7 — DIAGNOSTICS AND TROUBLESHOOTING

pg. 207

Return to TOC Curtis AC F2-A, F4-A, F6-A Motor Controllers – FOS 4.5 – April 2022

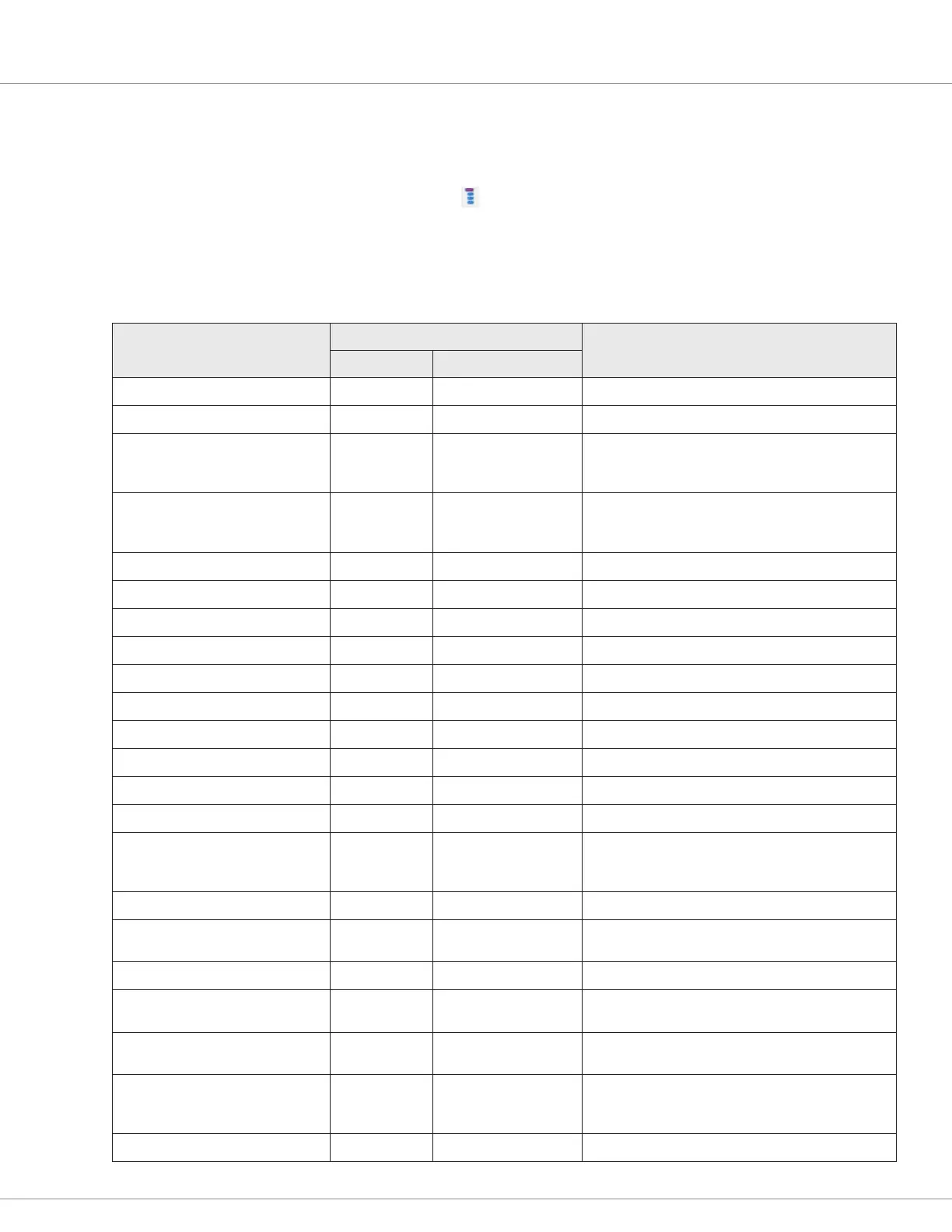

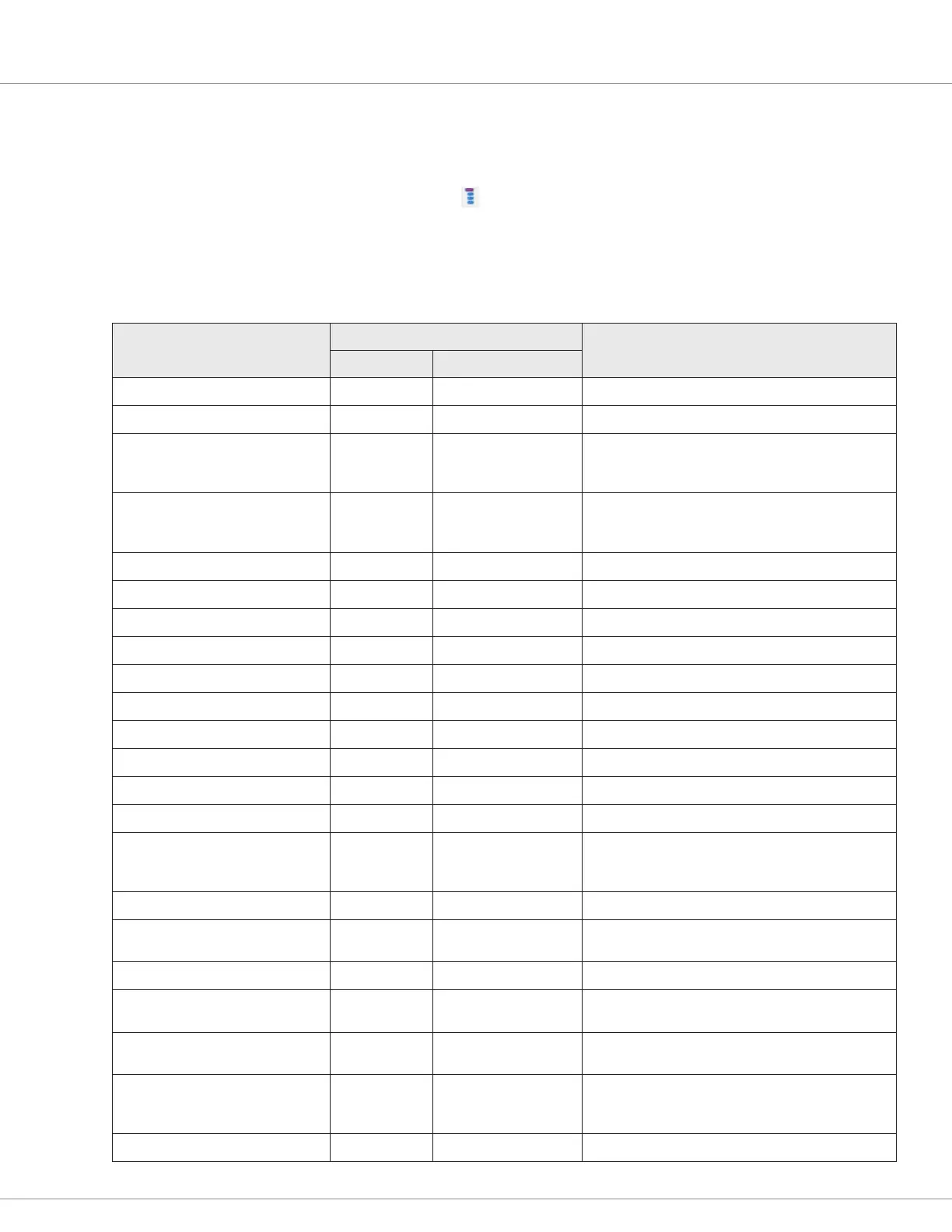

FAULT ACTIONS

e fault actions (eect of fault) in Table 23 use the action code bits individually or when combined as

listed in the fault action column in Table 24. e variable System_Action (0x4E00), which is available

in the CIT Programmer List View ( ), or TACT, returns the decimal number corresponding to the

active fault action bit(s). e example illustrates how to determine and plan for faults in both single

and dual motor applications.

Table 23 Fault Actions

Fault Action

1

Action Code

Description

Hex Bit(s)

NO_ACTION 0x00000000

ShutdownMotor 0x00000001 1 Disables the motor.

ShutdownMainContactor 0x00000002 2

Shut down the Main contactor.

Opens the main by de-energizing the main

contactor driver, only if Main Enable = On.

ShutdownEMBrake 0x00000004 3

Shut down the EM Brake.

Sets the EM Brake by de-energizing the driver, only

if the parameter Set EM Brake On Fault = On.

ShutdownThrottle 0x00000008 4 Set the Throttle_Command = 0%.

ShutdownInterlock 0x00000010 5 Set the Interlock_State = Off.

ShutdownDriver1 0x00000020 6 Shut Down Driver1 (e.g., turn off the driver’s PWM).

ShutdownDriver2 0x00000040 7 Shut Down Driver2 (e.g., turn off the driver’s PWM).

