6-9

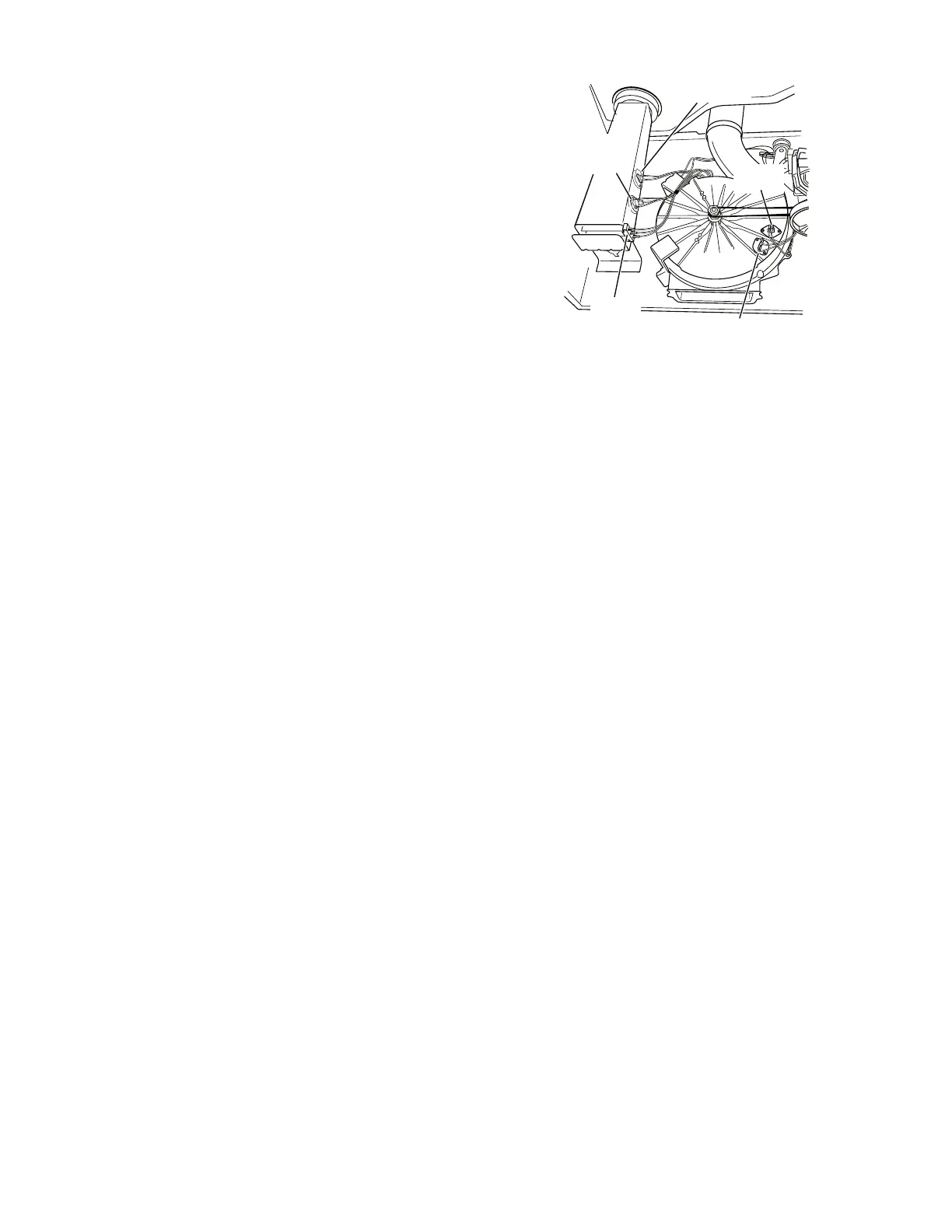

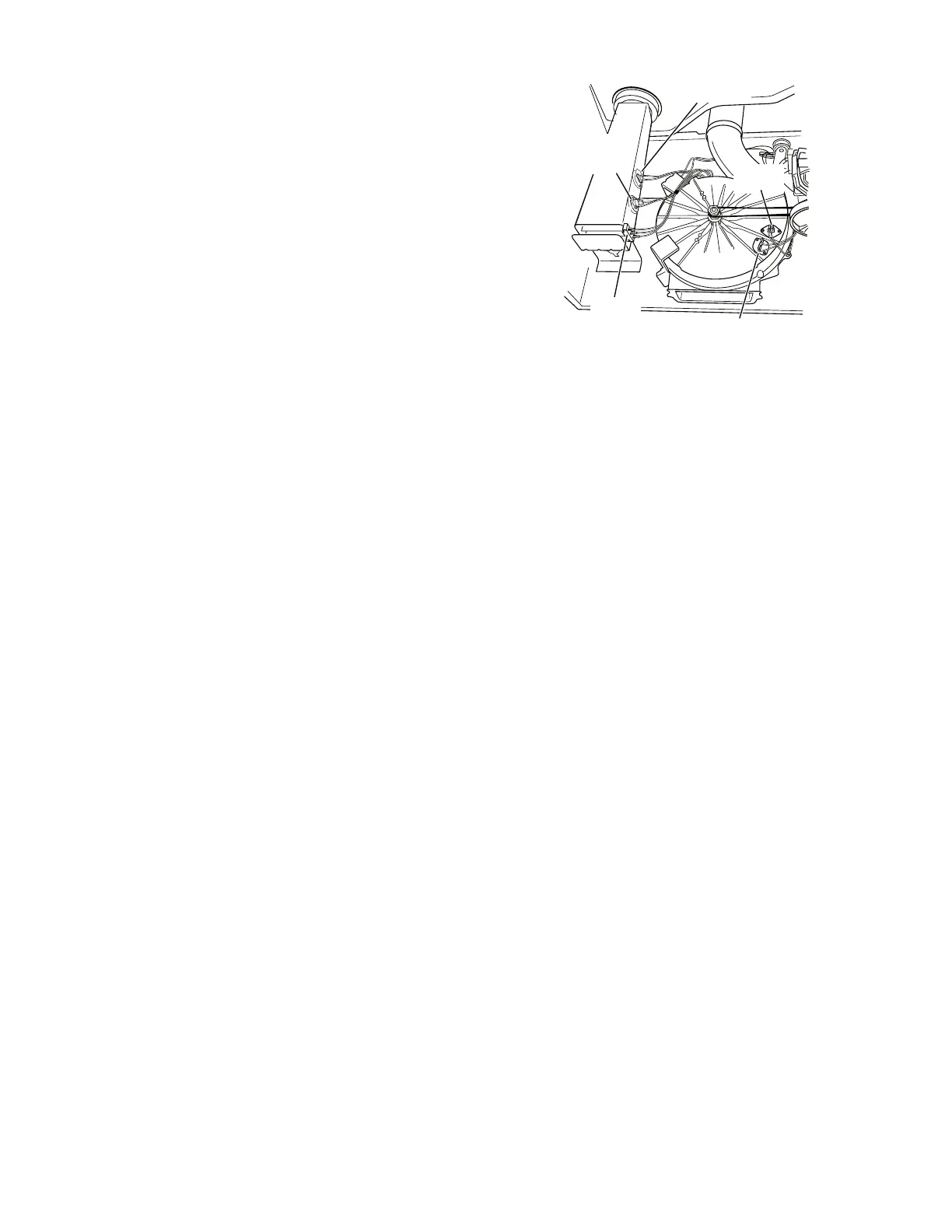

Thermal Fuse

Exhaust

Thermistor

Inlet Thermistor/

High Limit

Thermostat

Thermal Cut-Off

Heater

Element

Figure 10. Thermal components, viewed

from front.

4. Visually check the wire connections to

the thermal cut-off, high limit thermostat,

and heater. If connections look good,

check for continuity across each of these

components.

Replace the heater if it is electrically

open.

Replace both the thermal cut-off and

high limit thermostat if either one is

electrically open.

5. If no open circuit is detected, remove the

P4 connector, then measure the resis-

tance between P4-3 (red wire) and P4-6

(red wire) at the connector. See Figure 16,

for connector location; and Accessing &

Removing the Electronic Assemblies.

If 5–15 k ohms are measured, replace

the machine control electronics.

If the resistance is less than 1 k ohm,

replace the thermistor.

•

•

•

•

TEST #4 Heater

This test is performed when either of the fol-

lowing situations occur:

Dryer does not heat

Heat will not shut off

This test checks the components making up

the heating circuit. The following items are

part of this system:

Harness/connection

Heater relay

Thermal cut-off

Inlet thermistor/high limit thermostat

Heat element assembly

Centrifugal switch

Exhaust thermistor

Machine control electronics. See ESD

information

User interface assembly

Dryer does not heat:

Locate the components using Figure 1 and

Figure 10.

SINGLE ELEMENT MODEL:

1. Unplug dryer or disconnect power.

2. Remove the front panel and drum assem-

bly to access the thermal components.

See Removing the Front Panel/Drum As

-

sembly.

3. Using an ohmmeter and referring to the

appropriate wiring diagram and strip cir

-

cuit (see Section 7), measure the resis

-

tance from the red wire at the thermal

cut-off to the red wire at the heater.

If the resistance is about 10 ohms, go

to step 5.

If an open circuit is detected, go to

step 4.

•

•

•

•

•

•

•

•

•

•

•

•

•

Loading...

Loading...