163Section 9 Gas Fuel SystemsTP-6356 4/12

Section 9 Gas Fuel Systems

This section describes various gas fuel systems and

contains troubleshooting information. Fuel system

information provided in this section relates to fuel

configurations not addressed in the engine operation

manual and/or engine service manual.

9.1 Gas Fuel Systems (REZG_ and

REZX_/RZX_ models)

This section describes natural gas and liquified

petroleum gas (LPG) fuel systems that are not covered

in the engine operation manual or engine service

manual.

9.1.1 Gas Fuel System Concept

(Single Fuel)

The gas fuel system uses a fuel solenoid valve to control

the fuel flow to the electronic-controlled pressure

regulator (EPR). The generator set-mounted EPR

reduces the fuel pressure as fuel passes to the fuel

mixer. SeeFigure9-1.

The fuel mixer controls the ratio of fuel to air under

varying load and speed conditions. Because the fuel

mixer receives fuel in a gaseous state, it does not have

to vaporize the fuel.

9.1.2 LPG Liquid Withdrawal Fuel

System Concept

With the LPG liquid withdrawal fuel system, pressurized

liquid LPG fuel passes from the tank to a vaporizer. The

vaporizer converts the liquid fuel to gas before sending it

to the fuel EPR. The system also includes a fuel

solenoid valve that shuts off the fuel flow when the

engine stops. Contact an authorized service

distributor/dealer for availability.

9.1.3 Natural Gas and LPG Conversion

Most models operate on either natural gas or LPG fuel

by performing the fuel conversion procedure. A hang

tag on the fuel regulator may provide additional

conversion setup information. Fuel conversion may

decrease generator set output. Refer to the respective

generator set spec sheet for ratings based on fuel

selection. Changing fuel does not alter the emissions

compliance of the generator set engine. Consult your

local generator set distributor/dealer for additional

information.