ShutdownDriver3 0x00000080 8 Shut Down Driver3 (e.g., turn off the driver’s PWM).

ShutdownDriver4 0x00000100 9 Shut Down Driver4 (e.g., turn off the driver’s PWM).

ShutdownPD 0x00000200 10 Shut down Proportional Driver (legacy name).

FullBrake 0x00000400 11 Set the Brake_Command = 100%.

ShutdownPump 0x00000800 12 Disables the pump.

TrimDisable 0x00001000 13 Disable Dual Drive trim calculation.

SevereDual 0x00002000 14

For a Dual Drive system, one controller has a severe

fault but the main contactor must stay closed so the

other controller can continue to operate.

ShutdownSteer 0x00004000 15 Steer angle = 0° (Dual Drive applicable).

LOSDual 0x00008000 16

For a Dual Drive system, it uses the max speed set

by the Dual_LOS_Max_Speed parameter.

ShutdownDriver5 0x00010000 17 Shut Down Driver 5 (e.g., turn off the driver’s PWM).

ShutdownDriver6 0x00020000 18

Shut Down Driver 6 (as applicable to the controller;

e.g., turn off the driver’s PWM).

ShutdownDriver7 0x00040000 19

Shut Down Driver 7 (as applicable to the controller;

e.g., turn off the driver’s PWM).

ShutdownCoilSupply 0x00080000 20

Shuts down (turns off) the Coil Supply (return)

voltage. (Note, based upon the controller model, this

will also shut down the low-side drivers).

ShutdownVehicle 0x01000C0F 25, 12, 11, 4, 3, 2, 1 Evokes all Fault Actions as per the indicated bits.

Loading...

Loading...