C04034 Power Train C4-7

Joining Alternator and Komatsu SSDA16V160 or

SDA16V160 Engine

When lifting alternator, attach hoist to lift eyes

only. The alternator weighs approximately 4037

kg (8,900 lbs). Use a lifting device that can handle

the load safely.

1. Use the two top lift brackets provided on the

alternator for lifting. The top front lifting bracket

should be equipped with some method of

adjusting the alternator to keep it horizontal.

2. Carefully move alternator into place and

engage the engine drive ring (6, Figure 4-7) into

the alternator rotor drive (7) using shims “B”, if

required (refer to step 5.a. “Determining

Shims”).

3. Install flywheel housing adapter cap screws (2)

into alternator housing (1). Tighten to 237 N·m

(175 ft lbs) torque.

4. Install cap screws (5) through engine drive ring

(6) into the alternator rotor adapter (7). Rotate

crankshaft to access and align holes. Tighten

cap screws (5) to 237 N·m (175 ft lbs) torque.

5. Install alternator-to-cradle structure mounting

cap screws and washers (1, Figure 4-2) and

tighten to 1017 N·m (750 ft lbs) torque.

6. Tighten engine-to-cradle structure mounting

cap screws (3, Figure 4-2) to 465 N·m (345 ft

lbs) torque.

Never pry on the engine crankshaft damper!

7. With magnetic base mounted on the front of the

engine and the dial indicator on the front of the

crankshaft, measure total crankshaft end-play:

Record Total Crankshaft End-play: ____________

8. Compare the step 7 value to the measurement

taken before alternator was installed on engine.

The total Engine Crankshaft End-play (step 7)

must equal the original measurement or 0.51 mm

(0.020 in.) (alternator end-play), whichever is

smaller. If the end-play after the alternator and

engine are assembled is less than 0.51 mm (0.020

in.), and less than the starting engine crankshaft

end-play, RESHIMMING IS REQUIRED.