SB-700

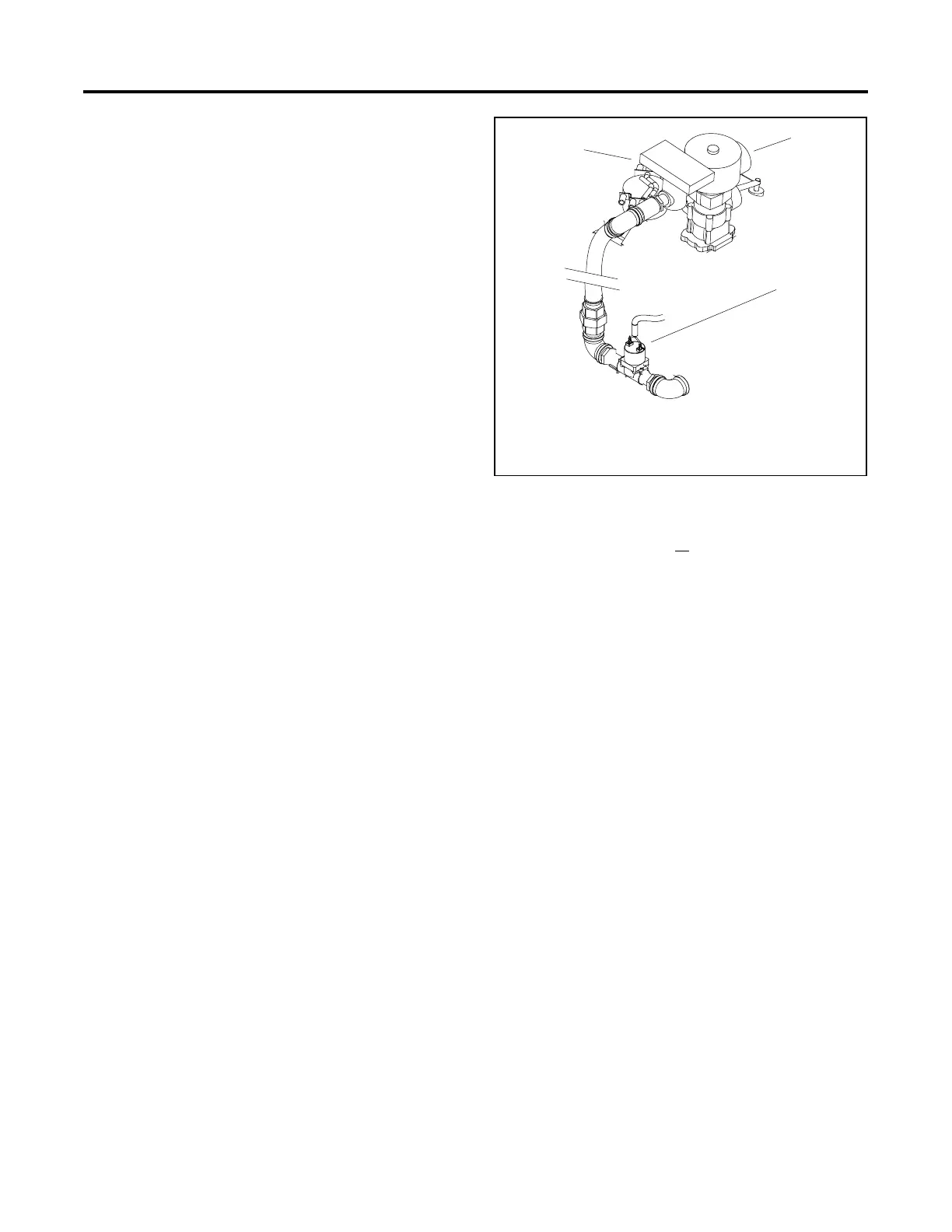

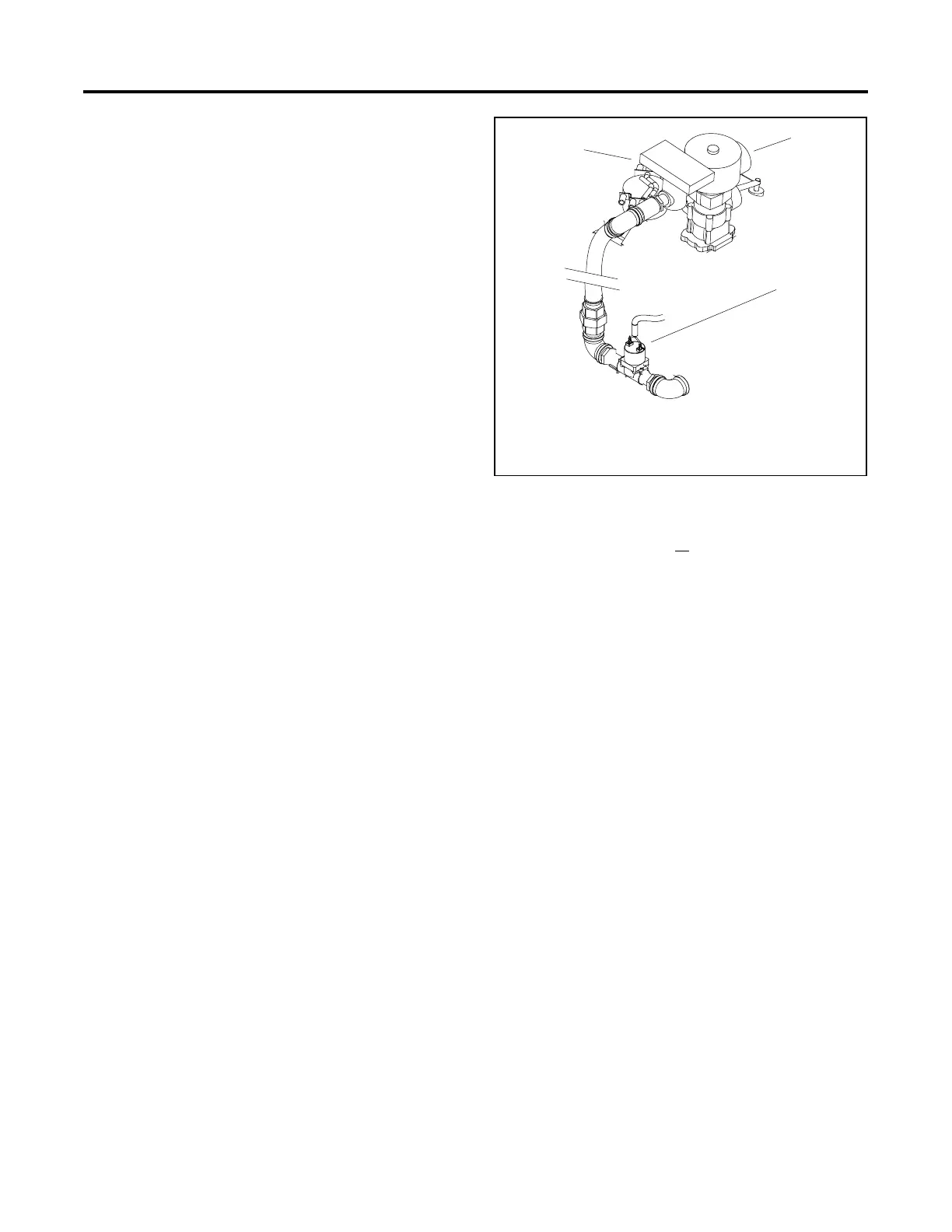

1. Electronic-controlled pressure regulator (EPR)

2. Fuel mixer

3. Fuel solenoid valve

(UL--listed models require 2 fuel solenoid valves)

1

2

3

Figure 9-1 Fuel Regulator and Valve, Typical

Note: If a gas-fueled model has the fuel type changed

(LPG to natural gas or

natural gas to LPG), order

a new nameplate from an authorized distributor/

dealer with the updated ratings and attach to the

generator set.

To change the fuel type, change the electrical

connections between the fuel system and the engine

ECM. The engine ECM has fuel tables and spark

advance curves programmed for both natural gas and

LPG. The information shown below, in Figure 9-2, and

in Figure 9-3 generally apply to all models and all fuels.

Be sure to review the respective wiring diagram for your

specific model for possible special applications.

Natural Gas Operation

D Disconnect lead 65 from lead N5.

D Disconnect lead 73B from the fuel solenoid valve.

D Connect lead 73A to the fuel solenoid valve.

LPG Vapor Operation

D Disconnect lead 73A from the fuel solenoid valve.

D Connect lead 73B to the fuel solenoid valve (LPG

vapor).

D Connect lead 65 to lead N5 (ground).

LPG Liquid Withdrawal Operation

D Disconnect lead 73A from the fuel solenoid valve.

D Connect lead 73B to the fuel solenoid valve (LPG

liquid withdrawal).

D Connect lead 65 to lead N5 (ground).

Loading...

Loading...