– 3 –

2-2. Installation of the sewing machine

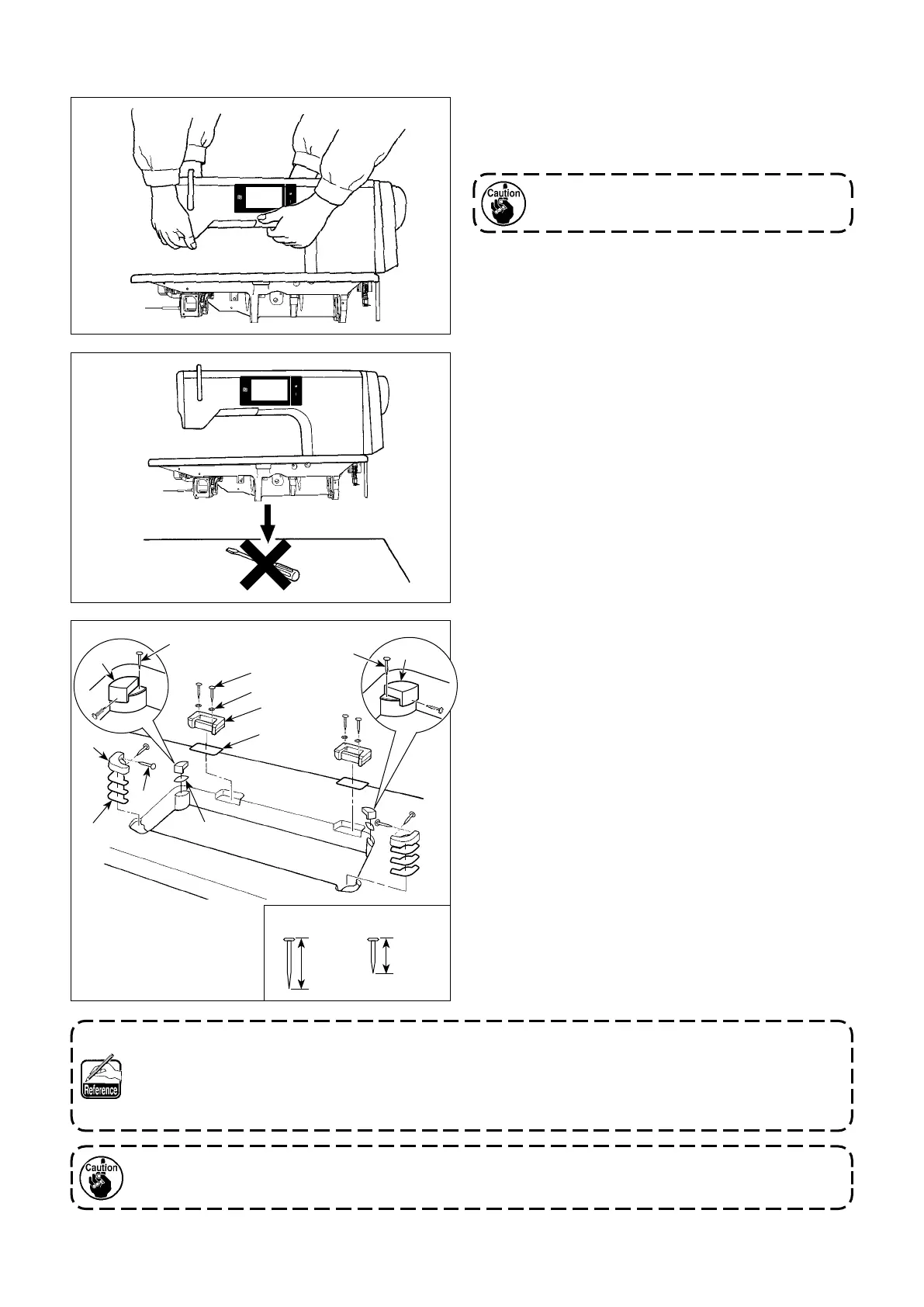

1) To prevent possible accidents caused by the full

of the sewing machine, perform the work by two

persons or more when the machine is moved.

2) Place the sewing machine on a horizontal and

plane place when placing it and do not place

any protruding thing such as a screwdriver or

the like.

Never hold the handwheel since it rotates.

