SEN03775-04 10 Structure, function and maintenance standard

24 PC130-8

Function

q This valve reduces the swing back generation

in the swing body by the inertia of the swing

body, the backlash and rigidity of the machin-

ery system, and the compression of the

hydraulic oil when the swing is stopped.

q The valve contributes in preventing collapsing

of load when the swing is stopped and also

contributes in reducing cycle time (enhances

the positioning performance, enabling you to

proceed to the next work quicker than ever).

Operation

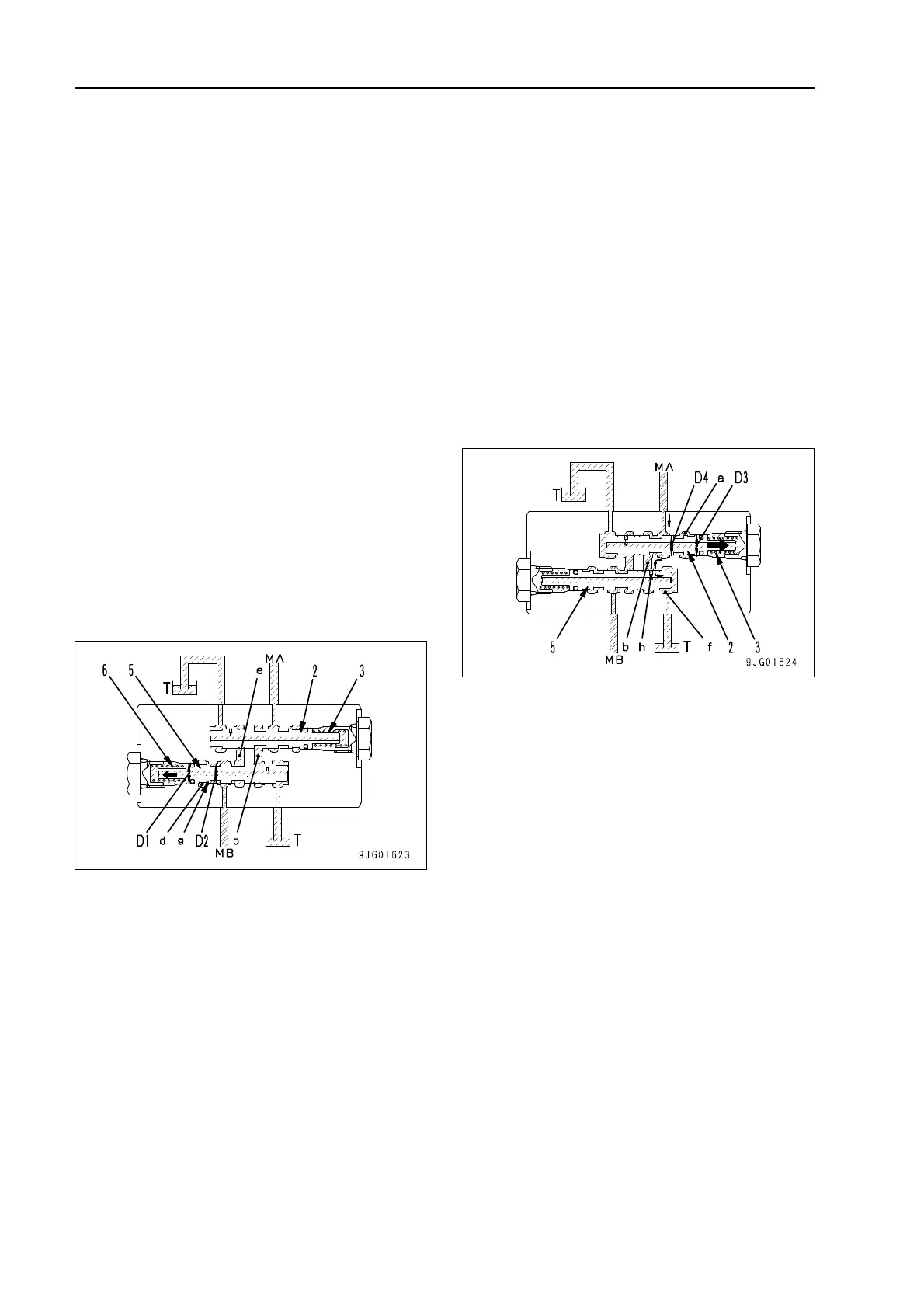

1. When port (MB) brake pressure is generated

q Pressure (MB) is conducted to chamber (d) via

notch (g).

q The pressure compresses spring (6) by use of

the difference in areas of circles (øD1 > øD2)

of spool (5) and moves

spool (5) to the left

side.

q Port (MB) o chamber (e) will be intercon-

nected.

q Since pressure (MA) is lower than the set pres-

sure of spring (3), spool (2) does not move and

the pressurized oil is kept in. Thus the braking

force is ensured.

