SEN04124-00 40 Troubleshooting

6 PC130-8

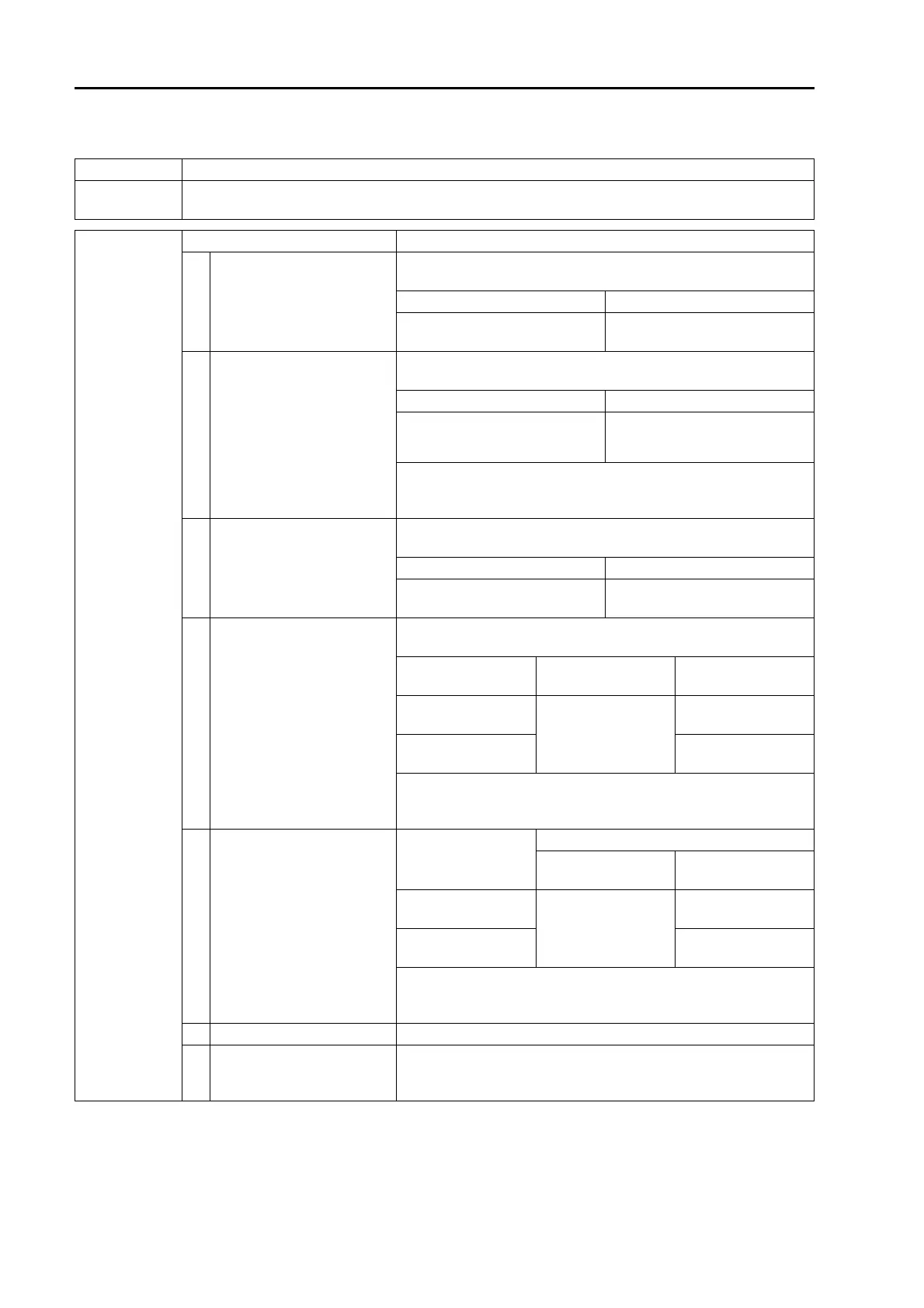

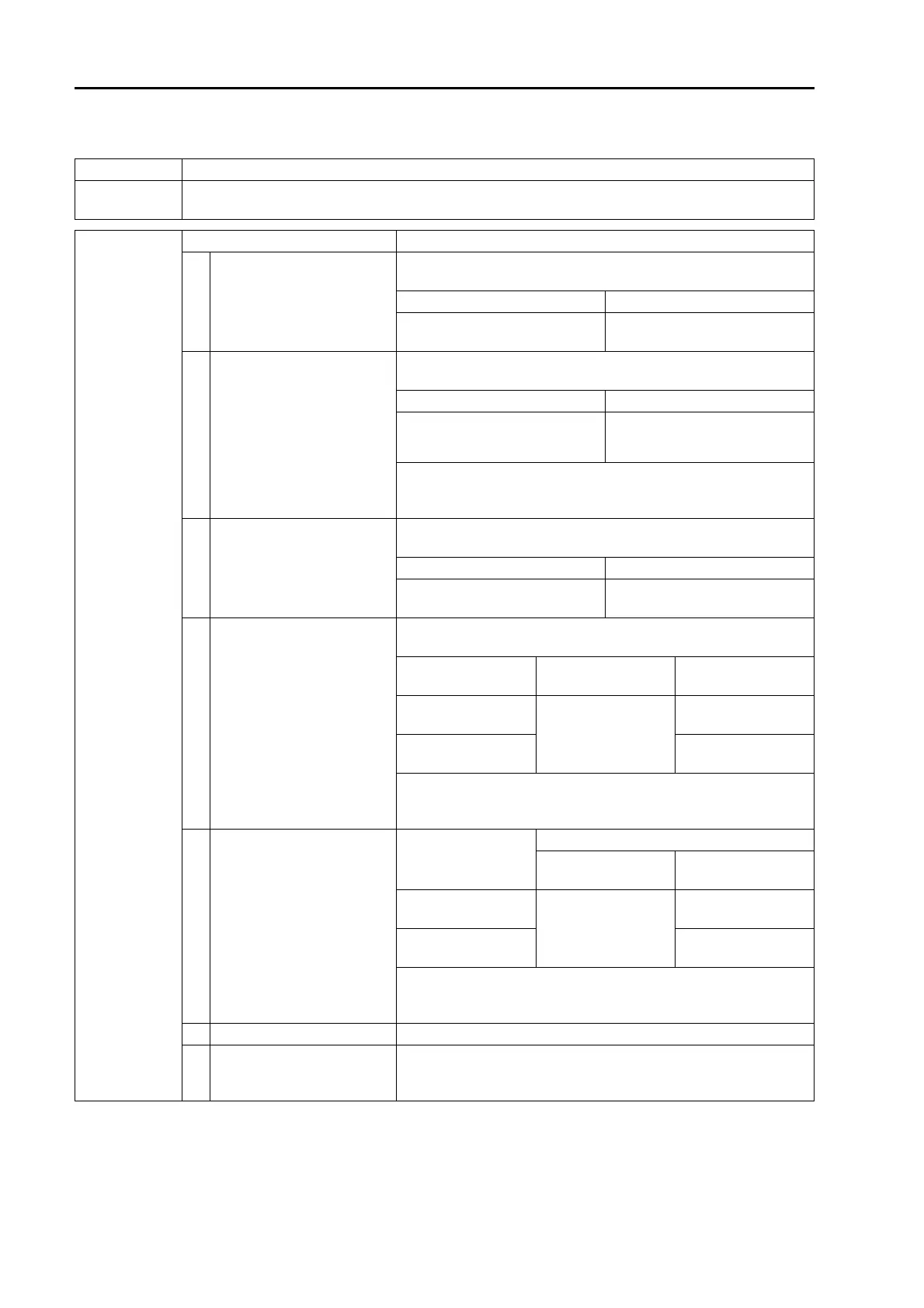

H-1 Speed or power of all work equipment, swing, and travel are low 1

Trouble • Speed or power of all work equipment, swing, and travel are low.

Related

information

• Conduct the troubleshooting in working mode P.

Possible causes

and standard

value in normal

state

Cause Standard value in normal state/Remarks on troubleshooting

1 Malfunction of unload valve

a Keep the engine stopped for the preparations, and keep it

running at high idle during the troubleshooting.

Control levers Unload pressure

All levers in NEUTRAL

2.8 ± 1.0 MPa

{28 ± 10 kg/cm

2

}

2

Defective adjustment or

operation of main relief valve

(power-up mode)

a Keep the engine stopped for the preparations, and keep it

running at high idle during the troubleshooting.

Control lever Main relief pressure

Arm relieved in IN direction

34.8 MPa

{355 kg/cm

2

}

If the oil pressure cannot be set normally by adjustment, the main

relief valve may be malfunction or may have an internal defect.

Check the main relief valve directly.

3

Malfunction of self-pressure

reducing valve

a Keep the engine stopped for the preparations, and keep it

running at high idle during the troubleshooting.

