148 Section 8 Component Testing and Adjustment TP-6356 4/12

8.20 Speed Sensor

The speed sensor is found on permanent magnet (PM)

and wound field (WF) alternators. The speed sensor is

located on the alternator end bracket. Several styles are

used, but they are all functionally the same.

Follow the procedure outlined below to determine if the

speed sensor (overspeed fault) is emitting a signal.

8.20.1 Speed Sensor Test with Generator

Set Running

1. With the generator set master switch in the

OFF/RESET position, connect a DC voltmeter

between the positive (+) lead (wire 24) at the speed

sensor and the ground (wire 2). The voltmeter

should read approximately 8--12 volts DC.

2. Place the generator set master switch in the RUN

position to start the generator set.

3. With the generator set running, connect a DC

voltmeter negative probe to the 0 terminal

(wire 16—white) on the speed sensor. Place the

voltmeter positive probe on the positive (+) terminal

(wire 24—red). The voltmeter should indicate

approximately 7--12 volts DC.

During the test, the controller leads must remain

connected to the speed sensor terminals. Slide

leads from speed sensor terminals only enough to

expose connection for test leads. Do not

disconnect the leads.

4. Place the generator set master switch in the

OFF/RESET position to stop the generator set.

5. If the speed sensor is emitting a signal, check the

continuity of the speed sensor leads (wires 2, 16,

and 24) between the controller P1 connector and

the lead terminals at the speed sensor.

If the speed sensor is not emitting a signal, go to

Section 8.20.2, Speed Sensor Test with Separate

12 VDC Source.

8.20.2 Speed Sensor Test with Separate

12 VDC Source

Test the speed sensor using the following procedure. It

is NOT necessary to remove the speed sensor from the

end bracket.

1. Place the generator set master switch in the

OFF/RESET position.

2. Disconnect the speed sensor leads.

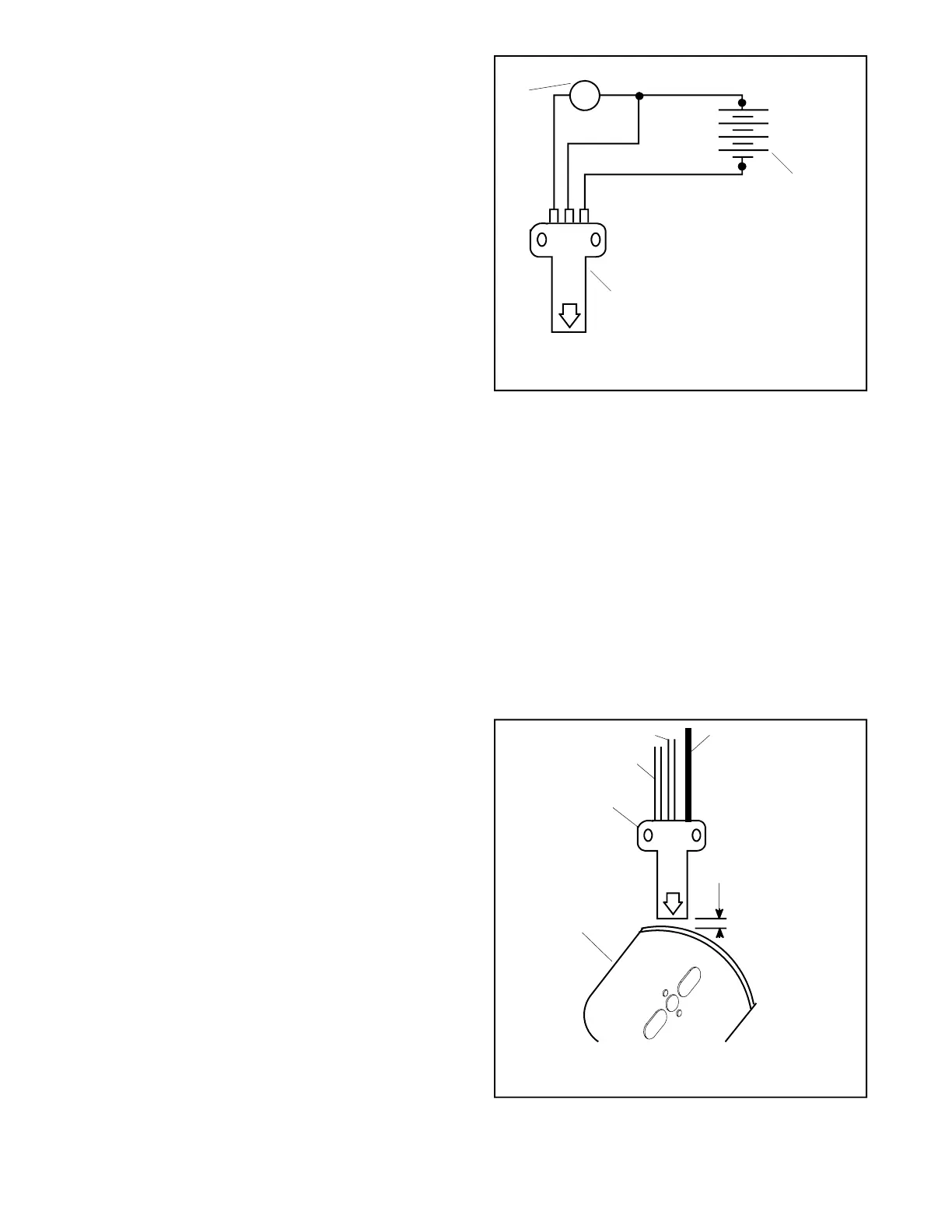

3. Connect speed sensor, DC voltmeter, and DC

voltage source as shown in Figure 8-46.

