4. Bleeding air from swing motor

1) Turn the swing lock switch "ON" and run

the engine at low idle for 5 minutes.

a Bleed air from the swing motor by

applying the S-port pressure.

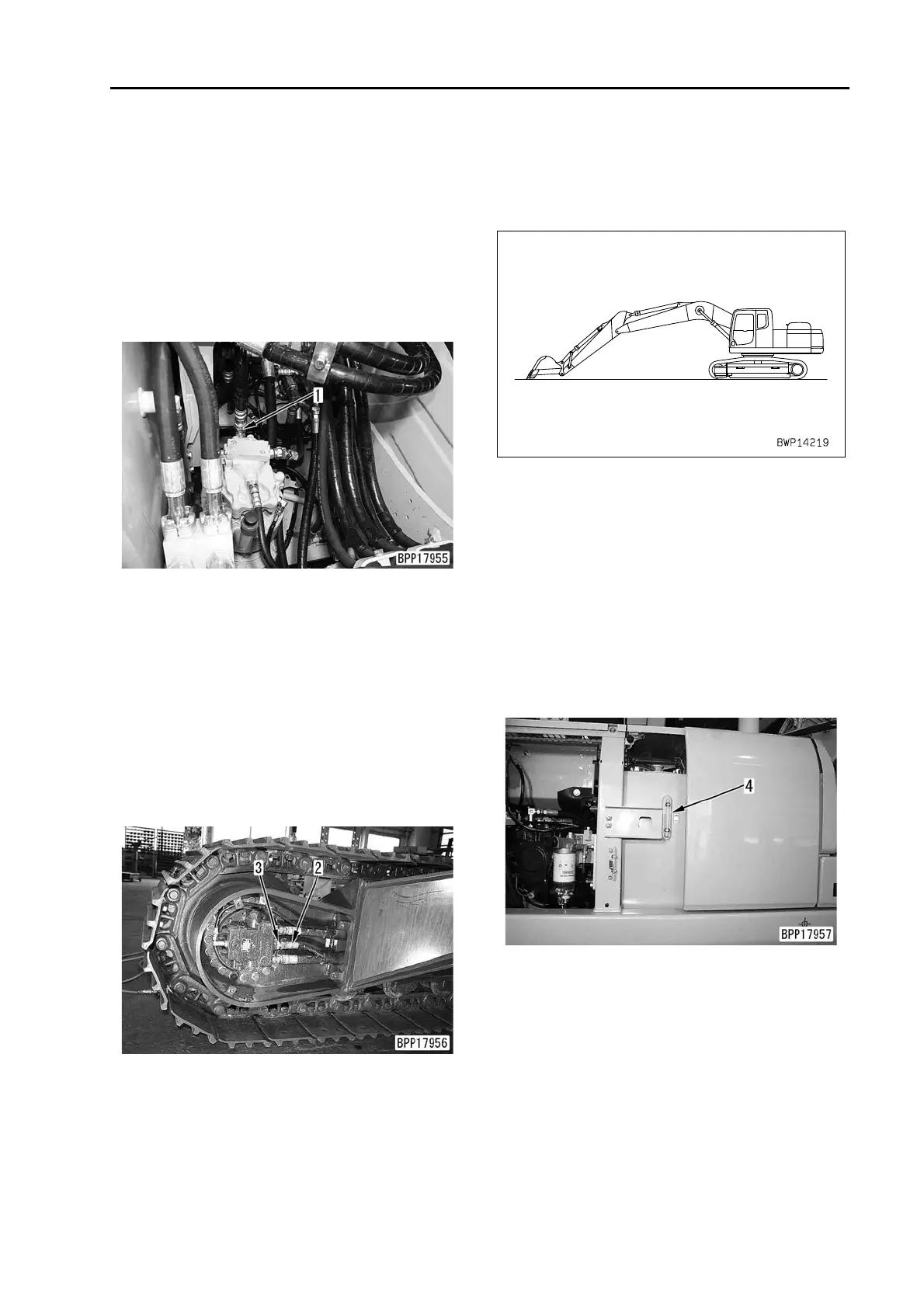

2) Remove the swing motor top cover, dis-

connect hose (1) from the swing motor,

and block the hose with a plug.

a Use the following plug to block the

hose.

07379-70628 (Plug #06)

3) Run the engine at low idle and check that

oil flows out of elbow.

a If no oil flows out of the elbow, per-

form step 1) again.

4) Connect hose (1) under its normal condi-

tion.

