MAINTENANCE EVERY 10 OPERATING HOURS

7-31

MAINTENANCE EVERY 10 OPERATING HOURS

LUBRICATION

• There is danger of severe accidents, if you perform main-

tenance work at a machine that has not been parked and

secured correctly!

Park the machine on a solid, even surface and secure it,

before you start to perform maintenance work.

1. Before you start maintenance work, park and secure the

machine as described in the chapter "Prior to Start of Main-

tenance Measures".

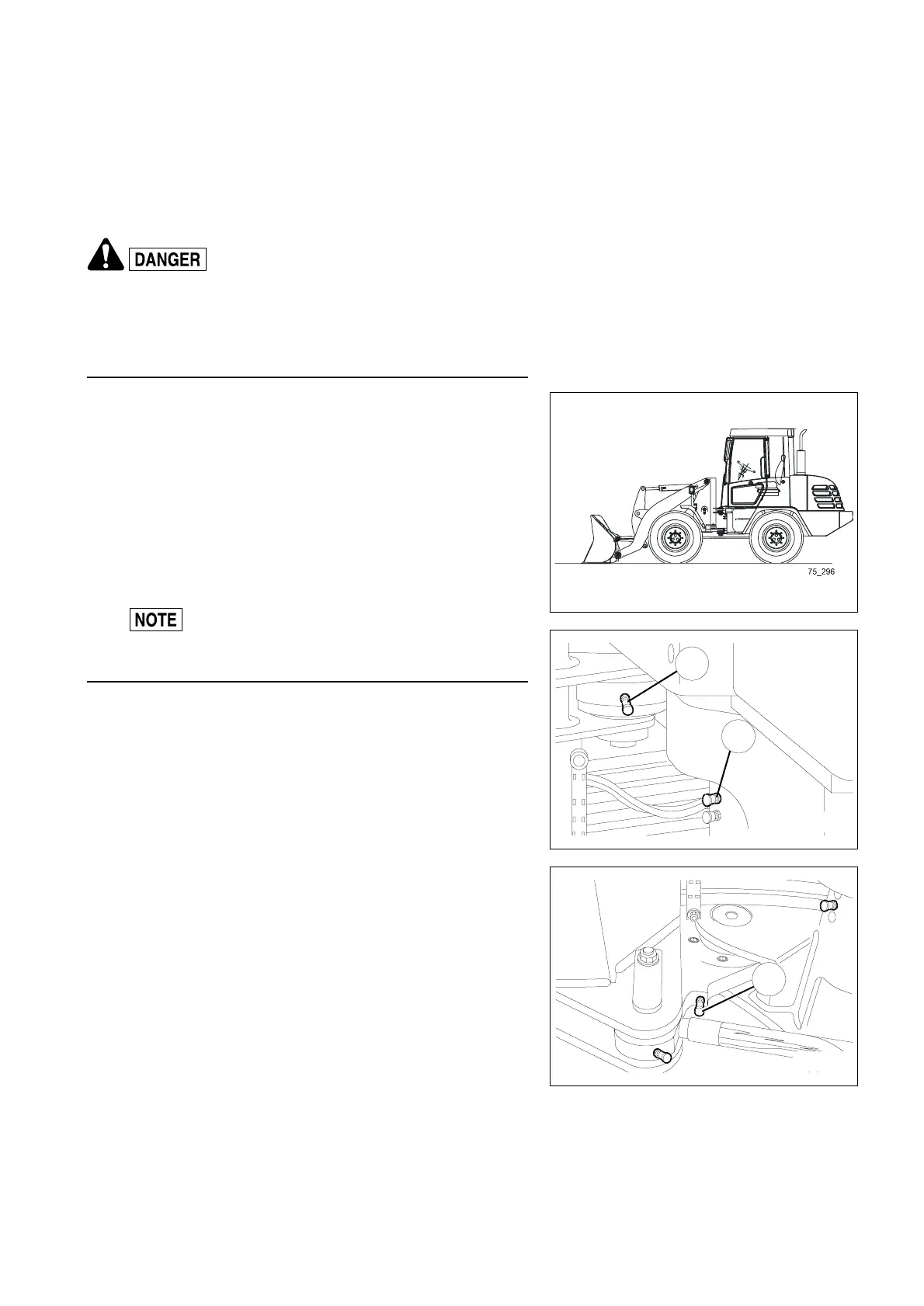

2. Clean the grease nipples marked by arrows.

3. Use a grease gun to fill the grease nipples with a sufficient

volume of lubricating grease.

Articulated steering (3 points)

4. Remove the used lubricating grease that is pressed out of

the bearings.

☞

• Perform lubrication more frequently, when working in a

continually wet or salty environment.

75_216

1

2

75_217

3

Loading...

Loading...