SEN04127-02 50 Disassembly and assembly

4 PC130-8

Installation

q Carry out the installation in the reverse order of

removal.

[*1]

a Set the boot slit facing outward and downward.

a The boot is designed with fire safety to prevent

fuel from splashing onto the hot engine if fuel

leaks.

[*2]

k Never bend a high-pressure pipe for the

convenience sake.

k The clamp used for fixing a high-pressure

pipe must be a genuine Komatsu part and it

must be tightened to the specified torque.

k Be sure to install the boot to the sleeve nut

after installing the high-pressure pipe.

a Before installing a high-pressure pipe, confirm

the following points. If any abnormality was

found, replace it with new one. Otherwise,

leakage of fuel can result.

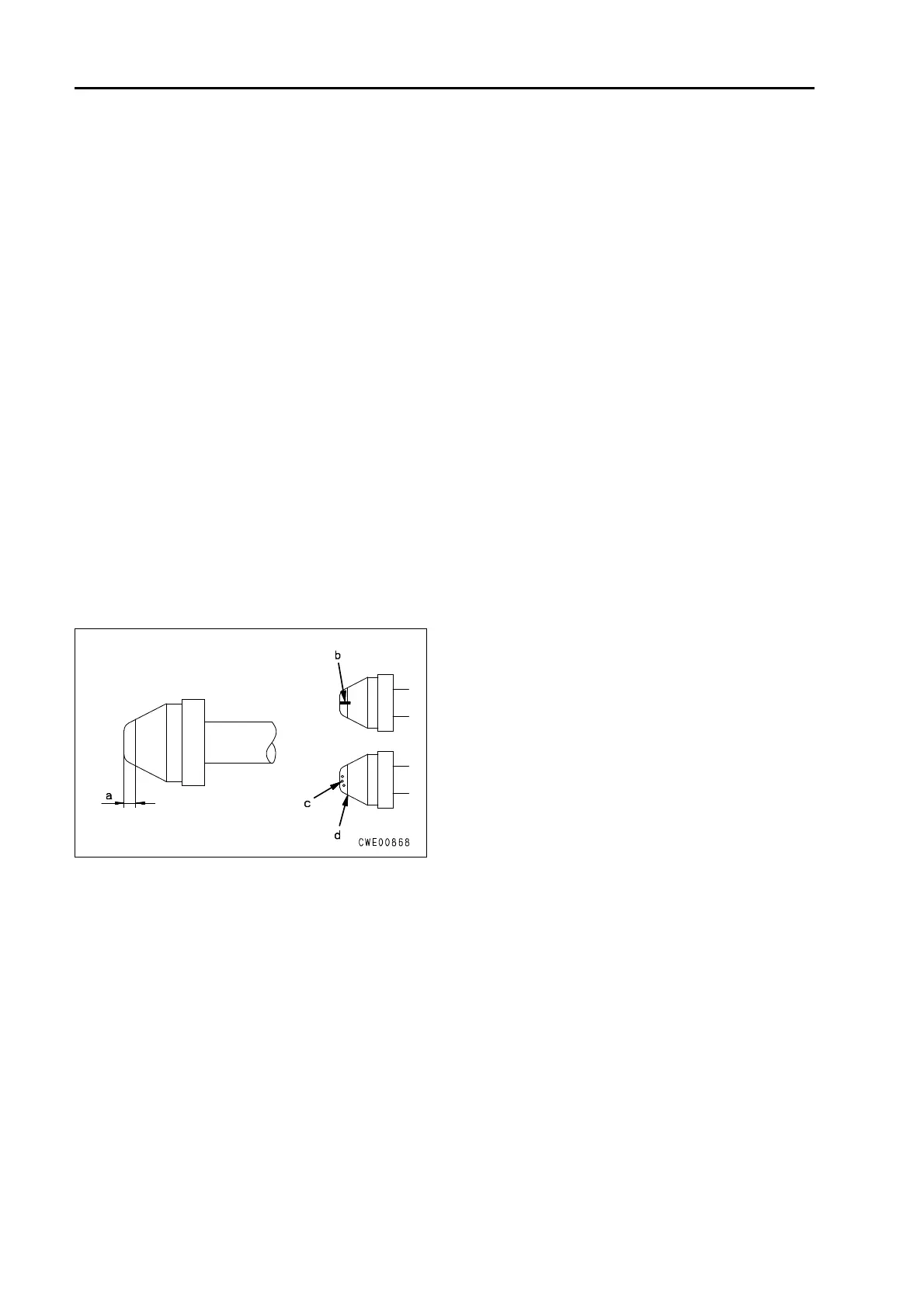

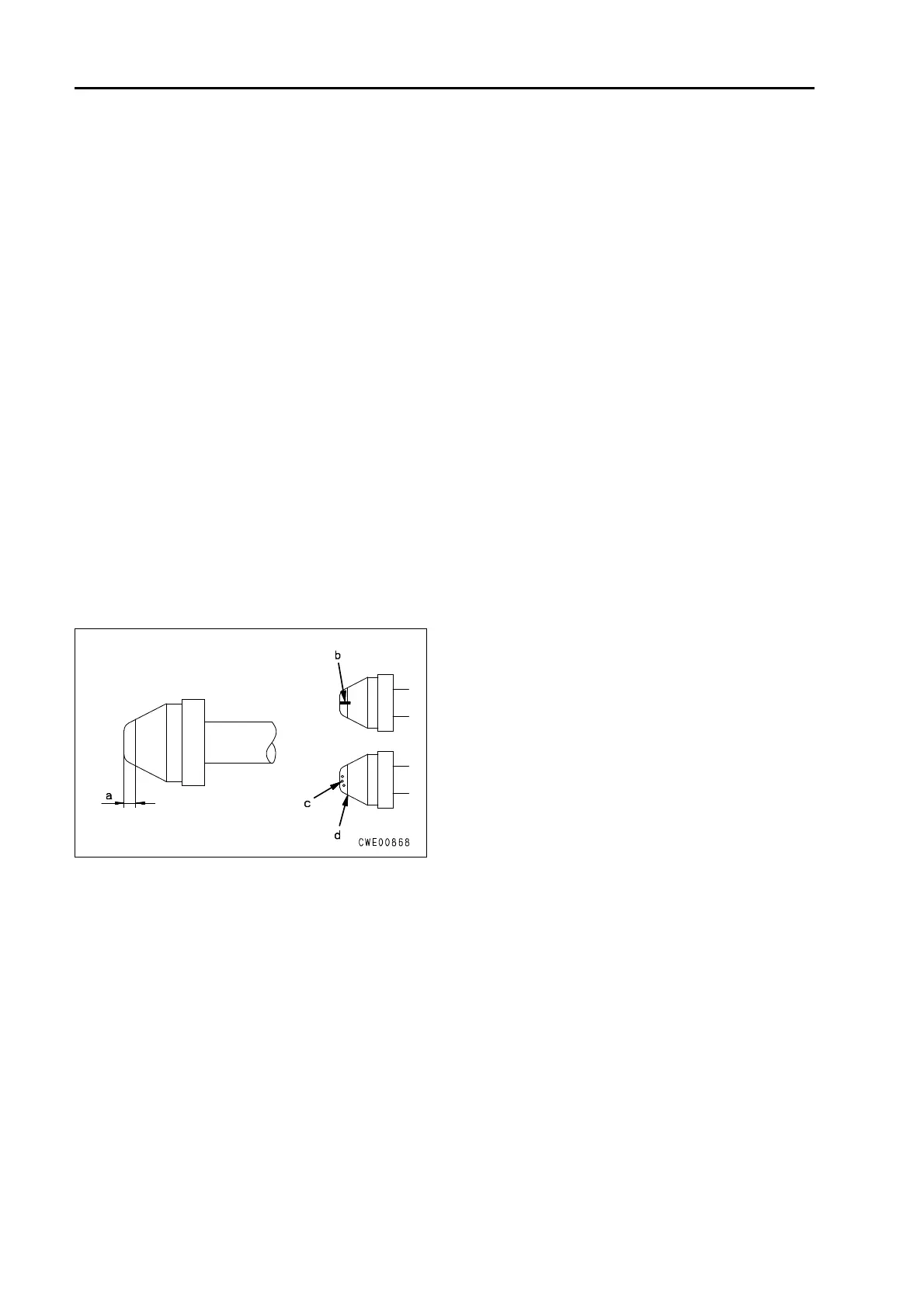

q No visible striations (b) or patchy dents (c) in

the taper seal portion of the connection ( (a)

portion: area 2 mm inside the tip).

q No deformation in portion (d) (at the end of the

taper seal portion: 2 mm inside the tip).

3 Sleeve nut (10) on the common rail side:

25.5 – 29.4 Nm {2.6 – 3.0 kgm}

3 Sleeve nut (11) on the supply pump side:

18 – 23 Nm {1.9 – 2.3 kgm}

[*3]

3 Joint bolts (14) and (15):

24.5 – 34.3 Nm {2.5 – 3.51 kgm}

3 Joint bolt (16):

19.6 – 29.4 Nm {2.0 – 3.0 kgm}

[*4]

a For mounting bolt (20), install M6 bolt with LT-

2A.

[*5]

3 Pump gear mount nut:

65 – 75 Nm {6.6 – 7.6 kgm}

Loading...

Loading...