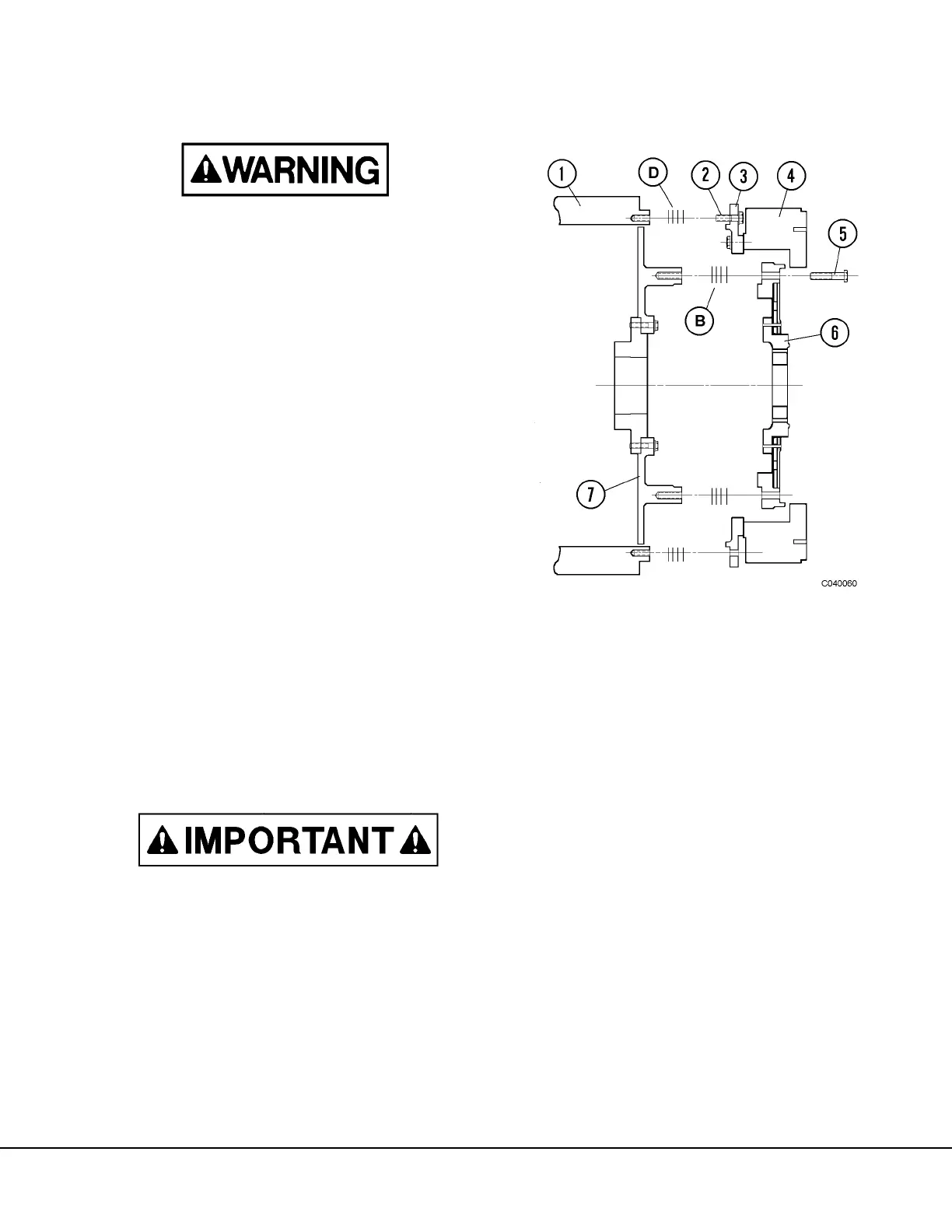

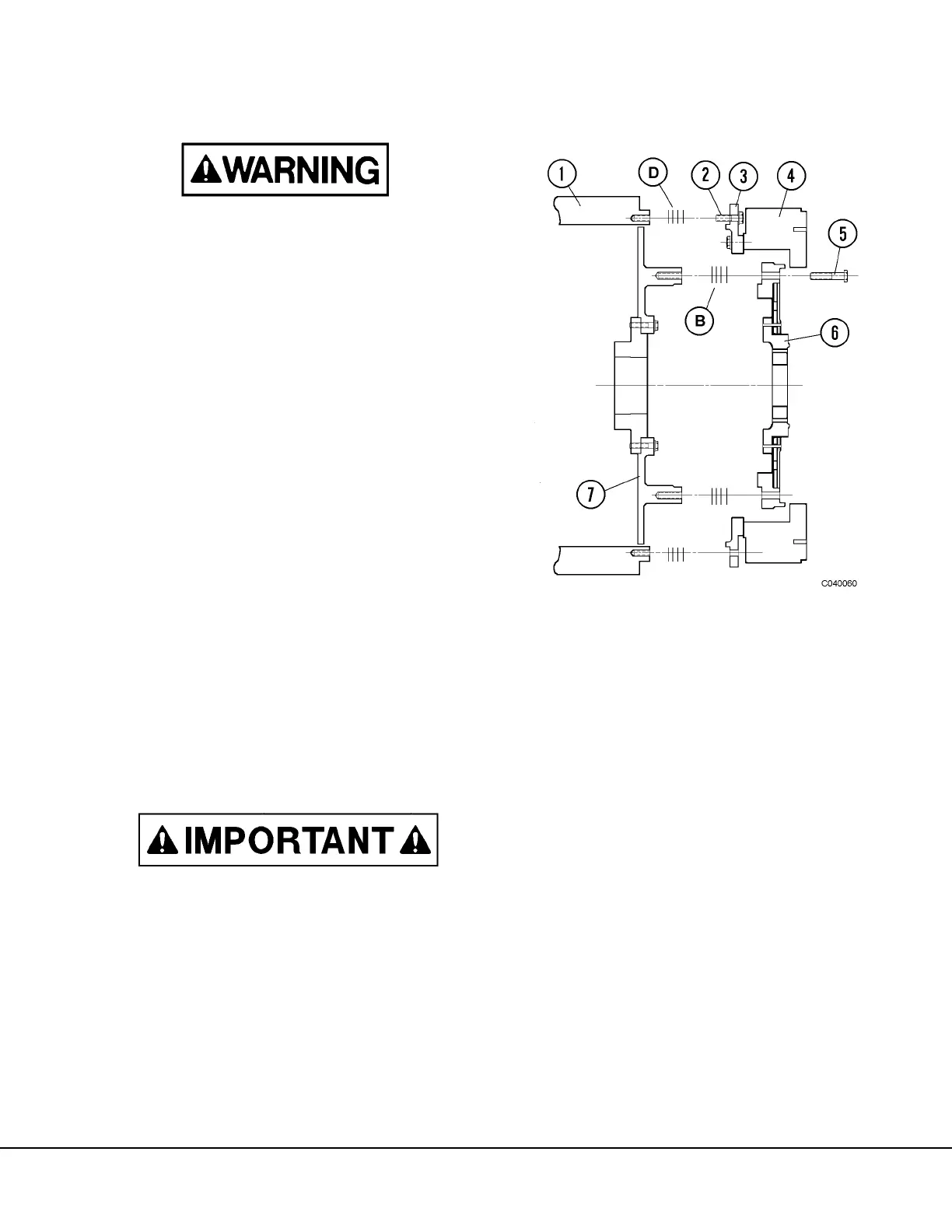

FIGURE 4-7. ALTERNATOR TO ENGINE

MOUNTING

1. Alternator Housing

2. Cap Screw

3. Flywheel Housing

Adapter

4. Engine Flywheel

Housing

5. Cap Screw

6. Engine Drive Ring

7. Alternator Rotor

“B” Drive Shims

“D” Housing Shims

Loading...

Loading...