Testing swing circle bearing

clearance 1

a Testing tools for swing circle bearing clearance

a When testing the swing circle bearing clear-

ance installed to the machine, perform the fol-

lowing procedure.

k Stop the machine on a level ground and

lower the work equipment to the ground.

k Do not put your hands or feet under the

undercarriage during test.

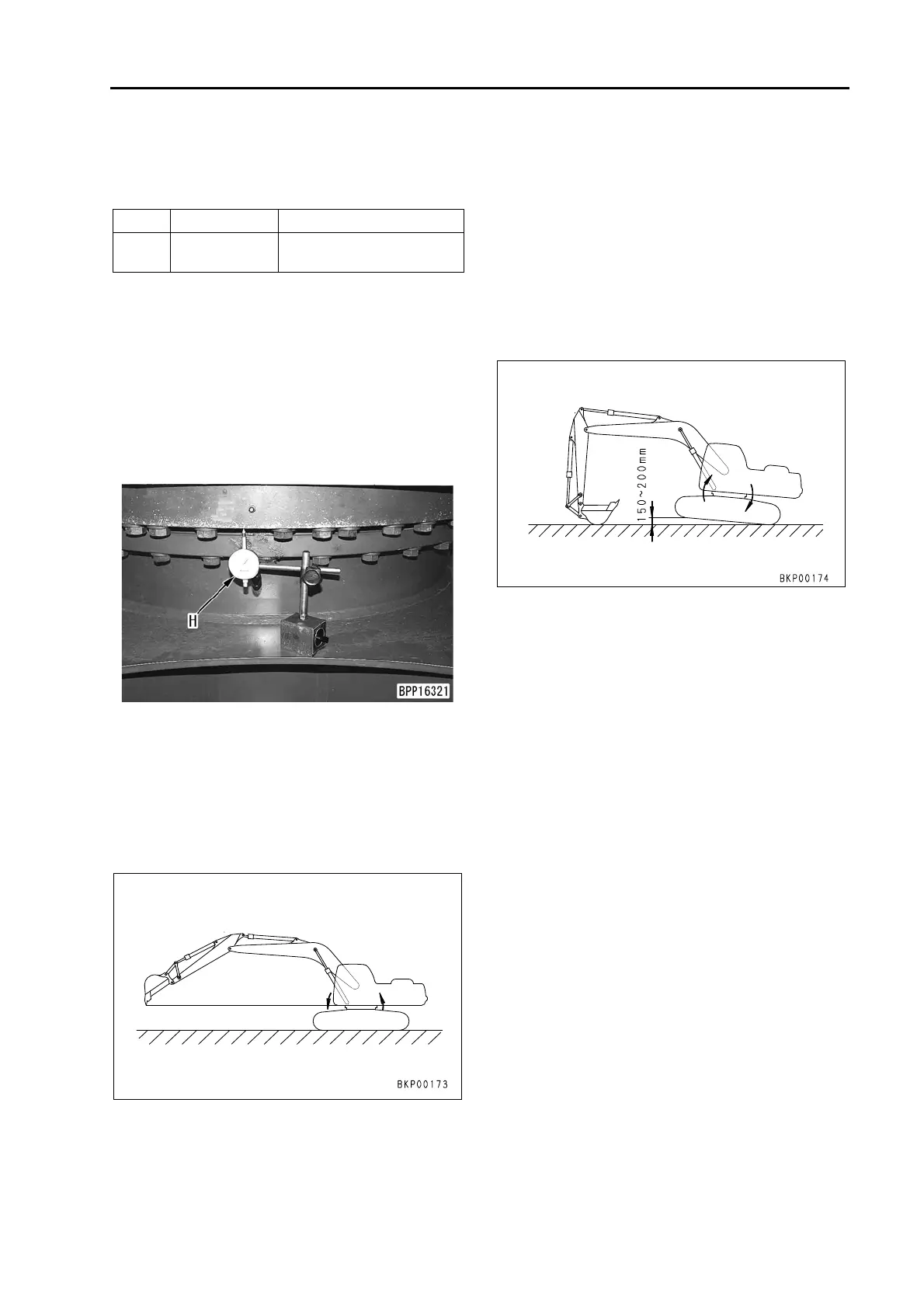

1. Fix dial gauge H to the track frame and apply

the probe to the lower end of the outer race.

