50 Disassembly and assembly SEN04130-01

PC130-8

31

Assembly

Only the precautions for assembling the travel PPC

valve assembly are discribed.

a When

assembling, clean and inspect the parts

closely and take care fully so that dirt, rust,

flaw, etc. will not cause a trouble.

a When inst

alling piston (7), apply grease (G2-

LI) to its outside and the inside of the body

hole.

a In

stall spring (4) with its small diameter side on

the shim (3) side.

q Diameter of spring (Inside diameter)

Small diameter side: 4.9, Large diameter

side

: 5.55

a Assem

ble shaft (16) with the following proce-

dure.

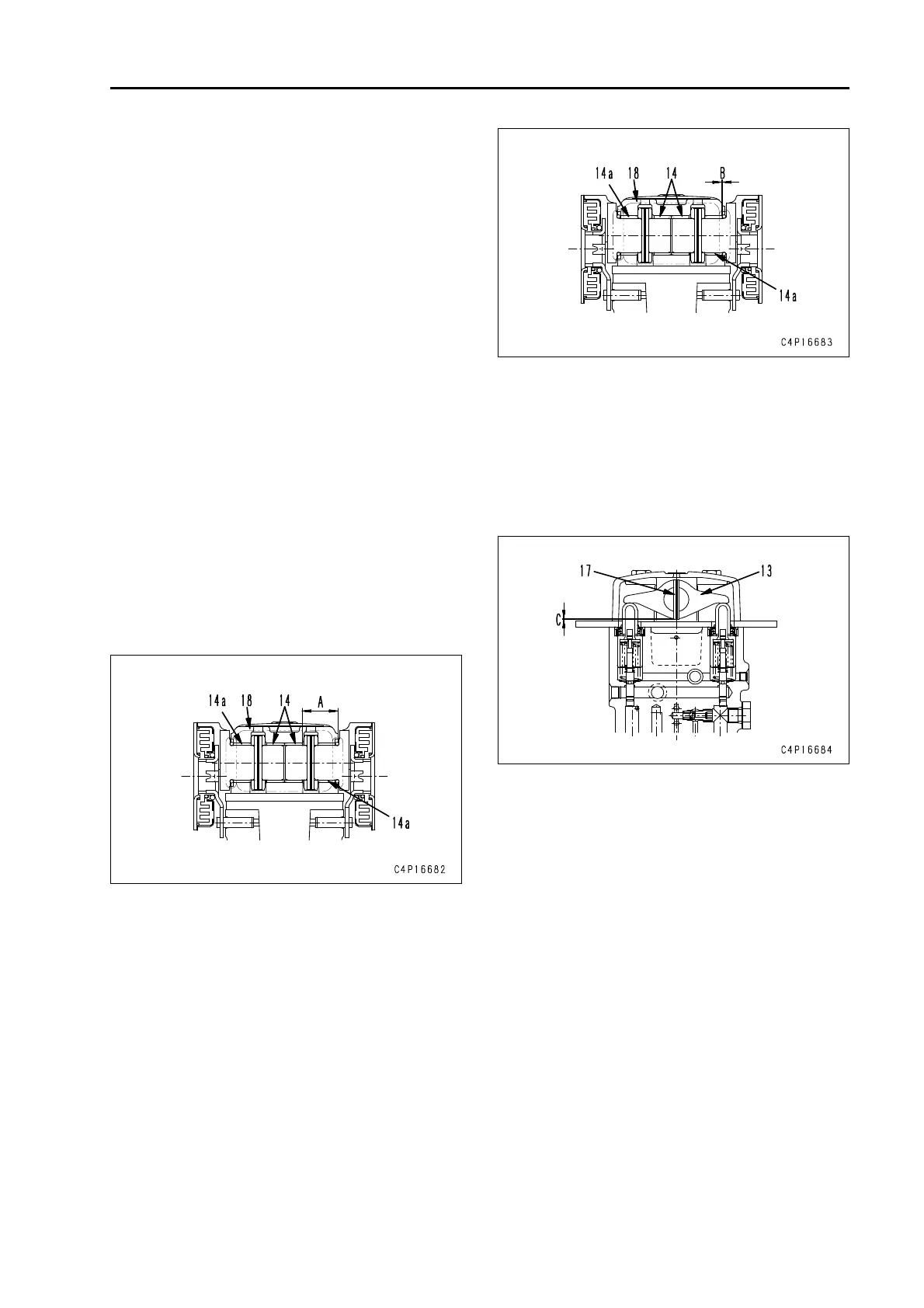

1) Using tool T2,

install bushing (14) to case.

a In

stall bushing from 10° chamfered

side.

a Inst

alling dimension (A) of the bush-

ing should be as follows.

q A: 20.4 ± 0.3 mm

a Do no

t apply shock load to the bush-

ing directly.

2) Using tool T3, install bushing (14 a ) t o

case.

a In

stall bushing from 10° chamfered

side.

a Inst

alling dimension (B) of the bush-

ing (14a) should be as follows. (End

surface of bushing will tightly fit to the

end surface of case.)

q B: 0 mm

a Do no

t apply shock load to the bush-

ing directly.

