– 6 –

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power o and ascertaining that the motor is at rest.

2-4. Pneumatic components (Only for the models provided with the stitch skipping

detecting device and bobbin-thread remaining amount detecting device)

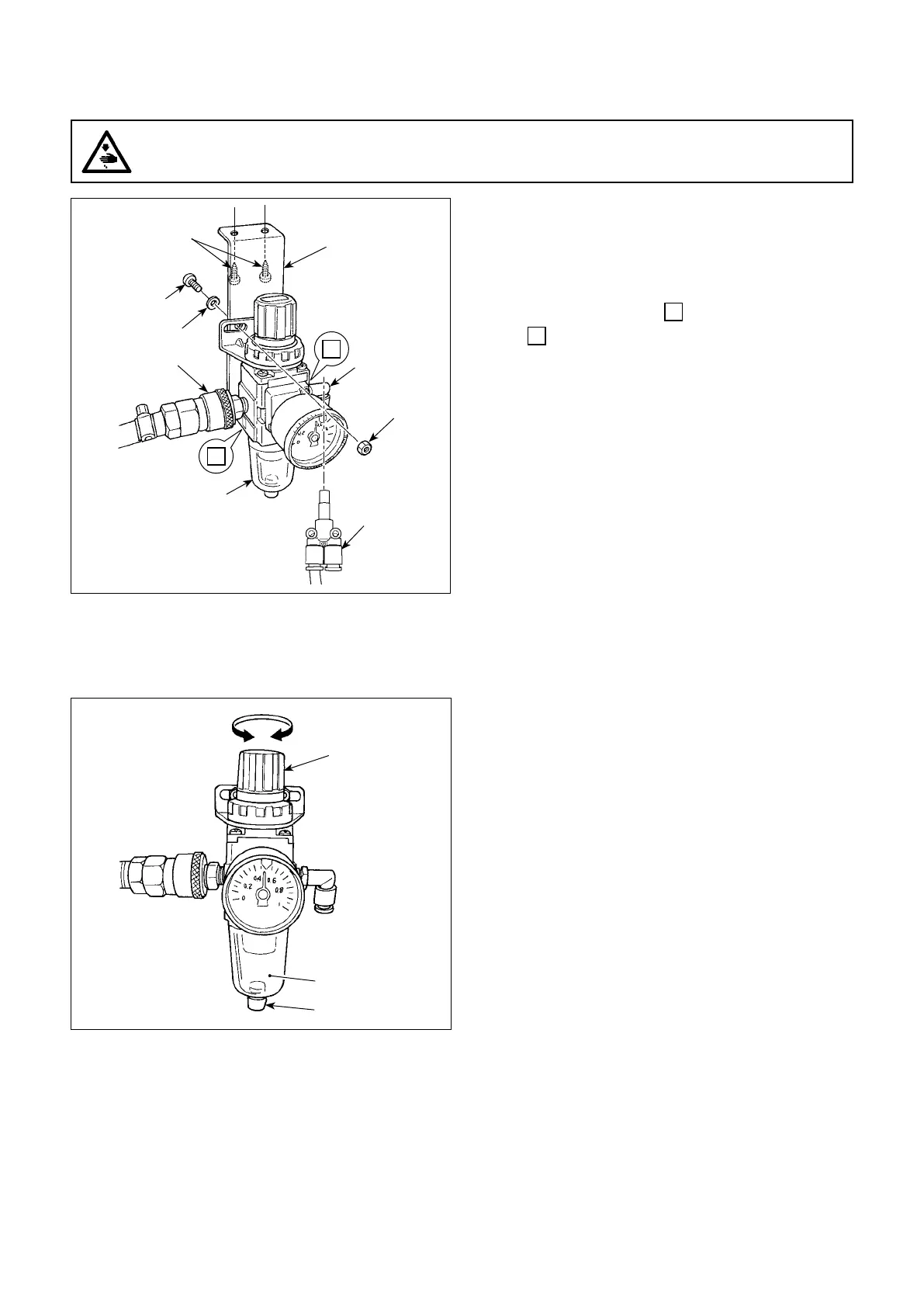

(1) Installing the regulator

1) Install regulator (asm.)

❶

on mounting plate

❺

with screw

❷

, spring washer

❸

and nut

❹

which are supplied with the unit.

2) Attach joint

❻

to inlet

1

. Attach joint

❼

to out-

let

2

.

3) Attach mounting plate

❺

on the undersurface of

the table with accessory screws

❽

supplied with

the plate.

4) Connect branch Y union

❾

to joint

❼

.