5. Bleeding air from travel motor

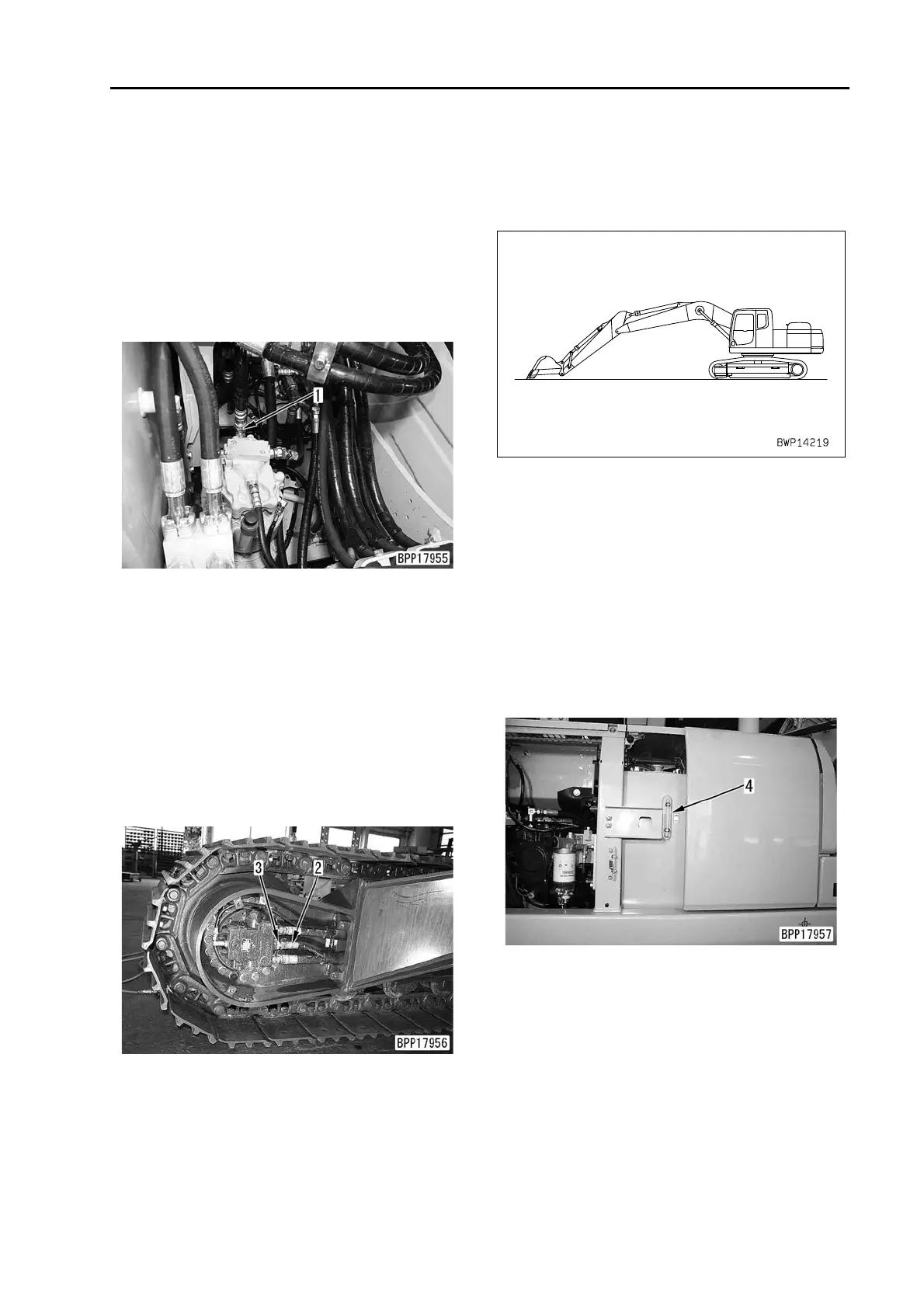

1) Remove the travel motor cover and dis-

connect motor drain hose (2).

2) Run the engine at low idle and check that

oil flows out of nipple (3).

6. Checking oil level and starting work

1) Run the engine, retract the arm cylinder

and bucket cylinder to the stroke ends,

lower the work equipment to the ground,

and stop the engine.

2) Check the oil level by sight gauge (4) on

the rear side of the hydraulic tank.

a If the oil level is below line L, it is

insufficient. Add oil.

a The oil level changes according to the

oil temperature. Add oil when the oil

level is out of the following standard

ranges.

q When oil temperature is 10 30°C:

Between line H and line L

q When oil temperature is 50 80°C:

Near line H

Loading...

Loading...