58 Section 3 Decision-Makerr 3+ Troubleshooting TP-6356 4/12

3.6.3 FASTCHECKr Diagnostic Tool

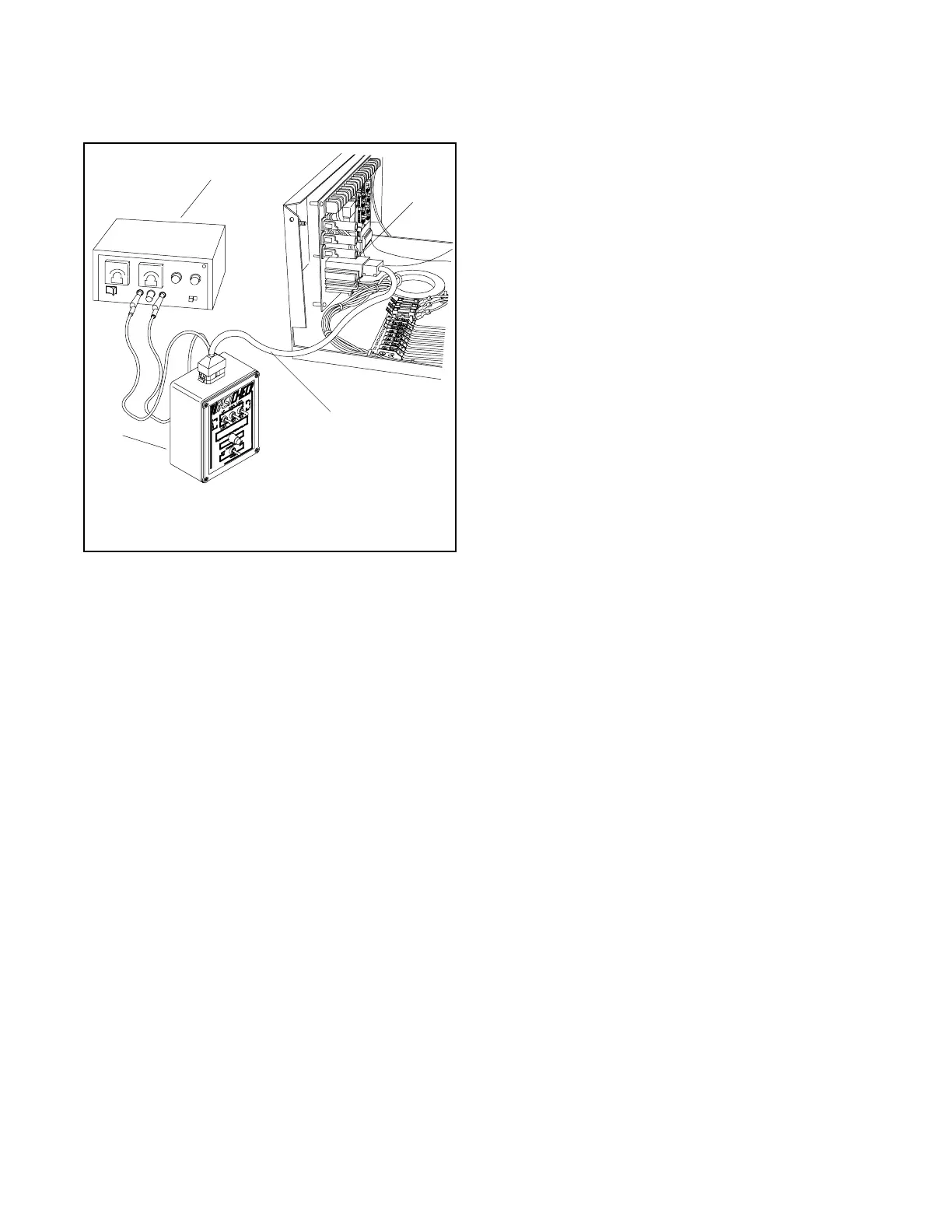

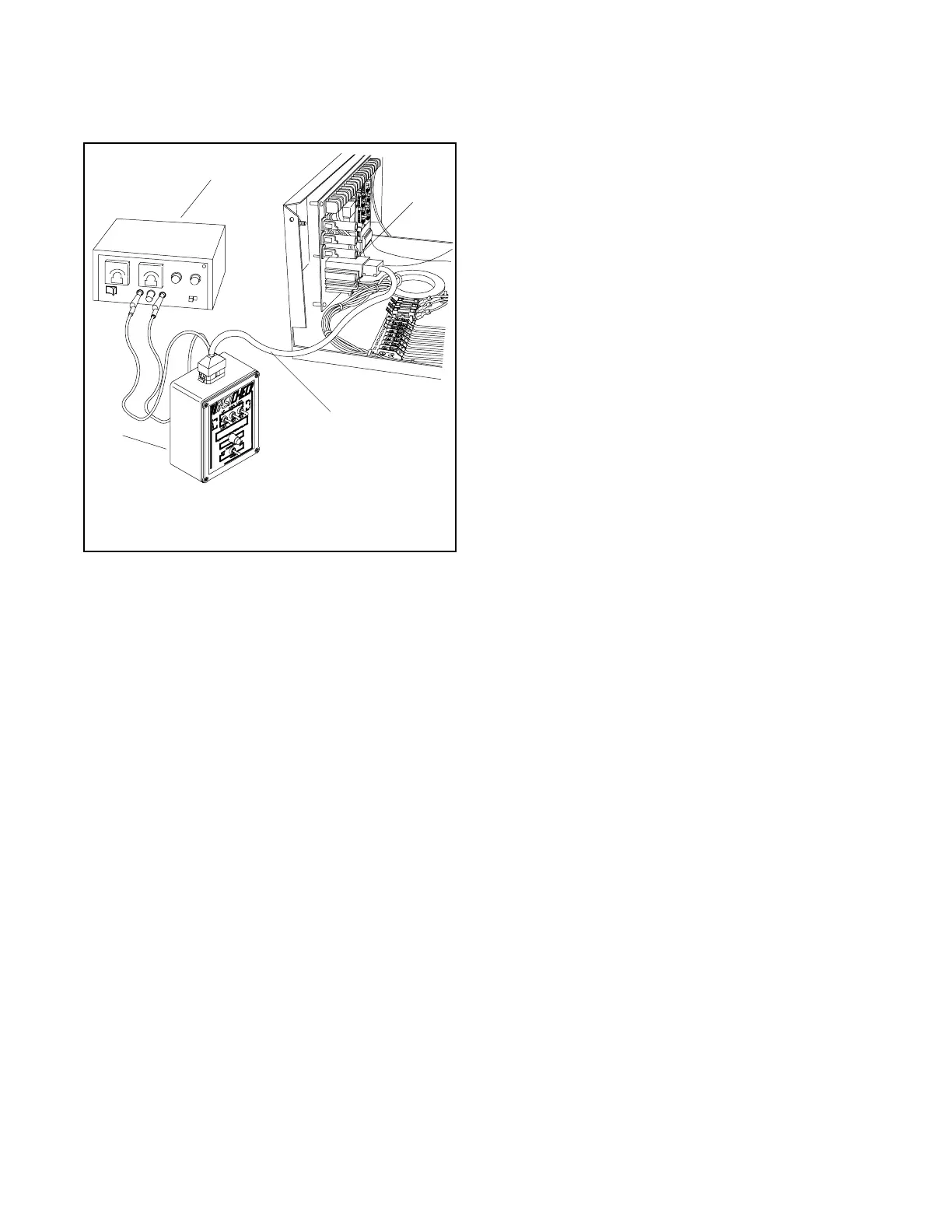

1. Unplug the DC engine harness from the DC

harness connector (P1). See Figure 3-25.

R11118-2

3-187

1. FASTCHECK® diagnostic tool

2. Wiring harness

1

2

3

4

3. DC harness connector

4. DC power supply

Figure 3-25 FASTCHECK

®

Connections

2. Connect the FASTCHECK

®

harness to the DC

harness connector (P1) and to the top of the

FASTCHECK

®

.

3. Move the generator set master switch to the

OFF/RESET position.

4. Move the FASTCHECK

®

engine switch to the OFF

position.

5. Clip the red (+) and black (--) harness leads to a

battery(ies) or DC power supply that corresponds

to the generator set engine electrical system (12 or

24 volt). Adjust the output voltage to 1-2 volts

above the battery voltage when using a DC power

supply. Use generator set battery(ies) if accessible

and fully charged.

Note: Incorrect battery polarity may cause

controller circuit board damage when

connecting the FASTCHECK

®

.

Note: Because of the absence of AC output, the

auxiliary lamp flashes during controller

testing. The NOT IN AUTO lamp illuminates

whenever the generator set master switch is

not in the AUTO position.

6. Move the generator set master switch to the RUN

position. Move the FASTCHECK

®

engine switch

to CRANK. The FASTCHECK

®

IGN., CRK., and

REG. lamps should light. The generator set

controller causes the engine to crank until the

FASTCHECK

®

switch is moved to RUN (or

OVERCRANK shutdown appears on generator set

controller).

