176 Section 9 Gas Fuel Systems TP-6356 4/12

5. Change the engine ignition timing (30--60 kW

models only).

a. Loosen the distributor hold-down clamp screw.

b. Remove dirt and grease from the crankshaft

pulley groove and engine timing plate mark

using a clean rag. Highlight the timing marks

with chalk.

c. Connect an ignition timing light to the engine.

Follow the ignition timing light manufacturer’s

instructions.

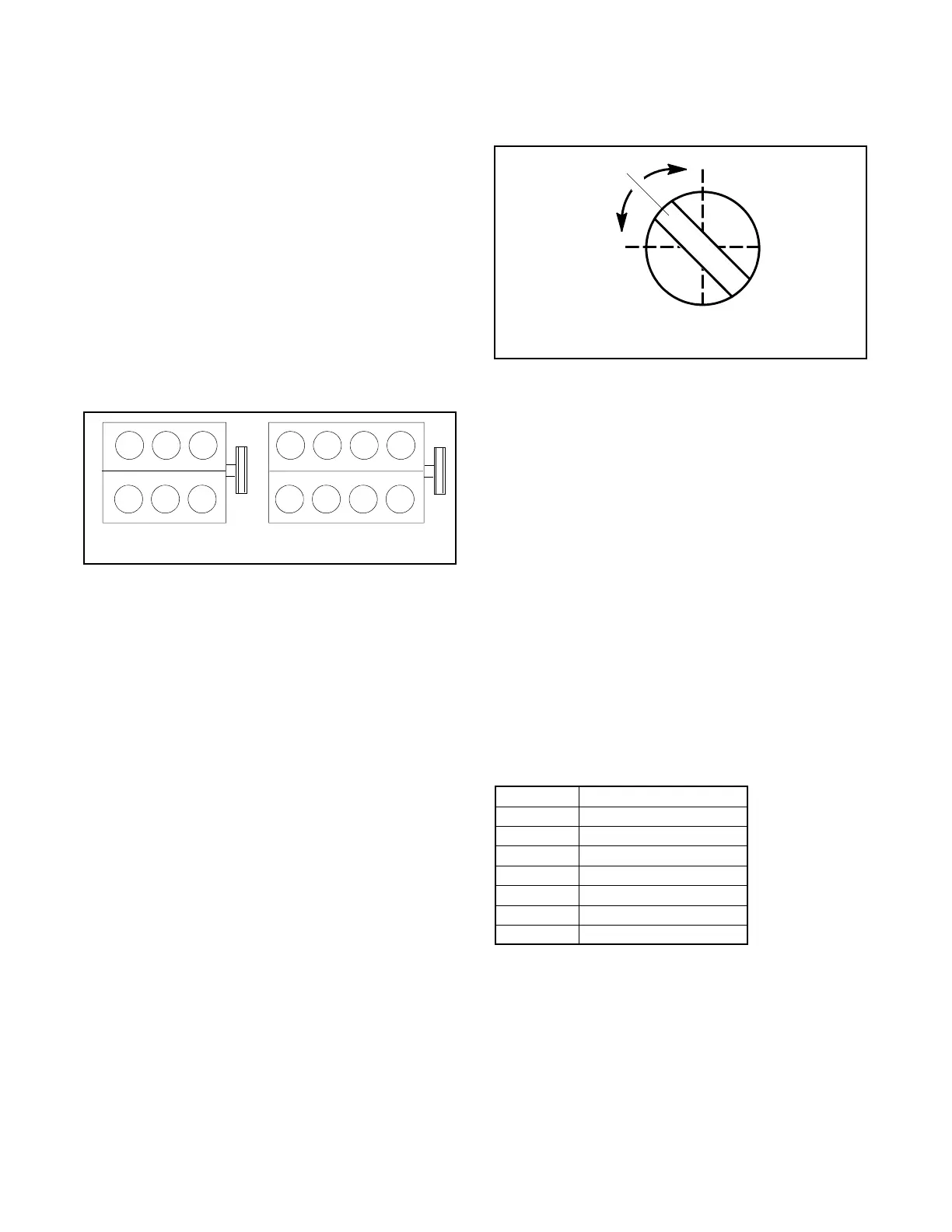

Typically the ignition timing light connects to the

starting battery for power and the inductive

pickup goes on the no. 1 spark plug wire. The

no. 1 spark plug is in the front left side of the

engine. See Figure 9-26.

TT-1295

11

30--45 kW 50/60 kW

Figure 9-26 Engine No. 1 Cylinder/Spark Plug

d. Set the ignition timing light adjustment to

28° BTDC (before top dead center) for LP gas

vapor.

e. Place the generator set master switch in the

RUN position to start the generator set.

f. Point the ignition timing light at the engine

timing plate mark and slowly turn the distributor

CW or counterclockwise (CCW) until the

crankshaft pulley groove aligns with the engine

timing plate mark.

g. Place the generator set master switch in the

OFF position to stop the generator set.

h. Tighten the distributor hold-down clamp to

25 Nm (18 ft. lb.) being careful not to alter the

distributor position.

i. Disconnect the ignition timing light from the

engine.

6. Adjust the gas mixer.

a. Place the generator set master switch in the

RUN position to start the generator set. Run

the generator set at approximately half load.

b. See Figure 9-22 for location of the fuel mixture

adjustment screw and adjust the fuel mixture

screw (Figure 9-27) until the engine runs

smoothly.

