166 Section 9 Gas Fuel Systems TP-6356 4/12

9.2 Fuel System Concepts

(Pre-REZG_ and REZX_/RZX_

models)

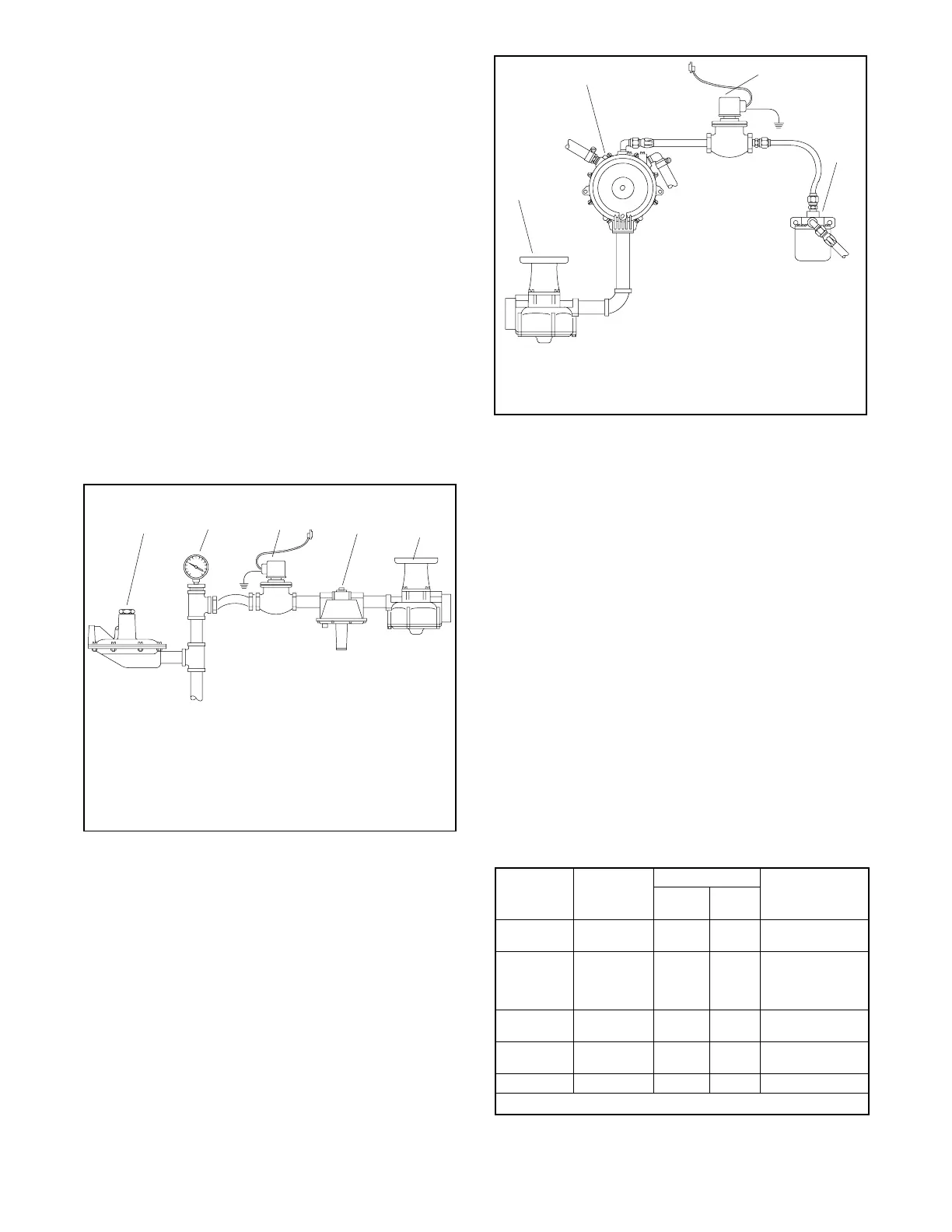

9.2.1 Gas Fuel System Concept

The gas fuel system utilizes a fuel valve with solenoid to

control the fuel flow to the fuel regulator. The

generator-mounted regulator reduces fuel pressure as

fuel passes to the gas mixer. See Figure 9-5. The gas

mixer controls the ratio of fuel to air under varying load

and speed conditions. Because the gas mixer receives

fuel in a gaseous state, it does not have to perform fuel

vaporization. When switching from natural gas to LP

gas or LP gas to natural gas, VERIFY THAT ENGINE

SPEED MEETS SPECIFICATIONS. The governor

should compensate for different types of fuel and

maintain rated engine speed. See Section 9.5,

Carburetor/Gas Mixer Adjustment, for fuel adjustment

when changing fuel type. If engine speed is incorrect,

refer to the governor information to make adjustments.

