4 — PROGRAMMABLE PARAMETERS

pg. 55

Return to TOC Curtis AC F2-A, F4-A, F6-A Motor Controllers – FOS 4.5 – April 2022

SPEED MODE/RESPONSE — FINE TUNING MENU

PARAMETER ALLOWABLE RANGE DEFAULT DESCRIPTION

HS (High Speed)

HS

0x3107 0x00

0 – 100 %

0 – 32767

70 % Sets the percentage of the Typical Max Speed above which the

HS parameters will be used.

See Figures 16 and 17 (below).

LS (Low Speed)

LS

0x3109 0x00

0 – 100 %

0 – 32767

30 % Sets the percentage of the Typical Max Speed below which the LS

parameters will be used.

See Figures 16 and 17 (below).

Max Speed Accel

Max_Speed_Accel_SpdM

0x3836 0x00

0.1 – 30.0 s

100 – 30000

1.0 sec In some applications the Max Speed value is changed frequently

through VCL or over CAN (PDOs). The Max Speed Accel parameter

controls the rate at which the maximum speed setpoint is allowed

to change when the value of Max Speed is raised. The rate set

by this parameter is the time to ramp from 0 rpm to Typical Max

Speed rpm.

For example, suppose the Max Speed is raised from 1000 rpm

to 4000 rpm. If the Typical Max Speed is 5000 rpm and the rate

is 10.0 seconds it will take 10.0 * (4000-1000) / 5000 = 6.0

seconds to ramp from 1000 rpm to 4000 rpm.

Max Speed Decel

Max_Speed_Decel_SpdM

0x3837 0x00

0.1 – 30.0 s

100 – 30000

10.0 sec This parameter works like the Max Speed Accel parameter except

that it controls the rate at which the maximum speed setpoint is

allowed to change when the value of Max Speed is lowered.

For example, suppose the Max Speed is decreased from 4500

rpm to 2500 rpm. If the Typical Max Speed is 5000 rpm and the

rate is 5.0 seconds it will take 5.0 * (4500-2500) / 5000 = 2.0

seconds to ramp from 4500 rpm to 2500 rpm.

Reversal Soften

Reversal_Soften

0x310B 0x00

0 – 100 %

0 – 3000

20 % Larger values create a softer reversal from regenerative braking

(regen) to drive when near zero speed. This helps soften the

transition when the regen and drive current limits are set to

different values.

Note: This parameter is not mode-specic.

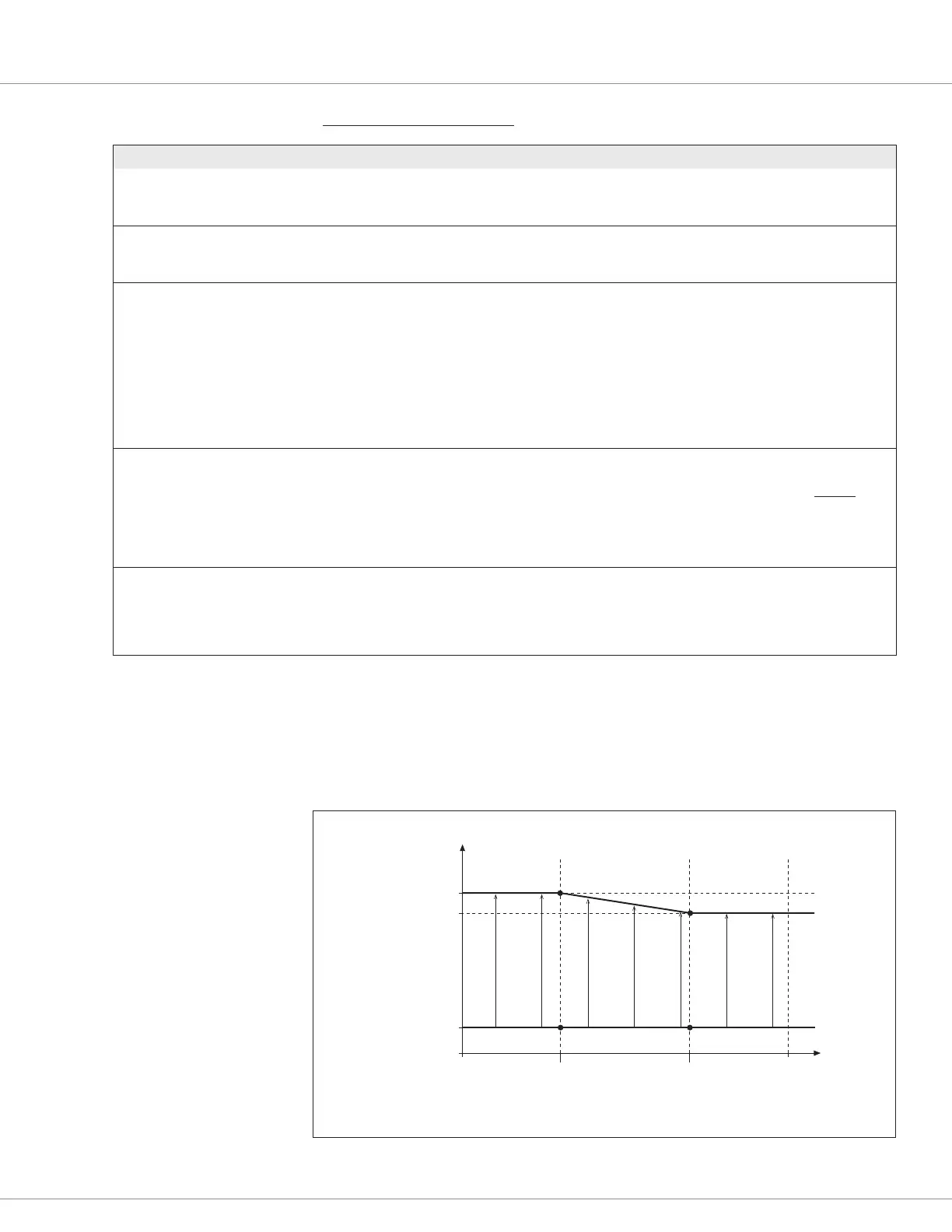

ACCEL RATE

(seconds)

MOTOR SPEED

LOW SPEED

FASTER

Full Accel Rate LS = 1.5

Full Accel Rate HS = 3.0

Low Accel Rate = 20.0

HIGH SPEED

TYPICAL MAX

SPEED

FASTER

90% Throttle

10% Throttle

INCREASING THROTTLE

(LS x Typical_Max_Speed)

= 30% x 5000 rpm = 1500

(HS x Typical_Max_Speed)

= 70% x 5000 rpm = 3500

Figure 16

Acceleration Response

Rate Diagram.

In this example,

HS = 70 %,

LS = 30 %,

Typical Max Speed = 5000 rpm

Loading...

Loading...