B4-6 Fuel Tank B04026

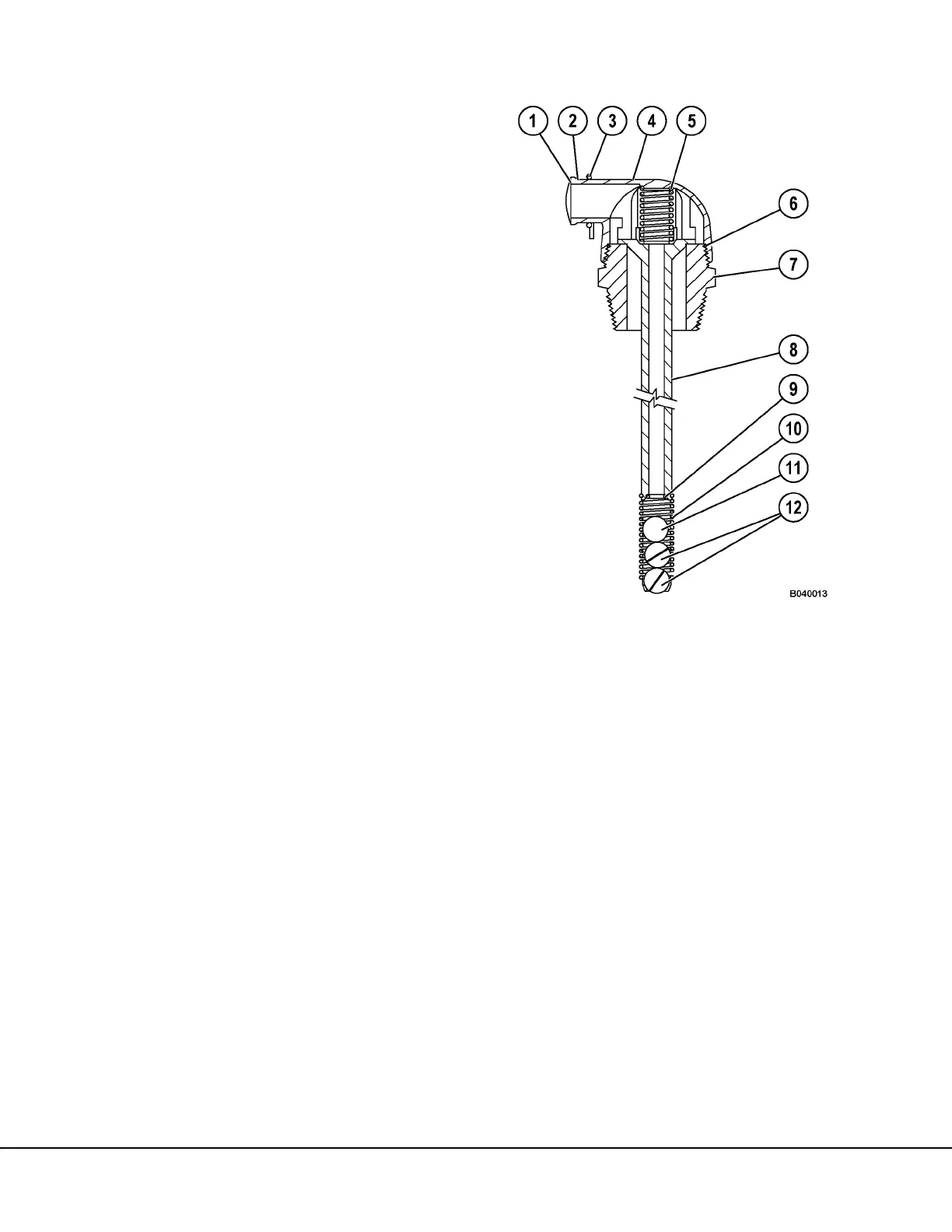

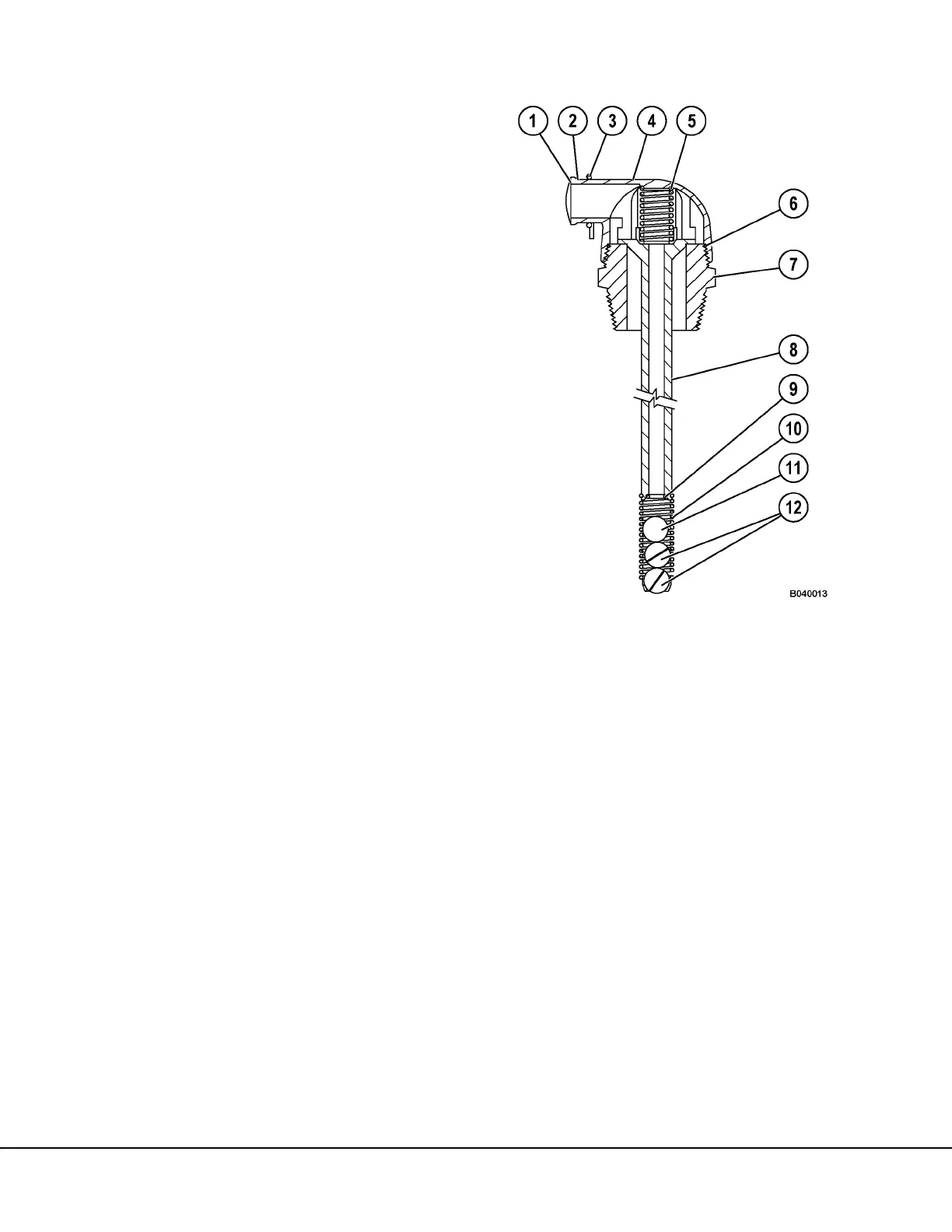

FUEL TANK BREATHER VALVE

NOTE: The relief pressure of the fuel tank breather

valve is 70 - 89 kPa (10 - 13 psi).

Disassembly

1. Remove clamp (3, Figure 4-2), cover (2) and

screen (1).

2. Remove ball cage (10), solid ball (11) and float

balls (12).

3. Unscrew end fitting (7) from body (4).

4. Remove stem (8) and valve spring (5).

Assembly

1. Clean and inspect all parts. If any parts are

damaged, replace the entire assembly.

2. Place valve spring (5) into position in body (4).

3. Insert stem (8) into end fitting (7).

4. Screw end fitting (7) into body (4). Ensure the

components are properly aligned and seated.

5. Place screen (1) and cover (2) into position on

the breather. Install clamp (3).

6. Insert the balls into ball cage (10) with solid ball

(11) on top.

7. Insert the ball cage onto the stem. A minimum

of two cage coils must be seated in the groove

on the stem. Ensure the solid ball is able to seat

properly on the stem. If not, adjust the cage

accordingly.

FUEL RECEIVERS (WIGGINS QUICK FILL)

Fuel receiver assembly (2, Figure 4-1) is mounted on

the side of the fuel tank.

Keep the cap on the fuel receiver to prevent dirt build

up in valve area and nozzle grooves.

If fuel spills from the fuel tank breather valve (7), or if

the tank does not completely fill, check the breather

valve to see whether the float balls are in place and

the outlet screen is clean. If the breather valve is

operating properly, the problem will most likely be in

the fuel supply system.

LOW FUEL SWITCH

Low fuel switch (13, Figure 4-1) controls the low fuel

level indicator on the overhead warning indicator light

panel in the operator cab. The switch is calibrated to

turn on the low fuel indicator when the usable fuel

remaining in the tank is approximately 25 gallons (95

liters).

FIGURE 4-2. BREATHER VALVE

1. Screen

2. Cover

3. Clamp

4. Body

5. Valve Spring

6. O-Ring

7. End Fitting

8. Stem

9. O-Ring

10. Ball Cage

11. Solid Ball

12. Float Ball

Loading...

Loading...