English 5.906-432.0 Rev. 00 (06/15) 117

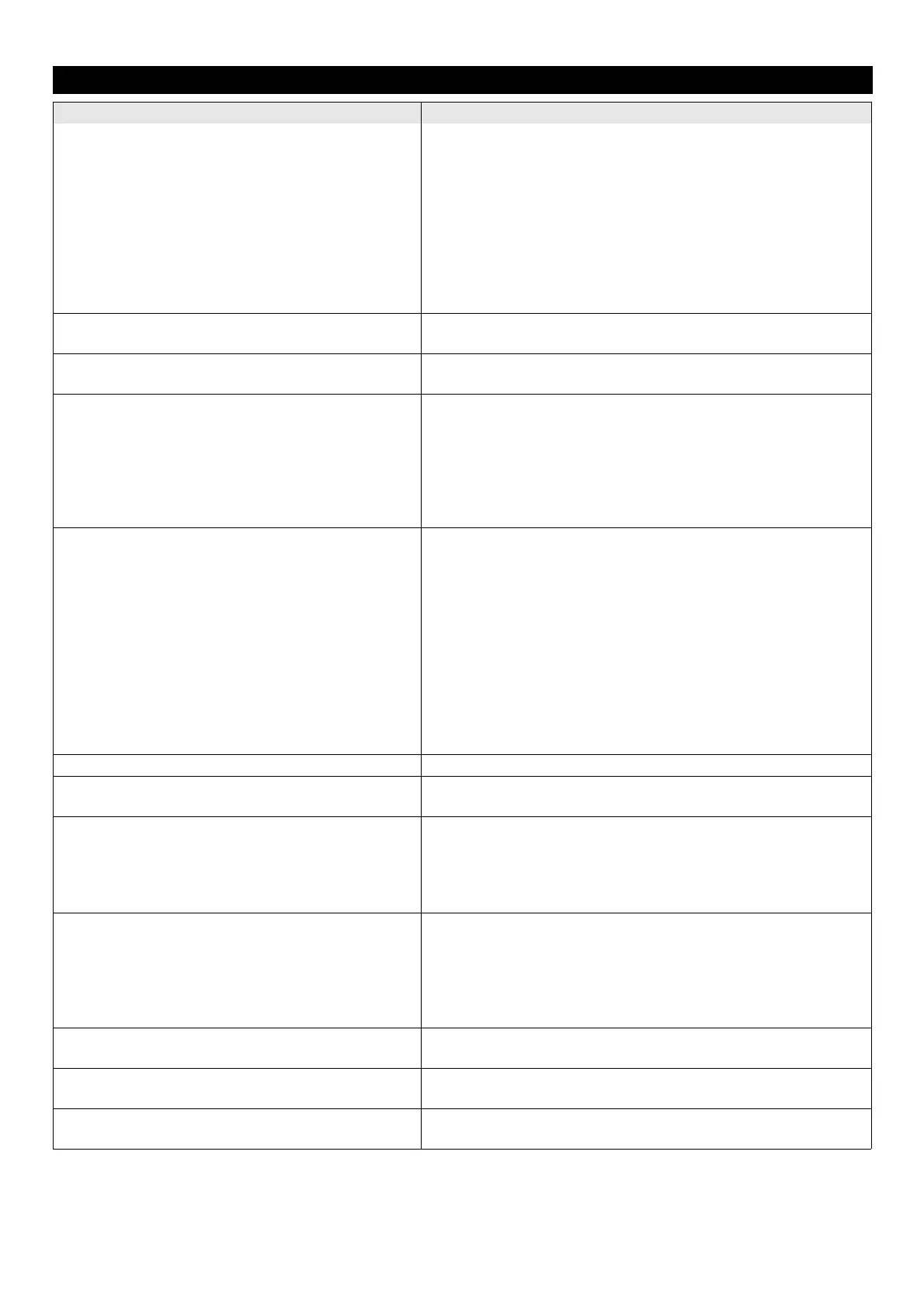

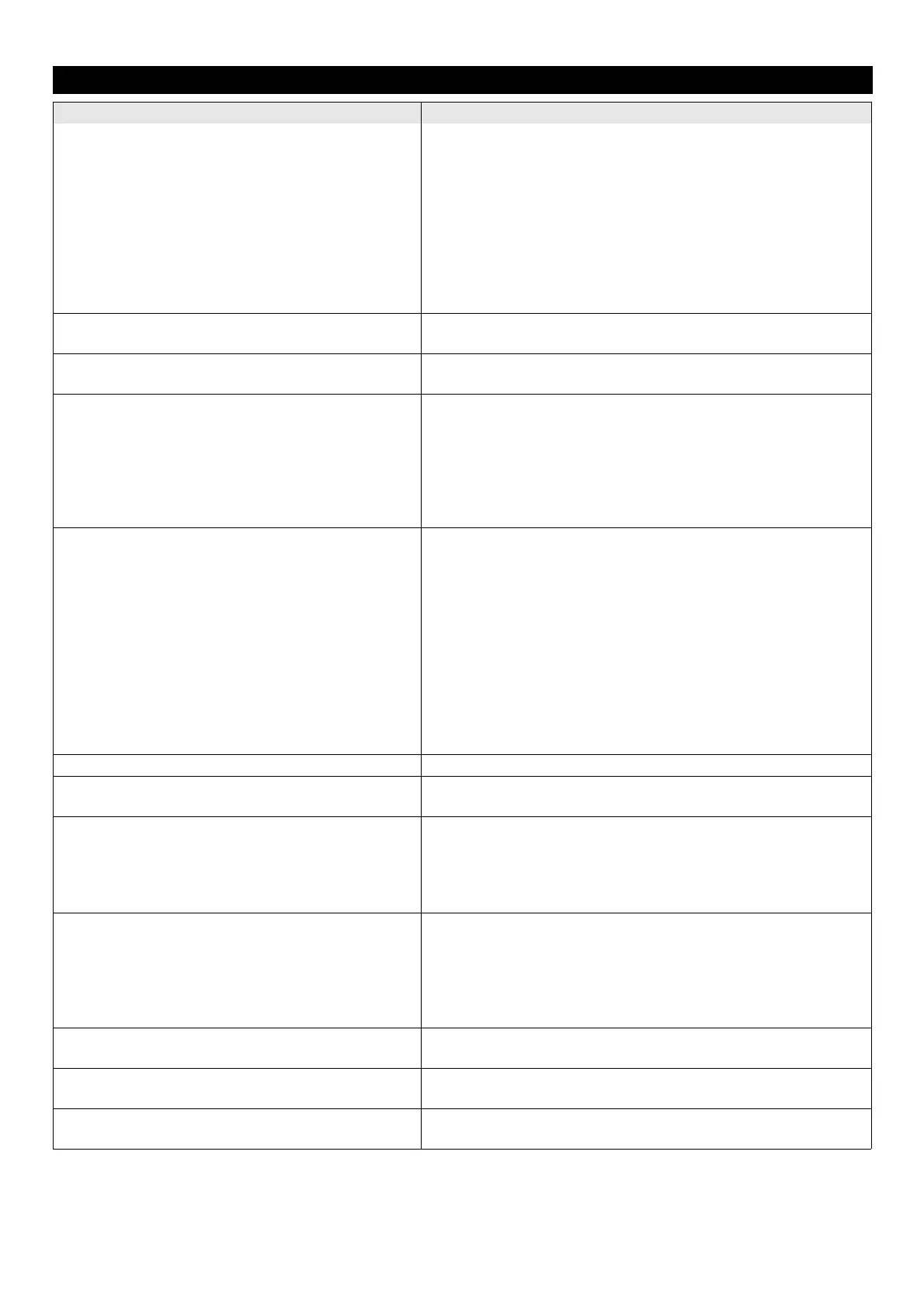

9 Troubleshooting

Failure Measure

Device is not running (no LED/display indication)

– Check/replace mains voltage, connecting cable and mains

fuse.

– Check the fuse (F1).

– Check/replace the power switch.

– Check/replace the pressure switch

– Check/adjust/replace control transformer.

– Check/replace the temperature fuse.

– Check/replace the PCB.

– Unplug the RFID cable from the PCB and switch RFID in the

software.

Device is not running, LED standby is on or the

display shows three filling levels

– Check pressure switch electrically and mechanically.

Winding protection contact was triggered

– Switch off appliance and let it cool down. Remove the cause of

the problem. Turn on the appliance again.

Water pressure too low

– Check/raise the water input amount.

– Check/clean/replace water fine filter.

– Vent appliance.

– Check/replace high-pressure nozzle.

– Check/replace the pressure and suction valves

– Check / adjust/ replace overflow valve.

– Check/adjust/replace safety valve.

Water is not being heated

– Check/correct temperature setting.

– If the water shortage safeguard is switched off, ensure suffi-

cient water supply/repair water shortage safeguard.

– Check/refill fuel level in the tank.

