MAINTENANCE AFTER THE FIRST 50 OPERATING HOURS

7-34

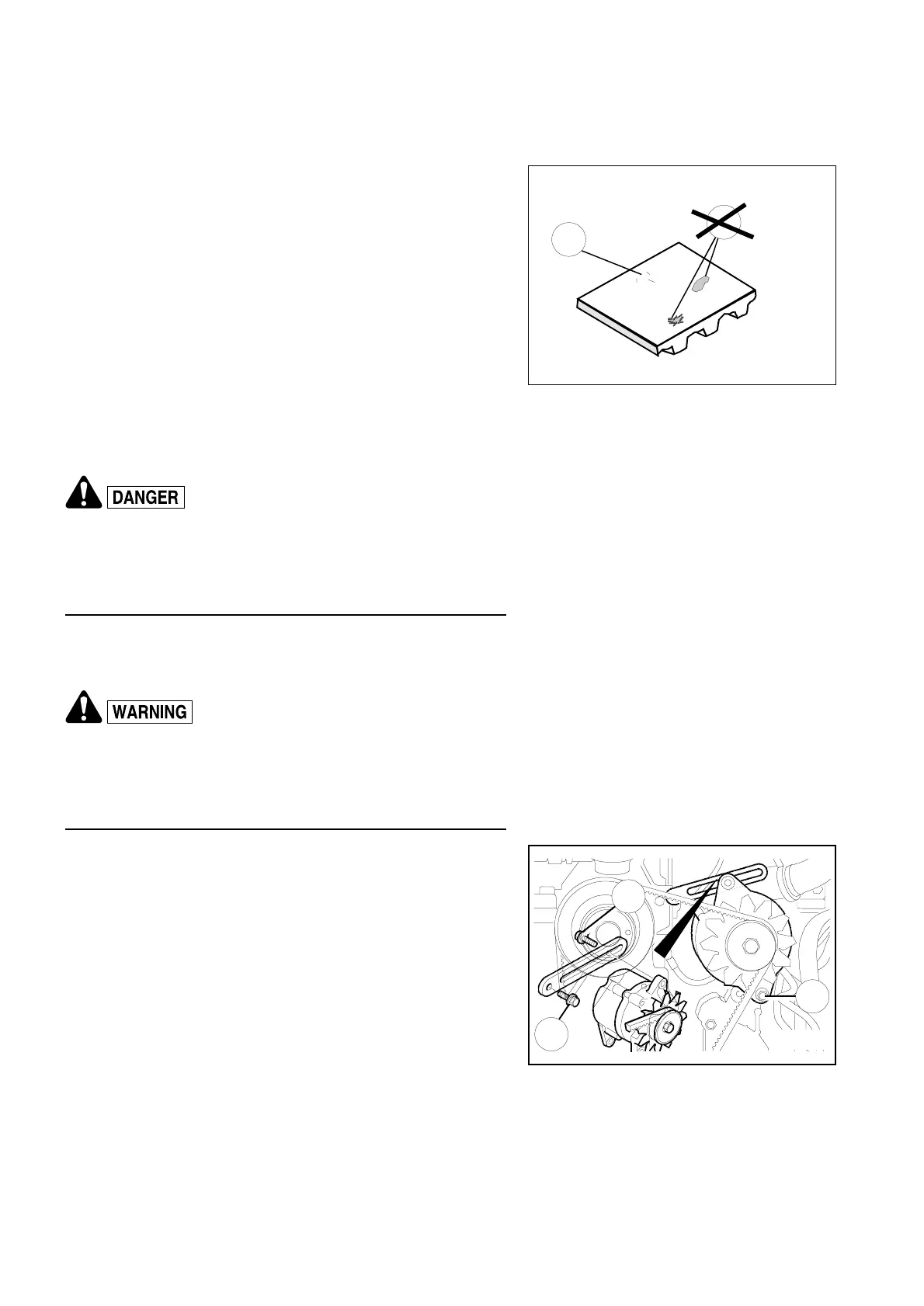

V-BELT, CHECKING THE CONDITION

Check the drive belt for fissures. Transversal fissures in direction

of the belt width are permitted. Longitudinal fissures in direction

of the belt length crossing transversal fissures, missing parts, or

damaged tissue layers are not permitted. In these cases, re-

place the drive belt.

V-BELT, CHECKING AND ADJUSTING THE TENSION

• There is danger of severe accidents, if you perform main-

tenance work at a machine that has not been parked and

secured correctly!

Park the machine on a solid, even surface and secure it,

before you start to perform maintenance work.

1. Before you start maintenance work, park and secure the

machine as described in the chapter "Preparing the Ma-

chine for Maintenance".

• Danger of injuries! When the engine is in operation, there

is danger of severe injuries by moving parts within the en-

gine compartment!

