182 Section 9 Gas Fuel Systems TP-6356 4/12

d. Connect an ignition timing light to the engine.

Follow the ignition timing light manufacturer’s

instructions.

Typically the ignition timing light connects to the

starting battery for power and the inductive

pickup goes on the no. 1 spark plug wire. The

no. 1 spark plug is in the front left side of the

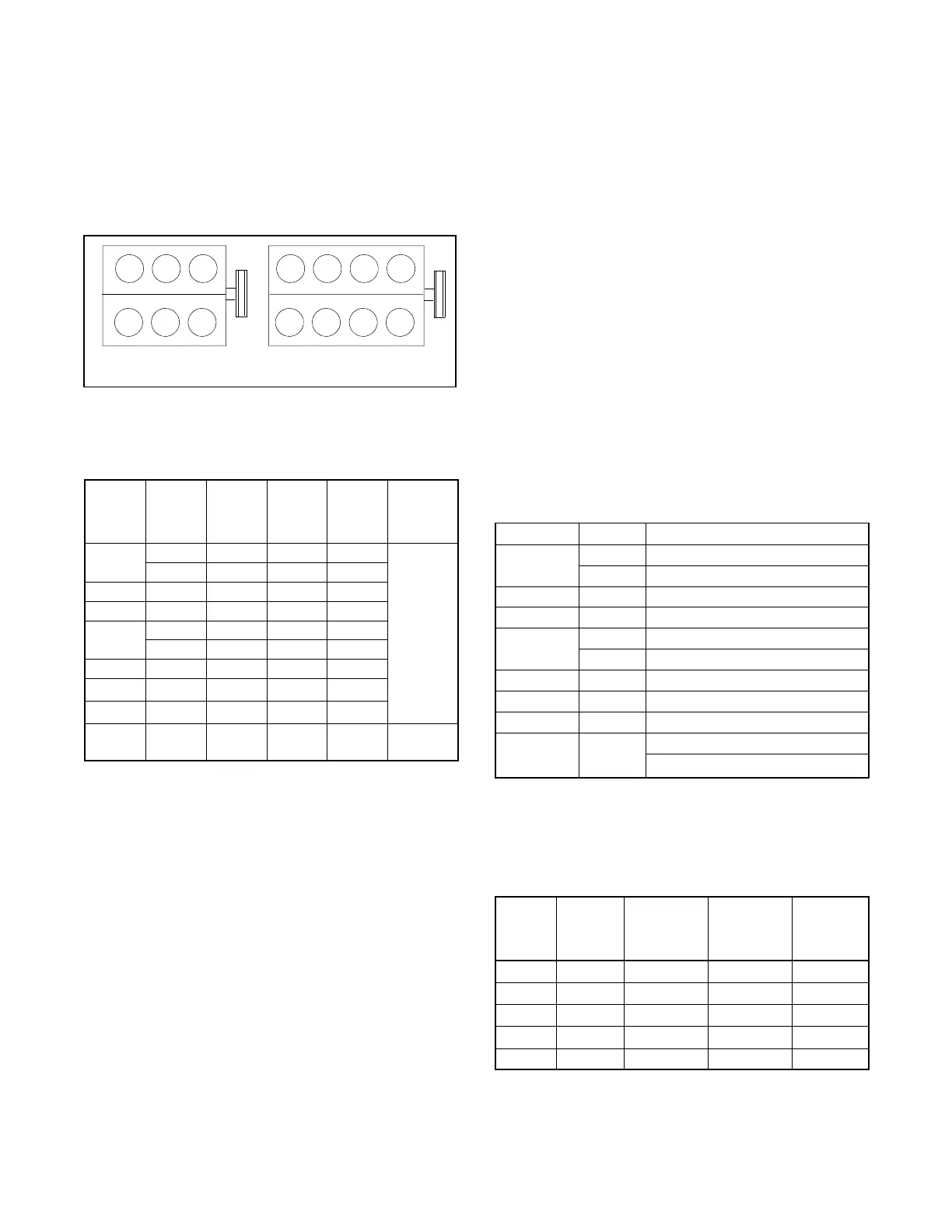

engine. See Figure 9-41.

