165Section 9 Gas Fuel SystemsTP-6356 4/12

Auto Changeover Natural Gas/LPG Vapor

Operation

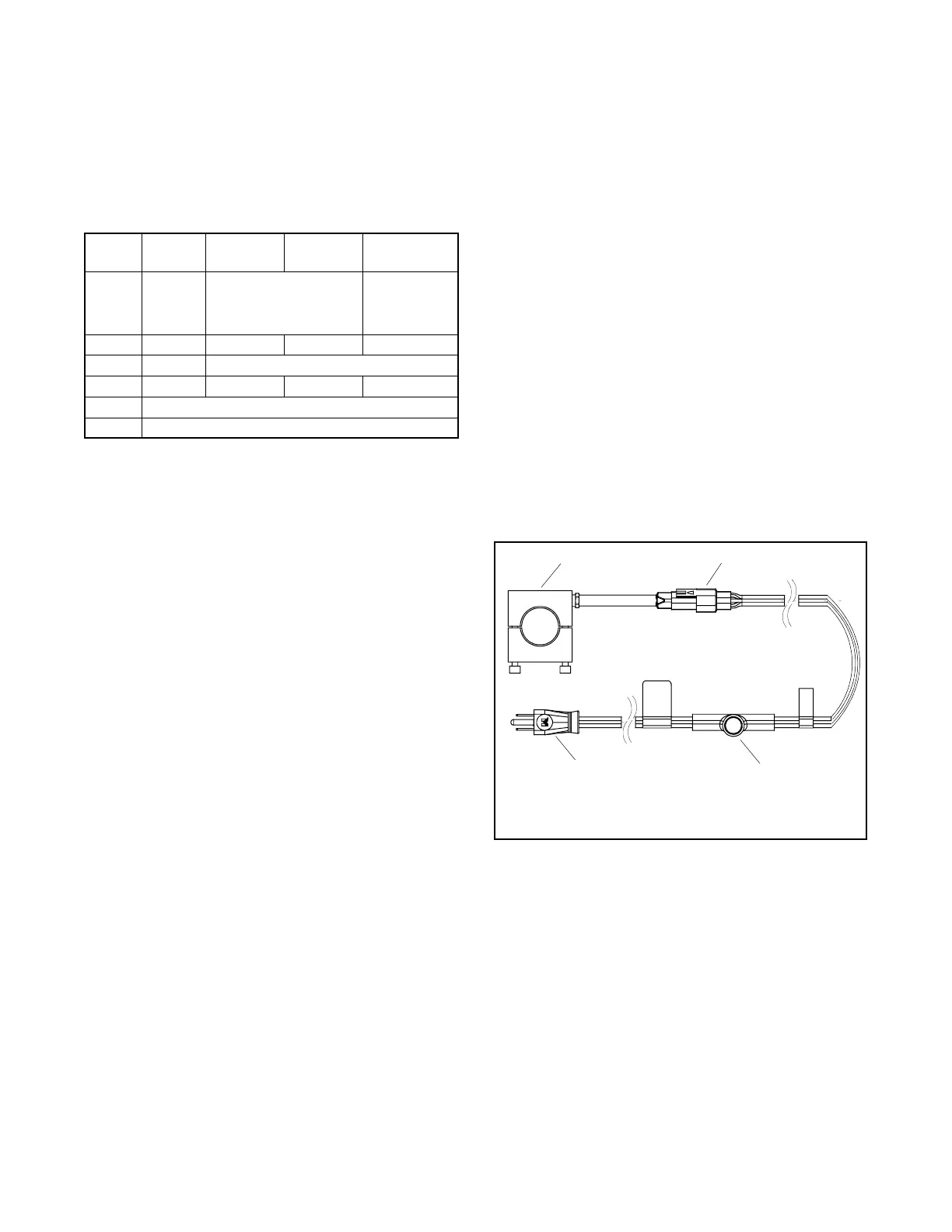

D Disconnect lead 65 from N5.

D Connect lead N5 to LFP2 relay common terminal.

D Connect lead 73A to the fuel solenoid valve (natural

gas).

D Connect lead 73B to the fuel solenoid valve (LPG

vapor).

Eng.

ECM

Natural

Gas

LPG

Vapor

LPG

Liquid

Auto

Changeover

73A

QCON--7

(NG fuel

solenoid

valve)

not used

QCON--7

(NG fuel

solenoid valve)

N5 not used 65 65 LFP2--COM

73B not used QCON--10 (LPG fuel solenoid valve)

65 not used N5 N5 not used

63 LFP1--NC low fuel pressure sensor (if used)

70E2 P6--B (15 amp fuse)

Figure 9-3 Gas F uel Electrical Connections

9.1.4 Fuel System Changeover Kits

(Dual Fuel)

Automatic Changeover

A changeover fuel system kit provides automatic

changeover from natural gas to LPG vapor. The

primary and backup fuels each have a fuel solenoid

valve. The primary fuel is natural gas; the backup fuel

is LPG vapor. Before starting, both fuel solenoid valves

are closed. When the generator set starts, the primary

fuel solenoid valve opens. The primary fuel line has a

pressure switch in series with a relay connected to the

start/run circuit.

When the primary fuel pressure drops below 0.6 kPa

(1.4 oz./in.