+

---

+

1

2

3

TP-5353-7

1. DC voltmeter

2. 12-volt battery or DC power supply

o + ---

3. Sensing surface

Figure 8-46 Speed Sensor Test

4. Touch sensing surface with a flat piece of iron or

steel at least 4.1 cm (1/4 cu. in.) in size.

5. The DC voltmeter test reading should equal the

source voltage, approximately 12 VDC.

6. Remove the iron or steel piece from the sensing

surface and observe a voltmeter reading of 0 VDC.

7. If the speed sensor passes steps 5 and 6, the

speed sensor is functional. Replace the speed

sensor if it fails the test.

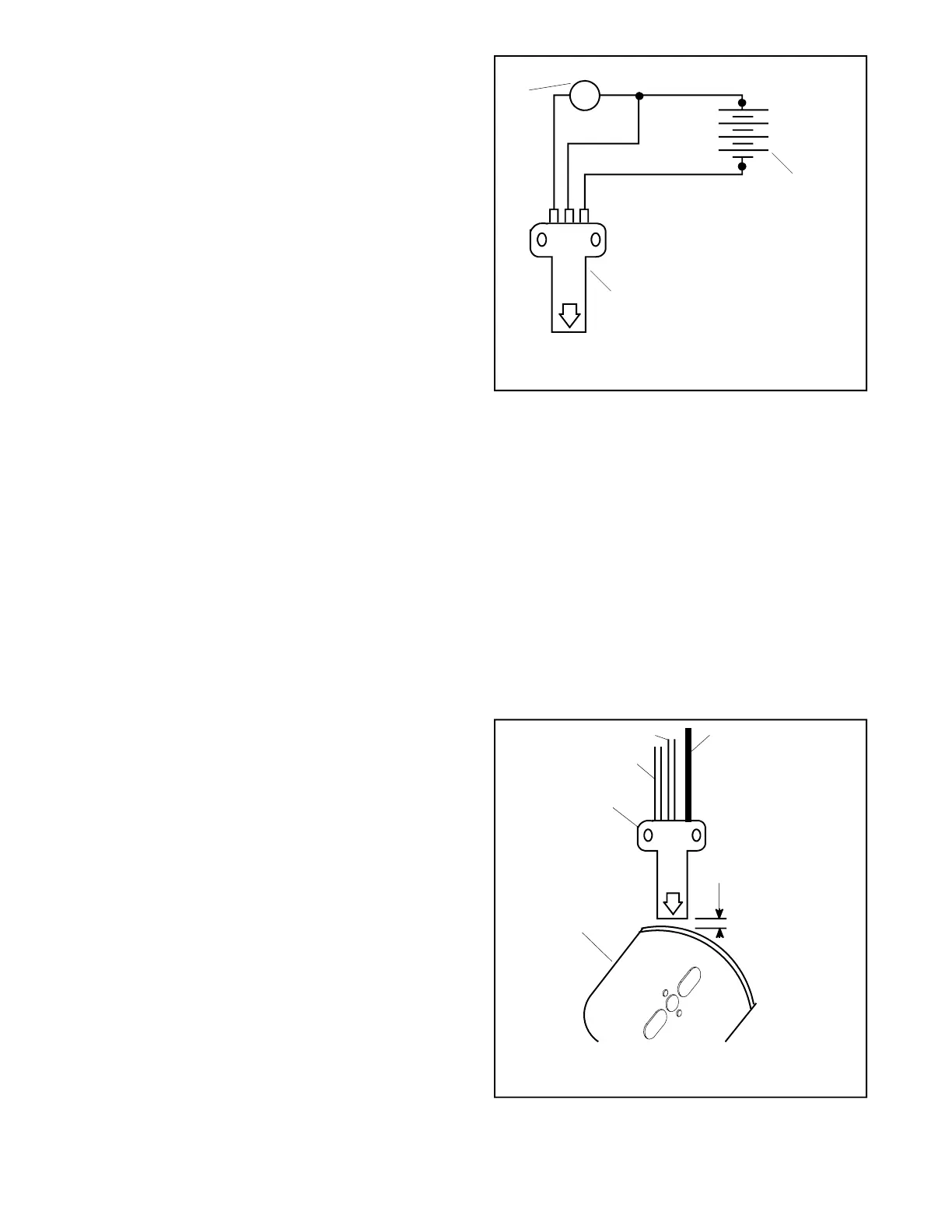

8. Connect the speed sensor leads and adjust the air

gap. See Figure 8-47.

4. Wire 2: black

5. Air gap

6. Magnetic actuator

0.36--0.71 mm

(0.014--0.028 in.)

TP-5353-8

1. Speed sensor

2. Wire 16: white/clear

3. Wire 24: red

1

2

3

4

5

6

o+--

Figure 8-47 Speed Sensor Air Gap

Loading...

Loading...