7. Move the FASTCHECK

®

engine switch to RUN.

The CRK. lamp should go out and the REG. and

IGN. lamps should stay on.

8. Simulate engine malfunctions by pressing the

FASTCHECK

®

fault switches. The corresponding

fault lamp on the controller should light during each

simulated engine malfunction.

Leave the FASTCHECK

®

engine switch in the

RUN position for at least 30 seconds before

pushing the toggle switches. Toggle the generator

set master switch to OFF/RESET and the

FASTCHECK

®

engine switch to OFF, then back to

RUN after simulated fault shutdowns.

9. Use the following sections to test overcrank

circuitry, speed sensor circuitry, and generator set

condition indicators.

3.6.4 Overcrank

The following procedure tests the overcrank function on

the generator set controller and the ability to:

D Detect a locked engine.

D Stop a startup attempt if the starter locks or will not

engage.

If the OVERCRANK shutdown fails to function, check

the speed sensor and related circuitry. See

Section 3.6.5, Controller Speed Sensor Circuitry, and

Section 8.20, Speed Sensor Test.

1. Move the FASTCHECK

®

engine switch to the OFF

position.

2. Move the generator set master switch to the OFF

position and then move the switch to the RUN

position.

3. The IGN., CRK., and REG. lamps on the

FASTCHECK

®

should light for approximately

5 seconds and then go out. Then 5 seconds later

the IGN., CRK.,and REG. lamps should relight for

5 seconds before going out again (15 seconds total

elapsed time). The controller OVERCRANK lamp

lights.

4. Check for operating voltage between terminals

TB1-42A (+) and TB1-12 (--).

Loading...

Loading...