1

2

3

TP-5750-3

1. Fuel adjusting screw

2. Lean

3. Rich

Figure 9-27 Fuel Mixture Adjustment, Typical

c. Apply varying loads and readjust the mixer as

necessary to achieve s mooth engine

performance at all load levels.

d. Place the generator set master switch in the

OFF position to stop the generator set.

9.10 Fuel Mixture Adjustment with

Oxygen Sensor A-345052

(30--100 kW GM-Powered Models with

Barber-Colman Governor)

Adapted from Service Bulletin SB-615.

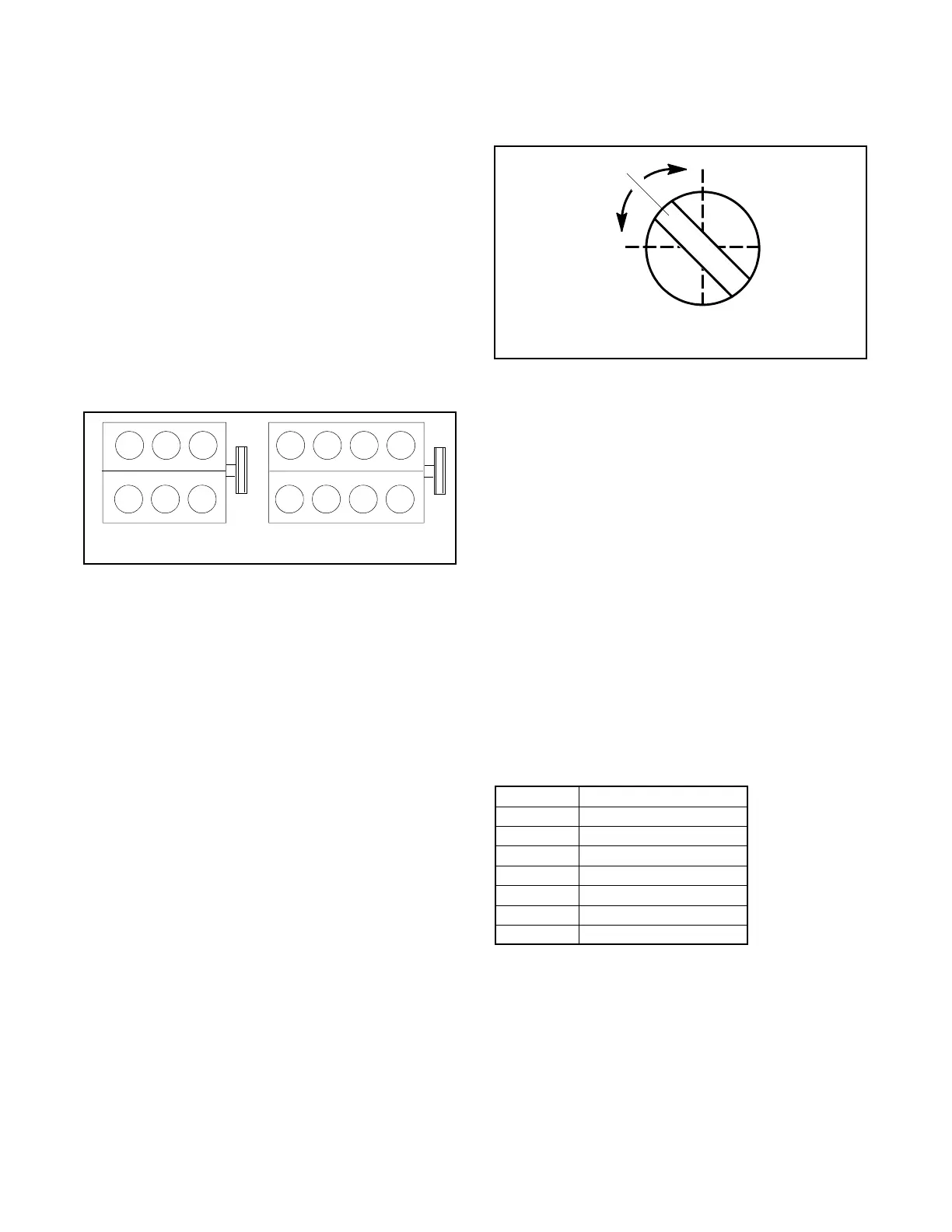

This section details fuel mixture adjustment for General

Motors engine-powered generator sets with Barber-

Colman governors. Figure 9-28 lists specification

numbers for generator sets with Barber-Colman

governors.

Model, kW Spec No.

30 GM13685-GA1, 4, 7, 10

35 GM13685-GA2, 5, 8, 11

45 GM13685-GA3, 6, 9, 12

50 GM13686-GA1, 3, 5, 7

60 GM13686-GA2, 4, 6, 8

80 GM13934-GA1, 2, 3, 4

100 GM13934-GA5, 6, 7, 8

Figure 9-28 Specification Numbers

Use the following procedure to field adjust the fuel

mixture on generator sets that are not California Air

Resources Board (CARB) or United States

Environmental Protection Agency (EPA) certified.

Correct fuel metering valve adjustment provides both

reliable c old starting and overall generator set

performance.

Loading...

Loading...