MAINTENANCE AFTER THE FIRST 50 OPERATING HOURS

7-38

TRANSFER GEAR - CHANGING OIL

• Frequent contact between used hydraulic oil and skin

may cause skin lesions and other physical damage!

Wear rubber gloves when changing the oil. Thoroughly

wash off any hydraulic oil adhering to your skin.

• Hot engine oil may cause scalding!

Wear rubber gloves and place the oil trough under the dis-

charge hole in such a way that you do not get in contact

with the oil when it is running out.

• There is danger of severe accidents, if you perform main-

tenance work at a machine that has not been parked and

secured correctly!

Park the machine on a solid, even surface and secure it,

before you start to perform maintenance work.

Have an oil trough with a sufficient capacity ready.

Perform an oil change with the gear unit at operating tempera-

ture.

1. Before you start maintenance work, park and secure the

machine as described in the chapter "Preparing the Ma-

chine for Maintenance".

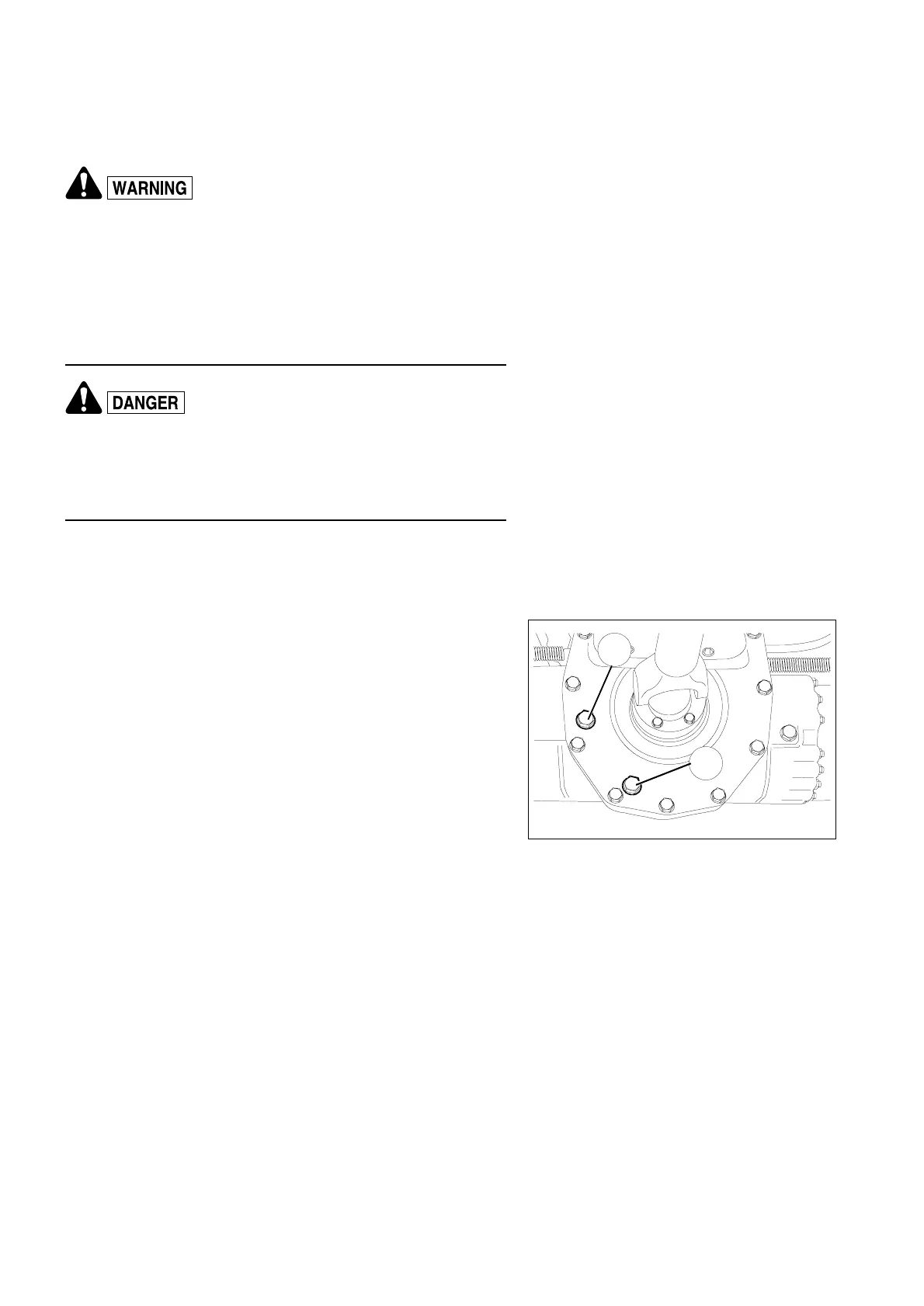

2. Clean the surfaces of the screw plugs (1) and (2) and the ar-

ea around the screw plugs.

3. Unscrew the screw plugs.

4. Let the oil flow off.

5. Clean the screw plugs and replace the gaskets.

6. Tightly screw in the screw plug (2).

7. Fill in oil via the check drill hole (1), until the oil reaches up to

the bottom edge of the check drill hole.

8. Tightly screw in the screw plug (1).

75_230

2

1

Loading...

Loading...