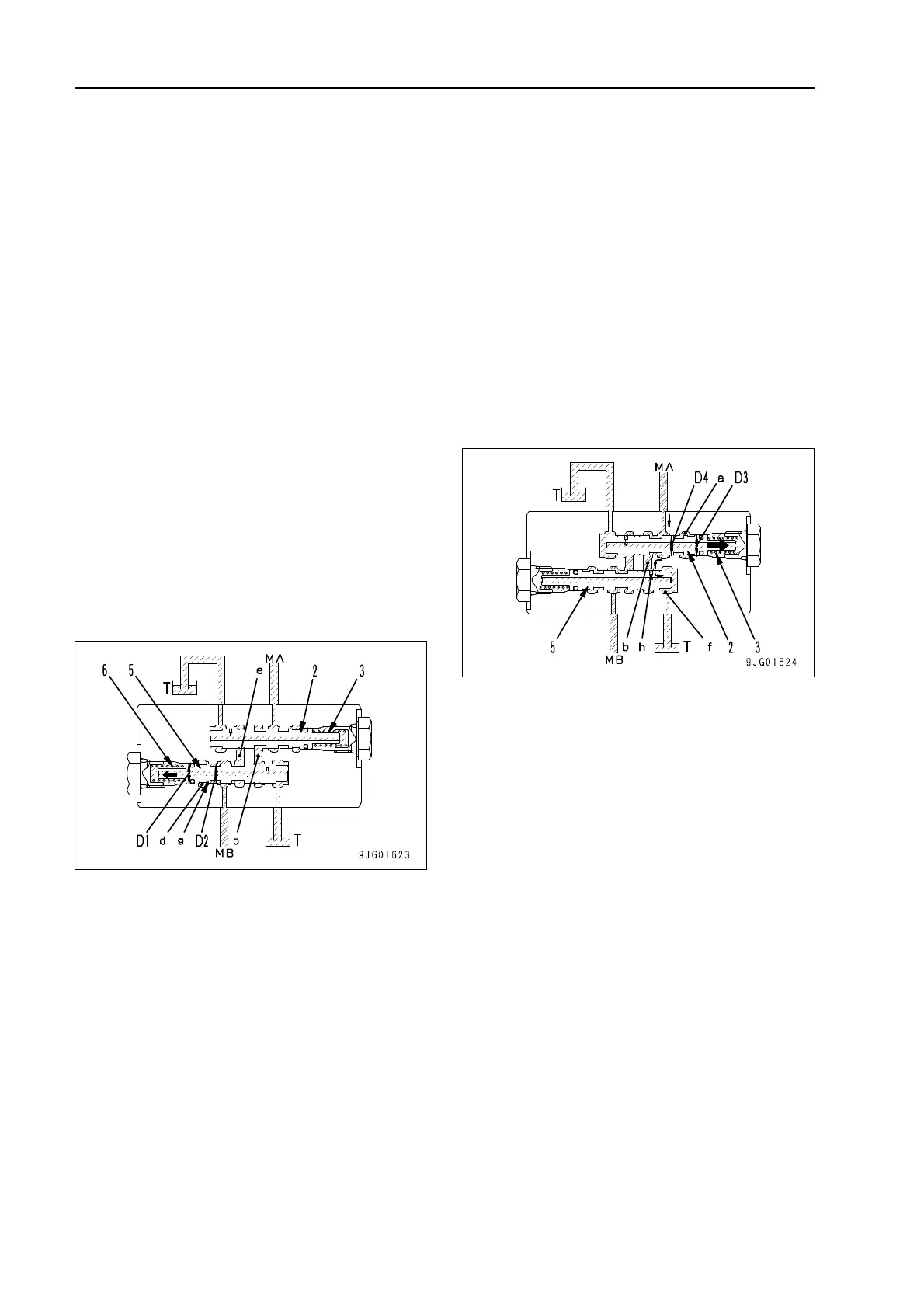

2. When motor is stopped temporarily

q The motor rotation is reversed by the closing

pressure generated at port (MB). (1st time:

reverse rotation)

q Reversing pressure is generated on port (MA).

Pressure (MA) is conducted to chamber (a).

q The pressure compresses spring (3) by use of

the difference in areas of circles (øD3 > øD 4 )

of

spool (2) and moves spool (2) to the right

side.

q Port (MA) o chamber (b) will be intercon-

nected.

q Ports (b) and (f) will be interconnected through

the drilled hole (h) on spool (5). This intercon-

nection bypasses the reversing pressure on

port (MA) to port (T), thereby preventing the

reverse rotation of the 2nd time.

Loading...

Loading...