– Check/replace the solenoid valve fuel pump.

– Check/replace fuel filter.

– Check/correct the setting of the fuel pump.

– Check/correct fuel nozzle.

– Check/replace ignition cables.

– Check/correct distances of the ignition electrodes.

– Check/repair burner blower.

– Check/correct setting of the air flap.

Control LED is on

– 5.4.1Control panel with LED indicator

During operation, all 10 LEDs are blinking at the

same time, device switches off

– Check service switch and ribbon cable.

Inadequate or no detergent function

– Check/correct dosing valve setting.

– Check/clean detergent tank.

– Check/clean/replace detergent filter.

– Check/replace detergent hose, dosing valve and detergent in-

let at the cylinder head.

Pressure reduction in the HP system

– Check the trigger gun and the O-rings on the high-pressure

hose for leaks / replace.

– Check the pressure holding valve for leaks/replace the O-

rings.

– Check / adjust/ replace overflow valve.

– Check/replace the pressure switch and control piston.

Water leak between the cylinder head and the pis-

ton casing

– Leakiness of 1 drop per minute and piston is acceptable.

– Check/replace high pressure and low pressure seals.

Oil leaks between the cylinder head and the pis-

ton casing

– Replace the oil seals.

Pump is vibrating

– Check pump for leaks/eliminate leaks.

– Vent appliance.

Loading...

Loading...