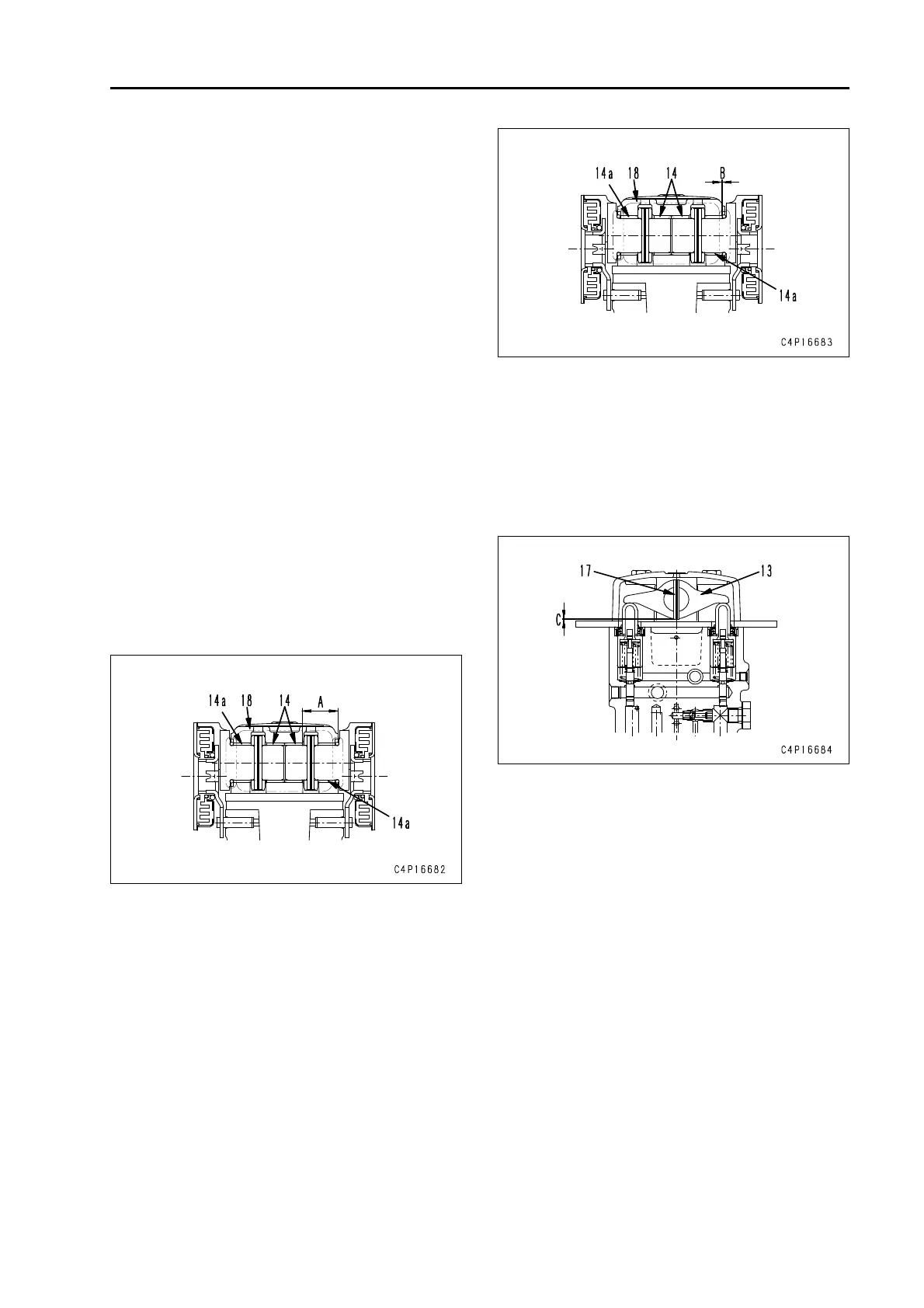

3) Install lever (13).

4) Install shaft (16).

5) Using tool T4, insatll pin

(17).

a In

stalling dimension (C) of the pin

(17) should be as follows.

q C: 0 – 0.5 mm

a Do

not apply shock load to the pin

directly.

a Apply grease (G2-LI) to the rocking part of

shaft (16) and the contact surfaces of lever

(13) and piston (7) and the contact surfaces of

damper (21) and pin (20).

2 Quantity of grease (G2-LI)

Rocking part of shaft:

4 – 8 cc/periphery

Contact surfaces of lever and piston:

0.3 – 0.8 cc/place

Contact surfaces of plate and pin:

0.3 – 0.8 cc/place

a Install washer (12) 1.6 mm thick first. If the dif-

ference between both sides at the stroke end

of the lever exceeds 0.7°, change the washer

thickness to reduce the difference to below 0.7

°. (If the washer thickness is reduced by 0.3

mm, the stroke end angle is increased by 0.39

°.)

q Thickness of washer t: 1.0, 1.3, 1.6

Loading...

Loading...