193Section 10 Governor AdjustmentsTP-6356 4/12

3. Slowly back out the high idle screw while holding

the engine speed lever in the high idle position until

you obtain the desired frequency.

4. Tighten high idle locknut to 4--5 Nm (35--45 in. lb.).

5. Turn in the low idle screw to lock lever in place and

tighten low idle locknut to 4--5 Nm (35--45 in. lb.).

6. Readjust the frequency with the INC/DEC buttons

on governor controller to bring the frequency to

67 Hz for 60 Hz models and 56 Hz for 50 Hz

models.

7. With no load applied, increase the overall gain until

the engine begins to hunt.

If the engine does not begin to hunt, momentarily

disrupt the governor power supply. Then decrease

the overall gain until stable.

For optimum performance, the engine should

oscillate 3--5 diminishing cycles after being

disrupted.

Troubleshooting

If the governor system fails to operate and the actuator is

suspected to be the problem, perform the following

tests.

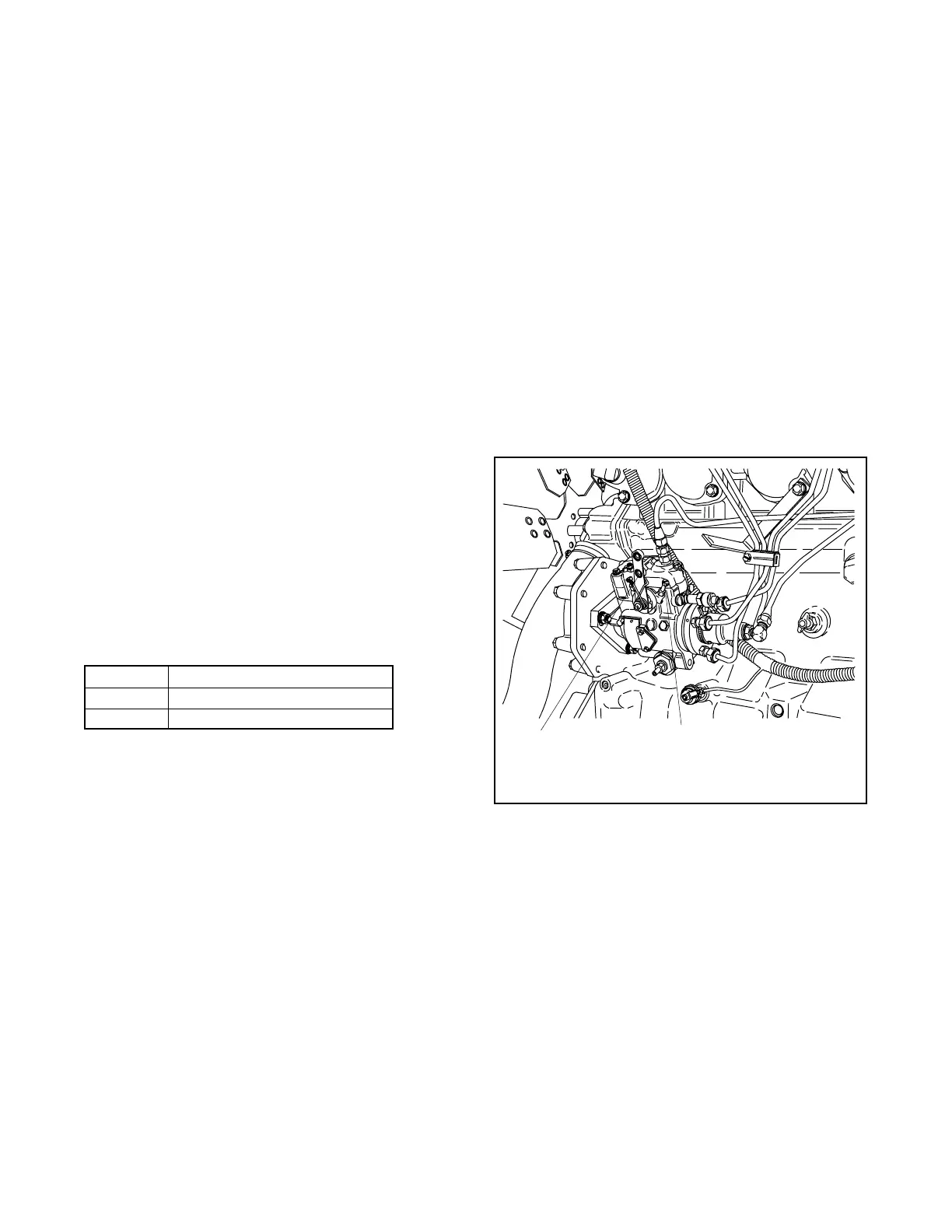

Measure the actuator coil resistance. The values shown

in Figure 10-7 are for readings at ambient temperature.

Actuator Resistance, ohms

12 VDC 2.05 ±0.25

24 VDC 7.20 ±0.50

Figure 10-7 Actuator Coil Resistance Values

Measure the coil isolation. The coil to case resistance

should be >3 megohms.

Remove the actuator from the generator set. Manually

move the actuator through its range of motion. No

binding or sticking should occur.