Do not work within the engine compartment, while the en-

gine is in operation.

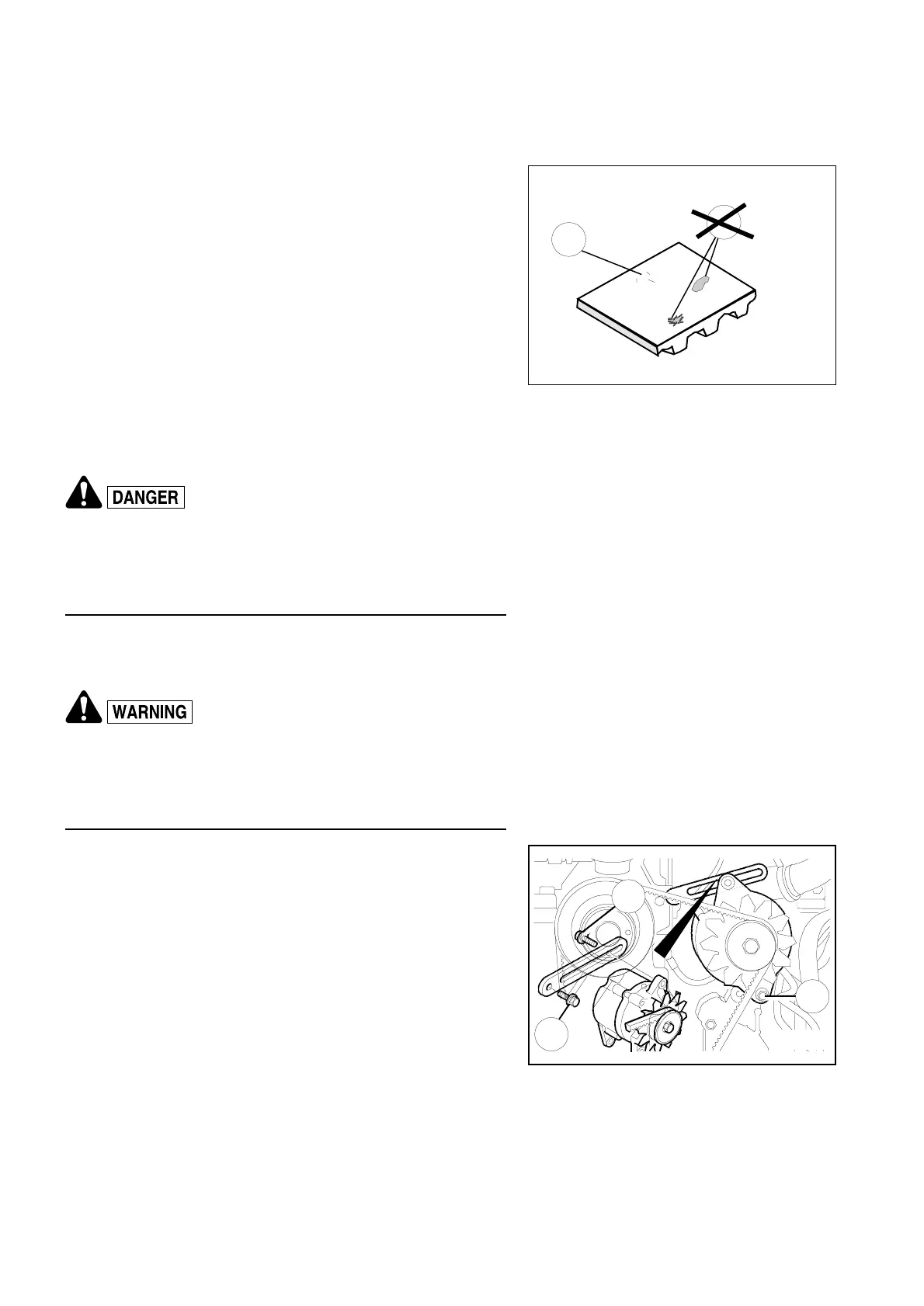

2. Press down the V-belt in the middle of the longest straight

part. You should be able to press the V-belt down about

0.394 in (10 mm) to 0.591 in (15 mm).

If you can press down the V-belt more than 0.394 in (10 mm)

to 0.591 in (15 mm), adjust the tension as follows:

3. Loosen the fastening screw (1) at the generator.

4. Loosen the connecting screw (2) between the generator and

the guide rail.

5. Loosen the fastening screw (3) at the guide rail.

6. Tilt the generator to adjust the tension of the V-belt.

7. Fasten the generator and the guide rail.

8. Check the tension of the V-belt and re-adjust it, if required.

75_219

OK

OK

2

3

75_220

1

Loading...

Loading...