Control levers Control circuit basic pressure

All levers in NEUTRAL

3.2 ± 0.5 MPa

{33 ± 5 kg/cm

2

}

4

Defective adjustment or

operation of PC valve

a Keep the engine stopped for the preparations, and keep it

running at high idle during the troubleshooting.

Measured oil

pressure

Measurement

conditions

Oil pressure ratio

Pump discharge

pressure

Swing lock: ON

Arm: Relieved in IN

direction

1

PC valve output

pressure

Approx. 0.6

(Approx. 3/5)

If the oil pressure cannot be set normally by adjustment, the PC

valve may be malfunction or may have an internal defect. Check

the PC valve directly.

5

Defective adjustment or

operation of LS valve

Measured oil

pressure

Oil pressure ratio

All levers in

NEUTRAL

Bucket curled

(Lever at stroke end)

Pump discharge

pressure

Almost same

pressure

1

LS valve output

pressure

Approx. 0.6

(Approx. 3/5)

If the oil pressure cannot be set normally by adjustment, the LS

valve may be malfunction or may have an internal defect. Check

the LS valve directly.

6 Malfunction of servo piston The servo piston may have malfunction. Check it directly.

7 Piston pump defective

If there is none of the causes listed above, the piston pump may

have problems of lowering of performance, malfunction, internal

defect, etc.

+2.0

–1.0

+20

–10

Loading...

Loading...