Before testing the actuator, place a diode (Motorola P/N

MUR810 or equivalent) across the actuator terminals.

Energize the actuator to full fuel position. The actuator

should operate smoothly throughout its entire stroke

without any interruptions in motion.

If the actuator passes these tests, the problem is likely in

the governor controller and/or fuel system.

10.3 Mechanical Governor

10.3.1 Stanadyne DB2/DB4

Note: Before checking and adjusting engine speed,

make sure engine has reached its normal

operating temperature.

All speeds indicated apply to a hot engine under load.

The maximum permissible speed variation is 50 rpm for

fast idle speed.

1. Disconnect speed control from fuel injection pump

lever.

2. Move the generator set master switch to the RUN

position to start the generator set.

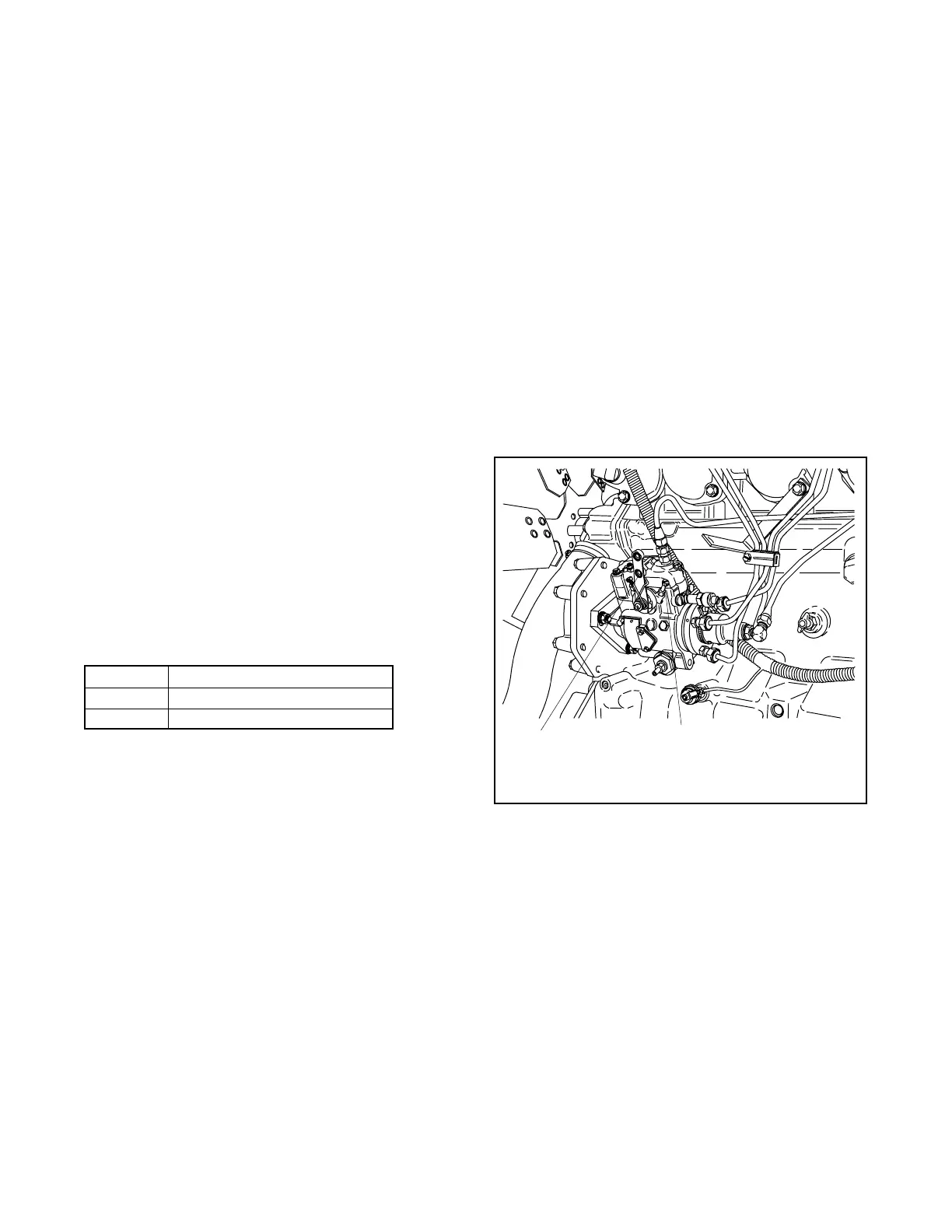

3. Verify that injector pump lever is held in fast idle

position against fast idle adjusting screw. See

Figure 10-8.

TP-5353-7

12

1. Injection Pump Lever

2. Fast Idle Adjusting Screw

Figure 10-8 Governor Adjustments, Typical

4. Using a tachometer, check engine speed. Adjust

engine speed to obtain a full load engine speed of

1800 rpm (60 Hz) or 1500 rpm (50 Hz).

To increase engine speed, rotate fast idle adjusting

screw CCW; rotate fast idle adjusting screw CW to

decrease engine speed.

5. Reconnect speed control to fuel injection pump

lever.

6. Move the generator set master switch to the OFF/

RESET position to stop the generator set.

Loading...

Loading...