.

OPERATION

EXPLANATION OF COMPONENTS

4. Manufacturing external power source input cable

The external power source input cable must be manufactured locally to match the local conditions. This does

not mean that any cable can be used.

Manufacture the cable as follows.

1)

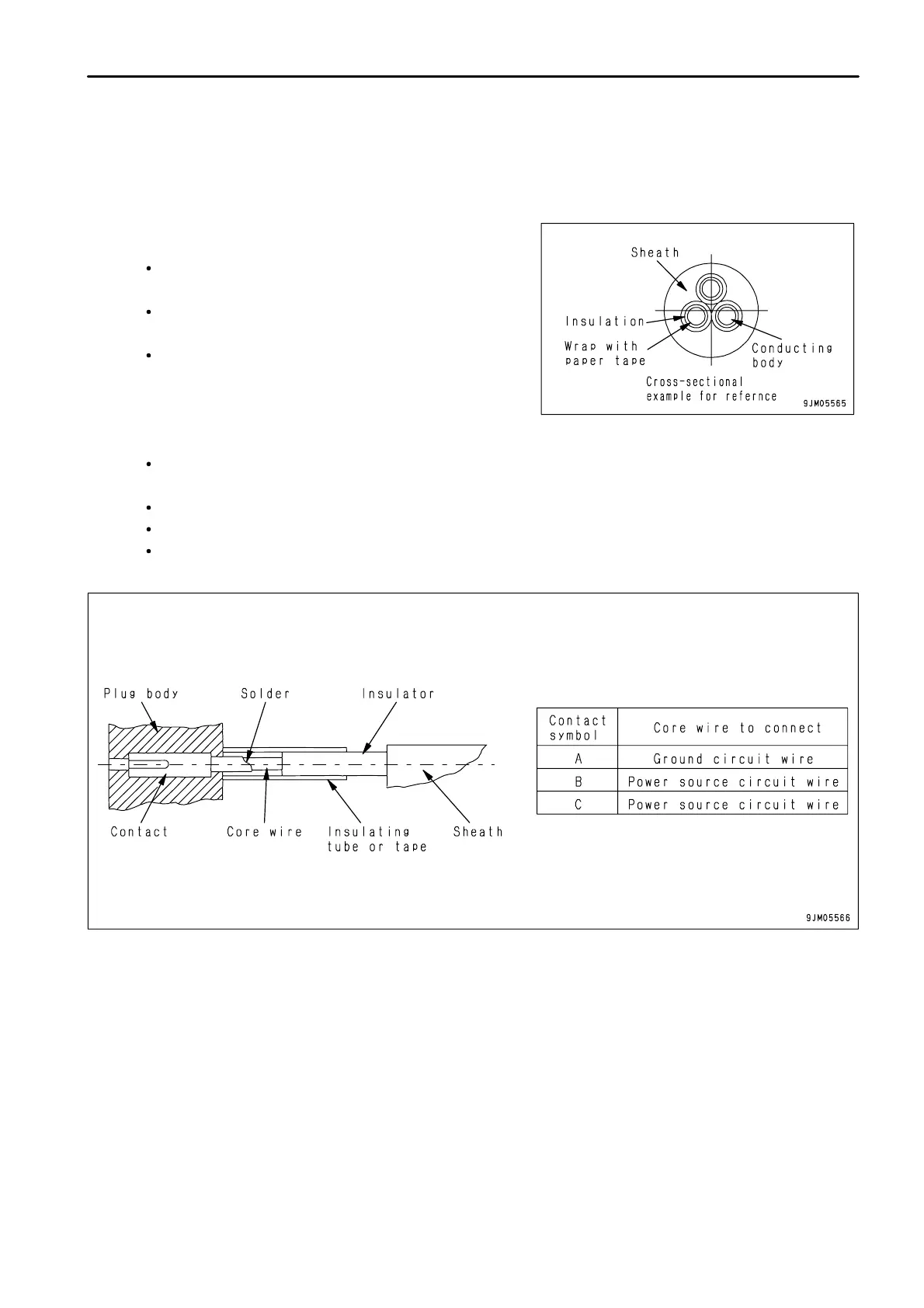

For the wiring, purchase three-core chloroprene sheath

cab tire cable locally.

The nominal cross-sectional area of one core should be

5 to 8 mm

2

.

For the voltage resistance function, it should be able to

withstand 3000 volts for 1 minute.

To prevent any drop in voltage, make the length less

than 30 m (98 ft 5 in).