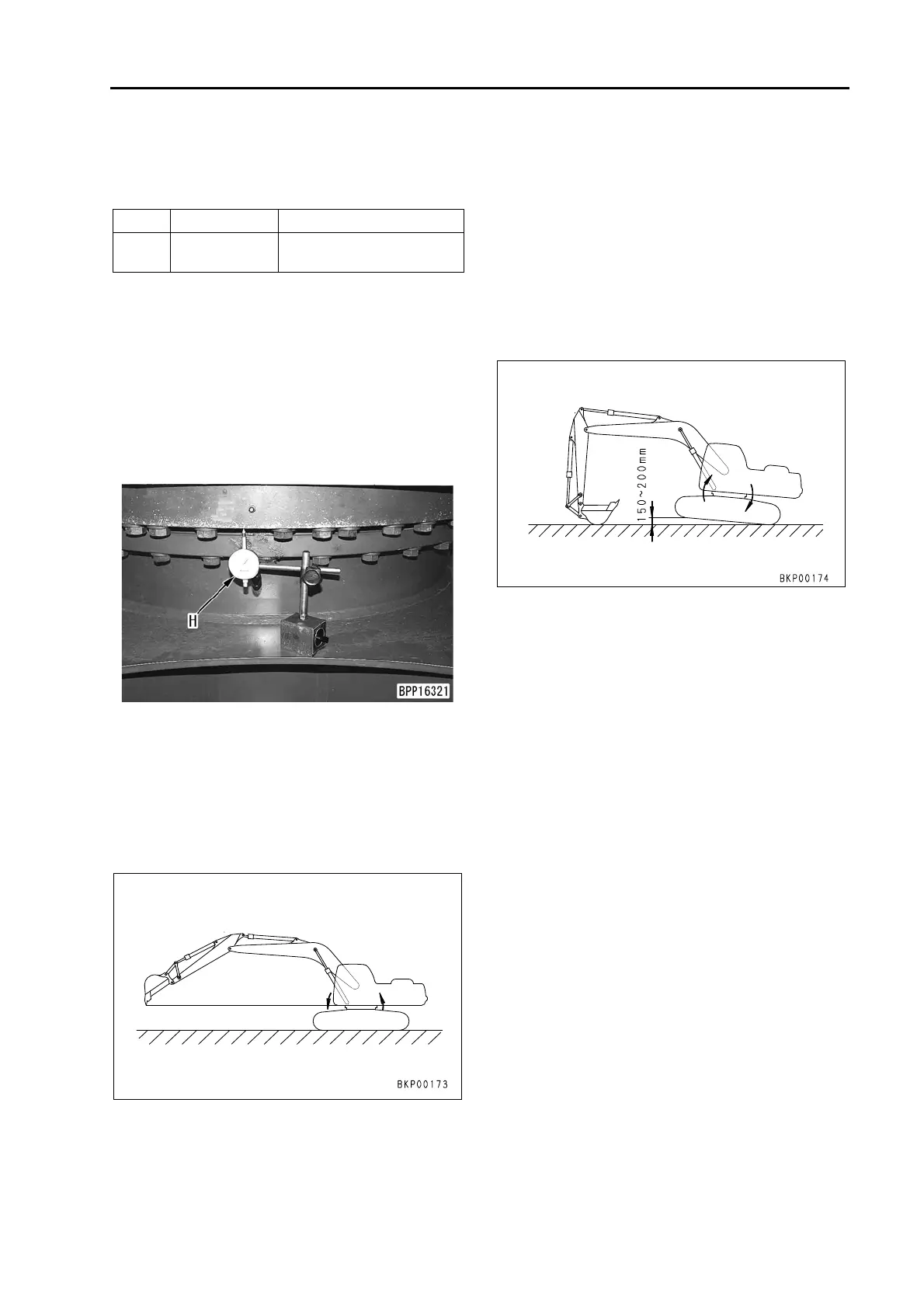

2. Set the work equipment to the maximum reach

position and set the bucket tip to the height of

the under side of the revolving frame.

a At this time the front of the upper structure

lowers and the rear rises.

3. Set dial gauge H to the 0 point.

4. Set the arm almost perpendicular to the

ground and lower the boom until the front track

shoe floats.

a At this time the front of the upper structure

rises and the rear lowers.

5. Under this condition, read dial gauge H.

a The value indicated by dial gauge H is the

clearance of the bearing.

a For the standard value, see Structure,

function and maintenance standard,

"Swing circle".

6. Return the machine to the condition of step 2

and check that dial gauge H indicates 0.

a If the dial gauge does not indicate 0,

repeat steps 2 through 5.

Symbol Part No. Part name

H

Commercially

available

Dial gauge

Loading...

Loading...