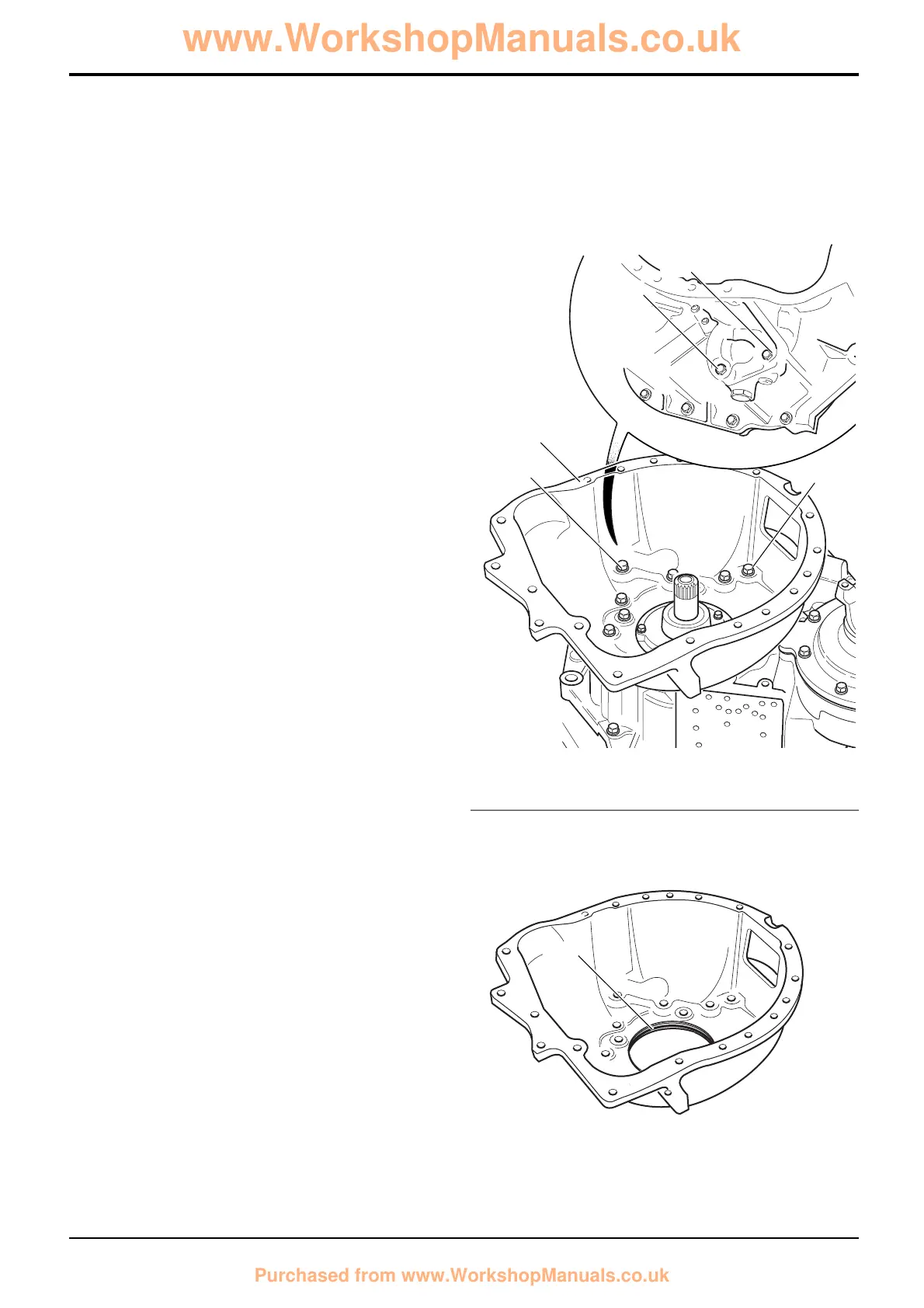

a Make sure that the front case and torque converter

housing (10a) mating faces are clean, dry and

undamaged. Apply a 3 mm wide bead of Bondloc B574

sealant to the front casing as shown at A (pump not

shown for clarity). Make sure that sealant is applied

between all the port channels as shown. Take extra

special care in the area X as sealing is critical in these

areas. Be sure not to block galleries with sealant. Fit a

new ‘O’ ring 10d to the housing 10a.

b Carefully locate the torque converter casing on the front

case. Fit new 10.9 grade bolts as follows:

M10 bolts 10b (15 off). Note that spacers are fitted

under bolts at positions 10 and 14.

M8 bolts 10c. (3 off)

Progressively torque tighten the bolts in the sequence

shown. Note that the bolt at position 1 is re-torqued

after tightening the bolt at position 15.

Sequence Bolt Position Torque

(shown at B)Nmlbf ft

1 - 9 1 - 9 78 57.5

10 10 60 44.25

11 - 13 11 - 13 78 57.5

14 14 60 44.25

15 15 78 57.5

16 1 (Re-torque) 78 57.5

17 - 19 17 - 19 38 28

127 - 10

Section F Transmission

9803/3280

Section F

127 - 10

Issue 3*

Powershift Gearbox

Assembly (cont’d)

10a

10c

10c

10c

10b

Loading...

Loading...