TT-1295

11

30--45 kW 50/60 kW

Figure 9-41 Engine No. 1 Cylinder/Spark Plug

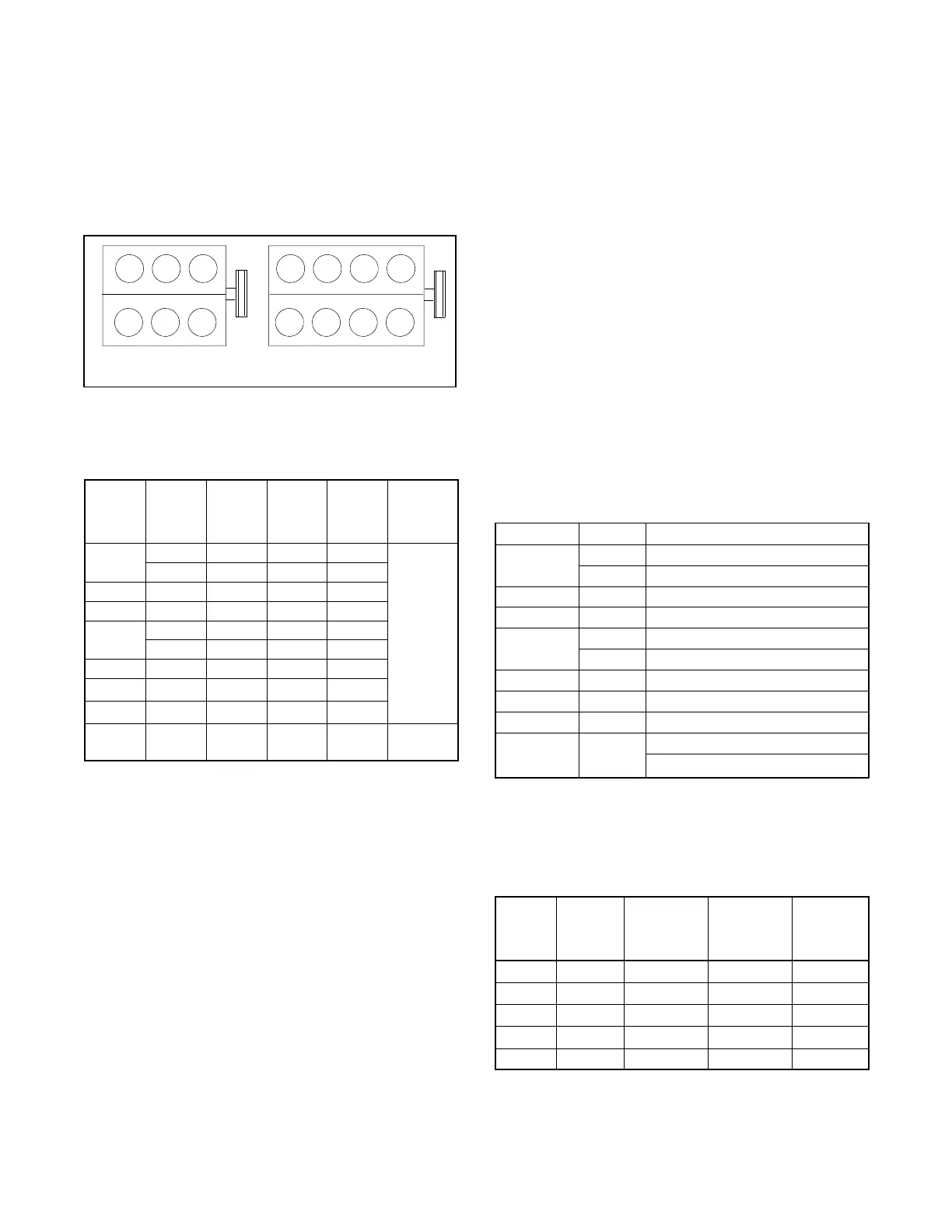

e. Set the ignition timing light adjustment to the

value shown in Figure 9-42.

Model,

kW

Engine

NG

Timing

_BTDC

LP Gas

Timing

_BTDC

Dual

Fuel

Timing

_BTDC

Spark

Plug

Gap, mm

(in.)

30

4.3 L 32 28 32

0.89

(0.035)

3.0 L 0 0 0

35 4.3 L 32 28 32

45 4.3 L 32 28 32

50

5.7 L 36 28 32

5.0 L 36 28 32

60 5.7 L 36 28 32

80 8.1 L ECM ECM ECM

100 8.1 L ECM ECM ECM

125 8.1 L ECM ECM ECM

0.64

(0.025)

Figure 9-42 Engine Ignition Timing

f. Place the generator set master switch in the

RUN position to start the generator set.

g. Point the ignition timing light at the engine

timing plate mark and slowly turn the distributor

CW or CCW until the crankshaft pulley groove

aligns with the engine timing plate mark.

h. Place the generator set master switch in the

OFF position to stop the generator set.

i. Tighten the distributor hold-down clamp to

25 Nm (18 ft. lb.) being careful not to alter the

distributor position.

j. 30 kW model with the 3.0 L GM engine only.

Remove the lead from pin B lead at the battery

positive (+) terminal. Unplug GM39651 service

harness adapter from the distributor.

Reconnect the 4-pin harness connector to the

base of the distributor.

k. Disconnect the ignition timing light from engine.

8. Adjust the fuel mixture using Section 9.12.

9.12 Fuel Mixture Adjustment

(Oxygen Sensor Service Kit

GM29385 )

(30--125 kW GM-Powered Models with

Woodward and E-Controls Governor)

Adapted from Service Bulletin SB-634.

This section details fuel mixture adjustment for General

Motors engine-powered generator sets. Figure 9-43

lists specification numbers for generator sets including

engine models.

Model, kW Engine Spec No.

30

4.3 L GM22383-GA1, 7, 10, 13, 14

3.0 L GM22316-GA1, 4

35 4.3 L GM22383-GA2, 8, 11, 15, 16

45 4.3 L GM22383-GA3, 9, 12, 17, 18

50

5.7 L GM13686-GA1, 3, 5, 7

5.0 L GM21302-GA1, 5, 7

60 5.7 L GM21302-GA2, 6, 8

80 8.1 L GM22407-GA1,2,3,4

100 8.1 L GM22407-GA5,6,7,8

125 8.1 L

GM20568-GA1, 2

GM25339-GA1,2,3,4

Figure 9-43 Specification Numbers

Figure 9-44 provides the differences in engine

components and the optimum air/fuel mixture measured

with an oxygen sensor in volts.

Model,

kW

GM

Engine

Fuel Mixer

Type

Electronic

Control

Unit (ECU)

Type

Air/Fuel

Mixture

Measured

in V olts

30 3.0 Nolff E-Controls 2.50--2.65

30--45 4.3 Woodward PSI 2.35--2.45

50/60 5.0, 5.7 Woodward PSI 2.60--2.80

80/100 8.1 Nolff E-Controls 2.50--2.65

125 8.1 Turbo Nolff E-Controls 2.50--2.65

Figure 9-44 Engine Components and Optimum

Air/Fuel Mixture Values

Loading...

Loading...