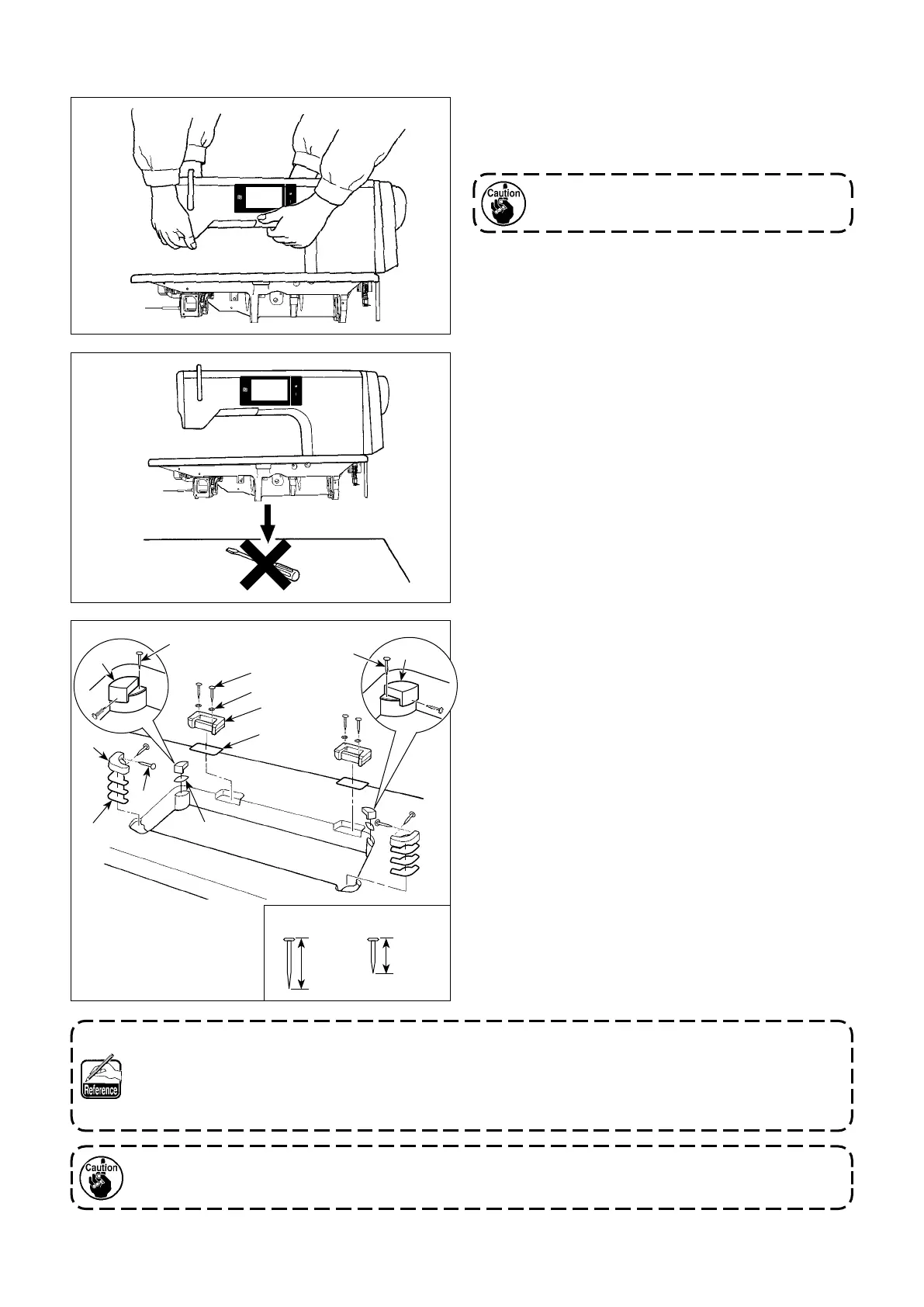

3) Attaching the hinge seats and the support rub-

bers of the machine head

Fix accessory hinge seat

❶

supplied with the

unit on the table with wood screw

❼

and wash-

er

❽

while placing sheet plate

❻

between the

hinge seat and the table as shown in the gure.

Fix machine head support rubbers

❷

and

❸

on

the table with nails while putting sheets

A

(stan-

dard: 3 pieces) and sheet

B

(standard: 1 piece)

under the machine head support rubbers.

Use nail

❺

for sheet

B

and nail

❹

for sheets

A

.

There are two dierent machine head support

rubbers

❸

; i.e., the rubber for the right and that

for the left. Be sure to check the types of the

support rubbers before xing them.

Sheet A (eight pieces) and sheet B (four pieces) are supplied with the machine as accessories.

For the sheet A, three sheets are to be used as standard for each mounting position. For the sheet B,

one sheet is to be used as standard. (The state shown in the left gure)

The sheets A and B are used for adjusting the height of the top surface of the bed. Use one more

sheet to increase the height, or use only one sheet to decrease it.

Be sure to use a short nail

❺

for sheet B. If long nail

❹

is used, the nail tip can penetrate the table

giving rise to a risk of injury.

❹

25 mm

❺

19 mm

❷

❹

❸

❸

❺

❺

❻

❼

❶

❽

Sheet B

Sheet A

Loading...

Loading...