1 2 3 4 5

TP-5750-3

1. Primary regulator (supplied by gas supplier or customer)

2. Pressure gauge

3. Solenoid valve

4. Secondary regulator

(shown inverted, position varies by model)

5. Gas mixer

Figure 9-5 Fuel Regulator and Valve, Typical

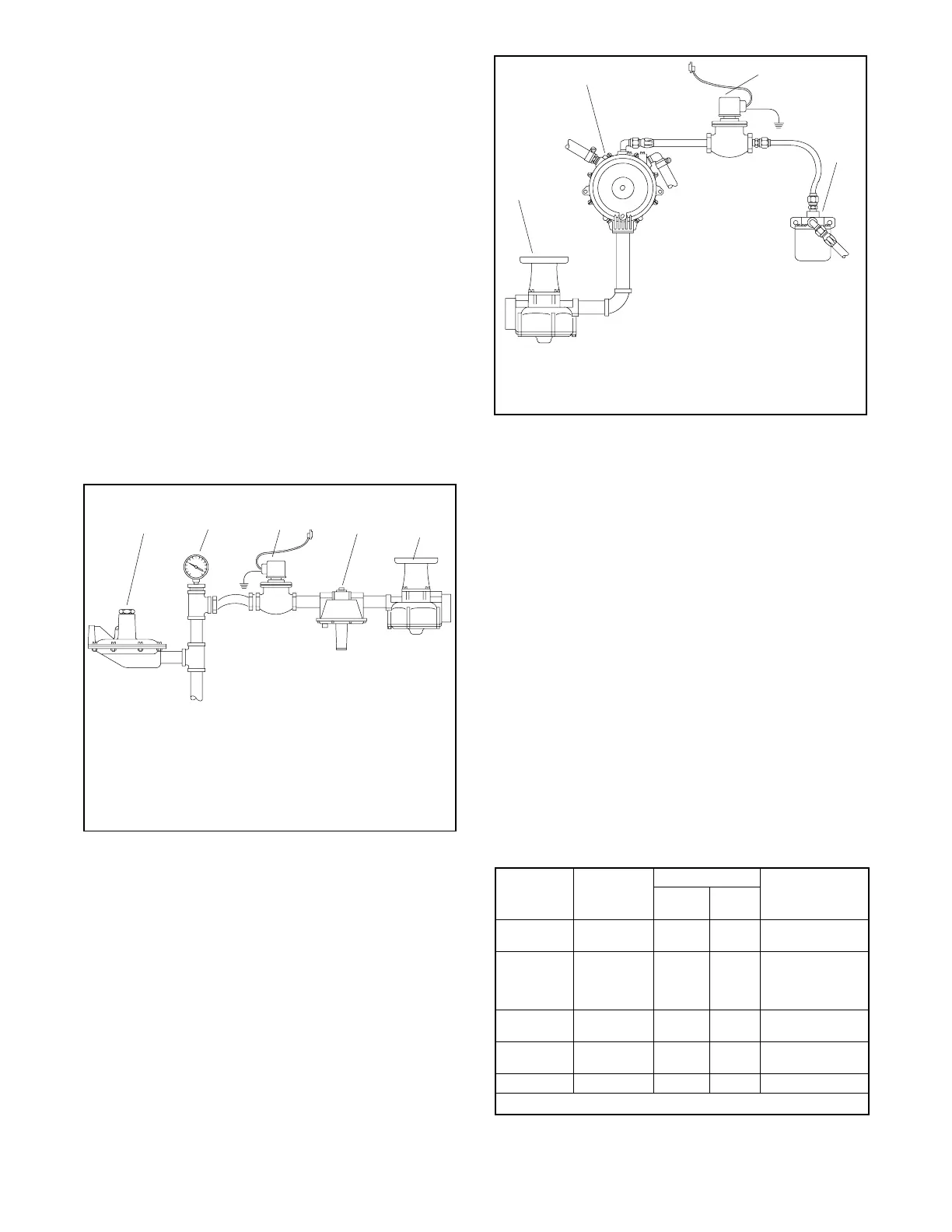

9.2.2 LP Liquid Withdrawal Fuel System

Concept

With the LP liquid withdrawal fuel system, the tank

directs liquid LP fuel under high pressure to a vaporizer.

The vaporizer converts the liquid fuel to a gaseous state

before sending it to the gas mixer. The system also

includes a fuel valve which shuts off the fuel flow when

the engine stops. See Figure 9-6.

1

2

3

4

TP-5700-6

1. Gas mixer

2. Converter (vaporizer)

3. Solenoid valve

4. LP gas filter (supplied by gas supplier or customer)

Figure 9-6 LP Liquid Withdrawal System, Typical

9.3 LP Gas/Natural Gas

Conversion

9.3.1 Straight Gas Fuel System

Most models operate on either LP gas or natural gas fuel

by performing the fuel conversion procedure. Some

models require a different fuel kit when changing gas

fuels.

Fuel conversion may decrease generator set output and

affect exhaust emissions. Refer to the generator set

spec sheet for ratings.

By performing the fuel conversion, some models can

operate on either natural gas or LP gas fuel. The

conversion may require addition/removal of the fuel

regulator spring and retainer. See Figure 9-7 for

specific information regarding conversion options. See

Section 9.8, Engine Ignition Timing, for engine timing

information.

Generator

Set Model,

kW

Engine

Spring Position

Additional

Adjustments

and Comments

Natural

Gas

LP

Gas

20

Ford

LRG-425

In Out See Section 9.8

30--125

GM 3.0 L,

4.3 L, 5.0 L,

5.7 L, 8.1 L,

8.1 L Turbo

In Out

Adjust fuel mixture

and timing. See

Sections 9.9, 9.10,

9.11, and 9.12

135--180

Detroit Diesel

Series 50

— — Natural gas only

200--275

Detroit Diesel

Series 60

— — Natural gas only

400--800 Waukesha — — Natural gas only

* Some models require new fuel kits for fuel conversion.

Figure 9-7 Fuel Conversion Data

Loading...

Loading...