* Screw

❷

which is supplied with the unit:

Thread diameter M5; Length: 12 mm

(SM6051202TP)

* Branch Y union

❾

(PJ308060004) which comes

with the air blower solenoid valve asm._SD

should be used.

❶

❷

A

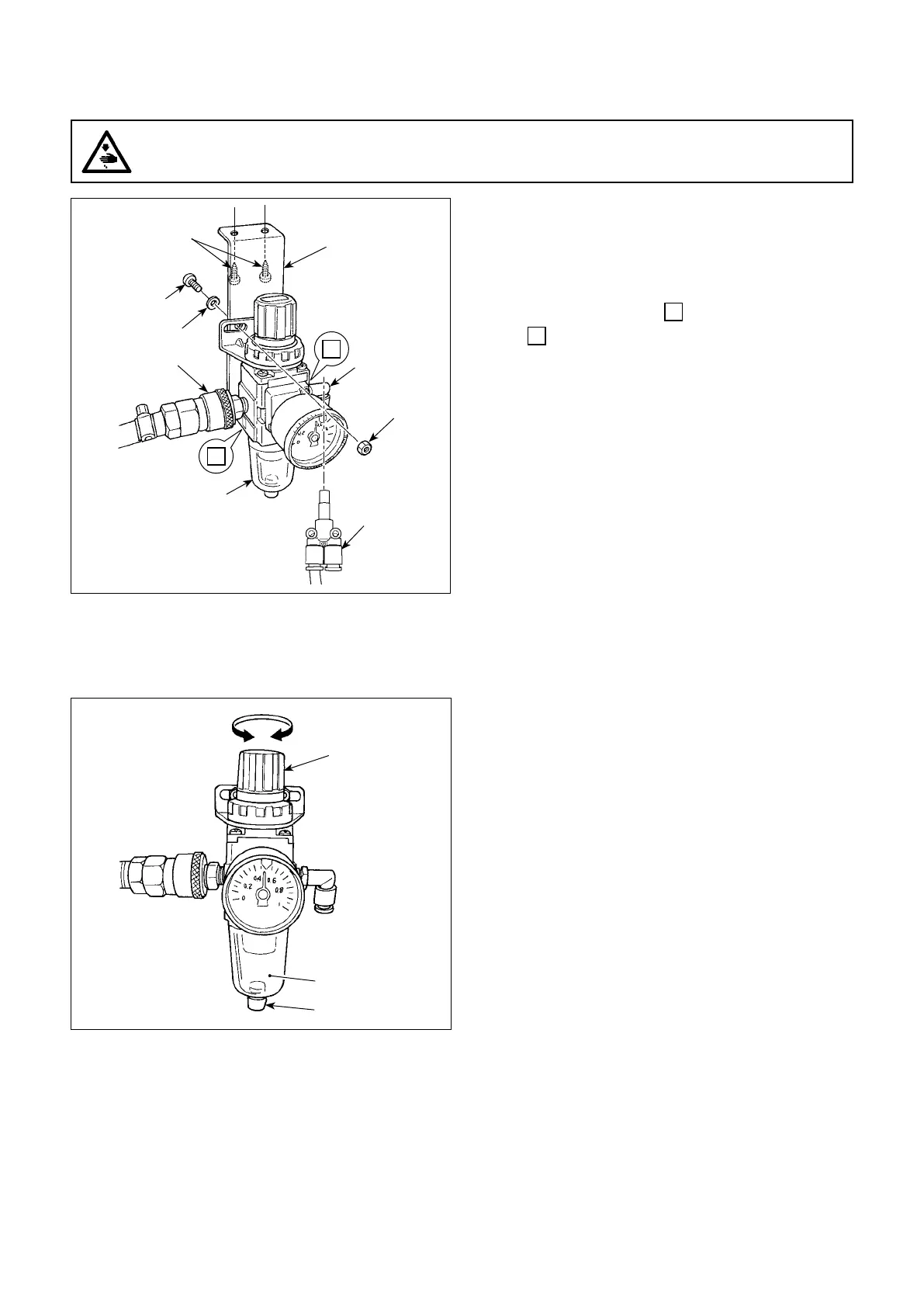

(2) Adjusting the air pressure

1) The operating air pressure is 0.5 to 0.55 MPa.

Adjust the air pressure using air pressure regu-

lating knob

❶

of the lter regulator.

2) In the case uid accumulation is observed in

A

section of the lter regulator, turn drain cock

❷

to drain the uid.

Decrease Increase

❷

❶

❺

❼

❻

❹

❸

❽

1

2

❾

Loading...

Loading...