2

) or 6.4 cm (2.5 in.) water column , a relay

opens the backup fuel solenoid valve and closes the

primary fuel solenoid valve. When the primary fuel

pressure rises above 0.6 kPa (1.4 oz./in.

2

)or6.4cm

(2.5 in.) water column, the generator set uses the

primary fuel. Contact an authorized service

distributor/dealer for kit availability.

Emissions certified models use a single electronic-

controlled pressure regulator (EPR) for both fuels. A tee

fitting connects both fuels together upstream of the

EPR. During operation when using the secondary fuel, it

is normal for a small amount of secondary fuel to seep

back through the primary fuel solenoid valve. To counter

this situation, one of two methods is used depending

upon the generator set model: (1) a second solenoid

valve (identical to the primary fuel solenoid valve) is

installed in a reverse configuration on the primary fuel

side or (2) a small vent line is installed between the

primary fuel inlet and the air intake through a fuel

solenoid valve.

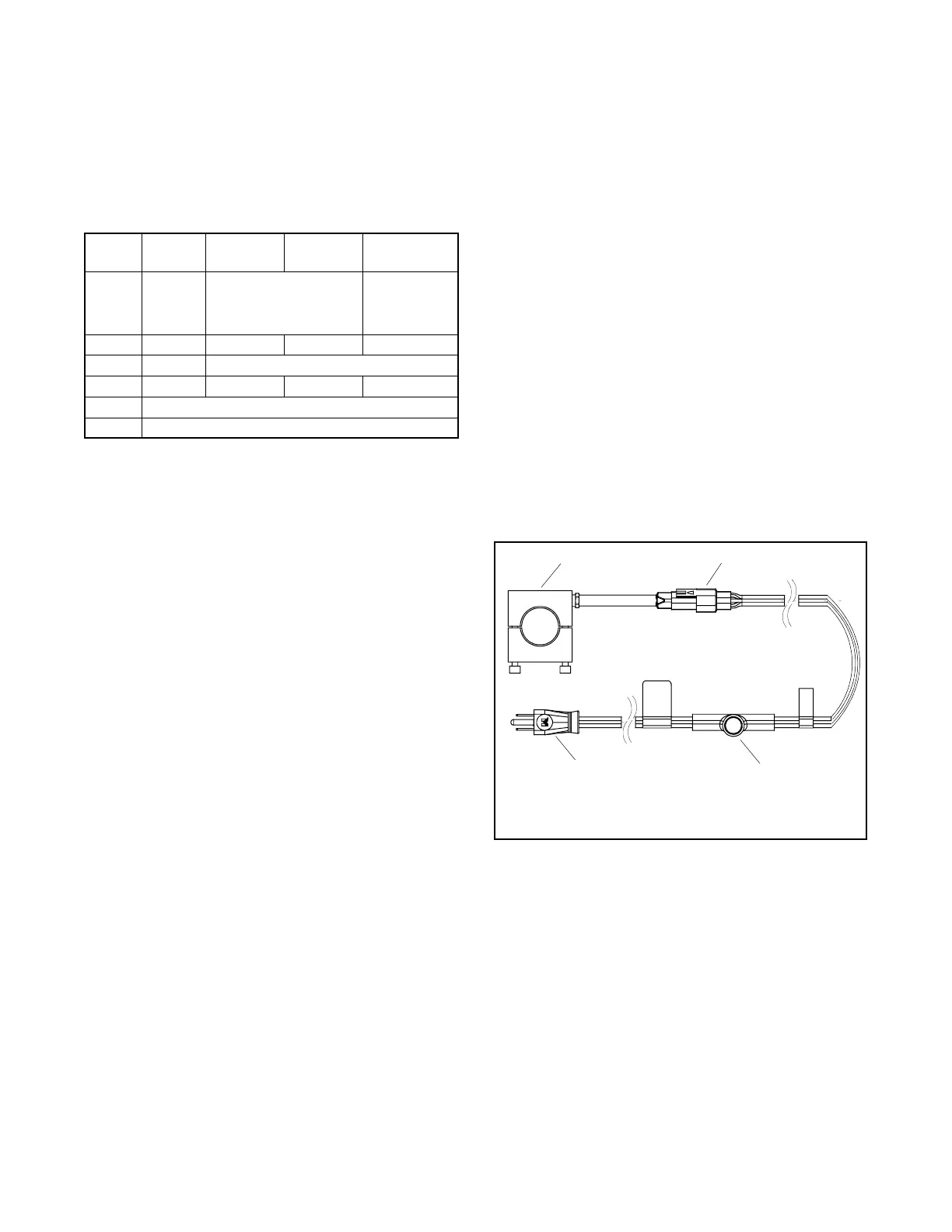

9.1.5 Crankcase Ventilation (CCV)

Heater Kit GM78171-KP1

(125/150REZG models)

The crankcase ventilation (CCV) heater kit provides a

controlled heating source to the crankcase ventilation

system preventing freezing water buildup during cold

weather. The thermostat turns on at 4_C(40_F) and

turns off at 16_C(60_F) reducing energy consumption.

SeeFigure9-4.

1. Heater element

2. Inline connector

3. Thermostat

4. AC power cord

TT-1560

1 2

3

4

Figure 9-4 Crankcase Ventilation Heater Kit

Loading...

Loading...