2)

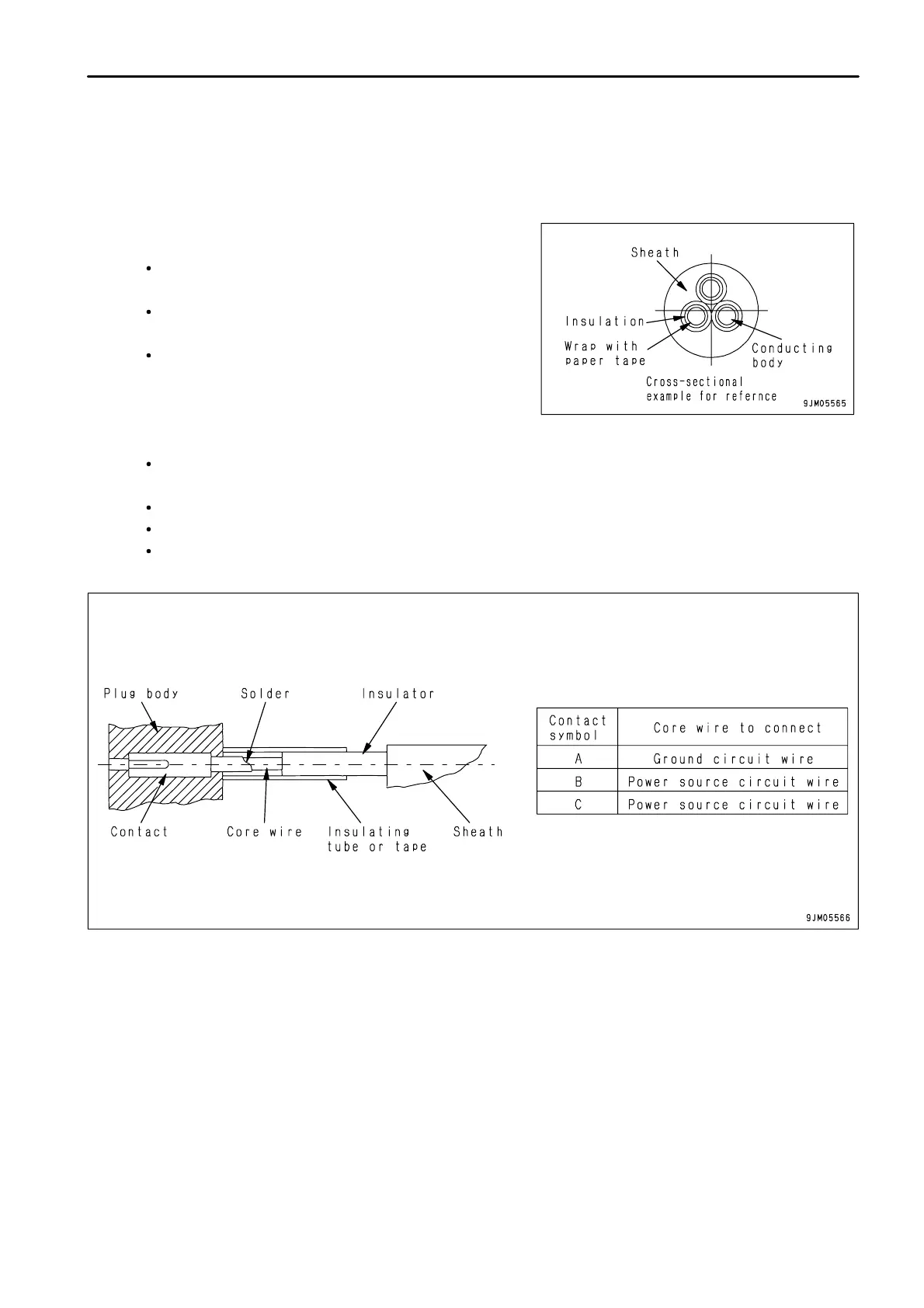

Connect the chassis input side plug (shipped as individual part) 175-06-37871 to the tip of the cable.

The plug has three contacts and each contact is marked with a symbol. Connect each of the 3 core wires

of the cable to its respective contact.

When connecting, solder each core wire to its contact.

To prevent short-circuiting through the conductor, insulate the soldered portion with a rubber tube or tape.

Always use part No. 175-06-37871 for the plug.

If any other plug is used, it will be impossible to connect to the external power input receptacle.

3 - 69

Loading...

Loading...