MAINTENANCE EVERY 50 OPERATING HOURS

7-43

LUBRICATION

LUBRICATING POINTS OF THE WORK

EQUIPMENT

• If you perform maintenance operations at a machine

which is not properly parked and secured, severe acci-

dents may occur!

Park the machine on firm, level ground and secure it be-

fore starting the maintenance operations.

1. Park and secure machine for the maintenance operations as

described in chapter "Preparing the Machine for Mainte-

nance".

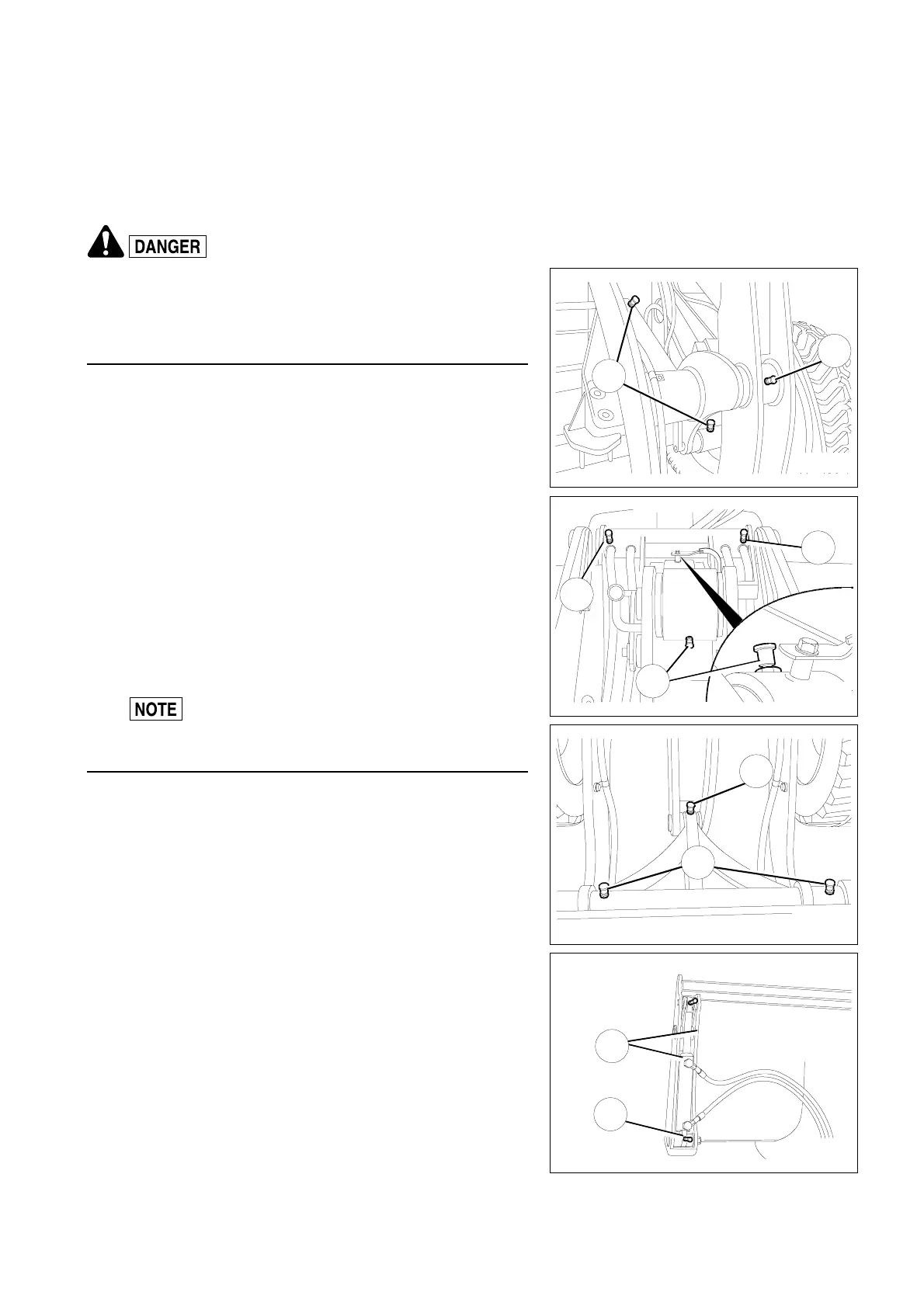

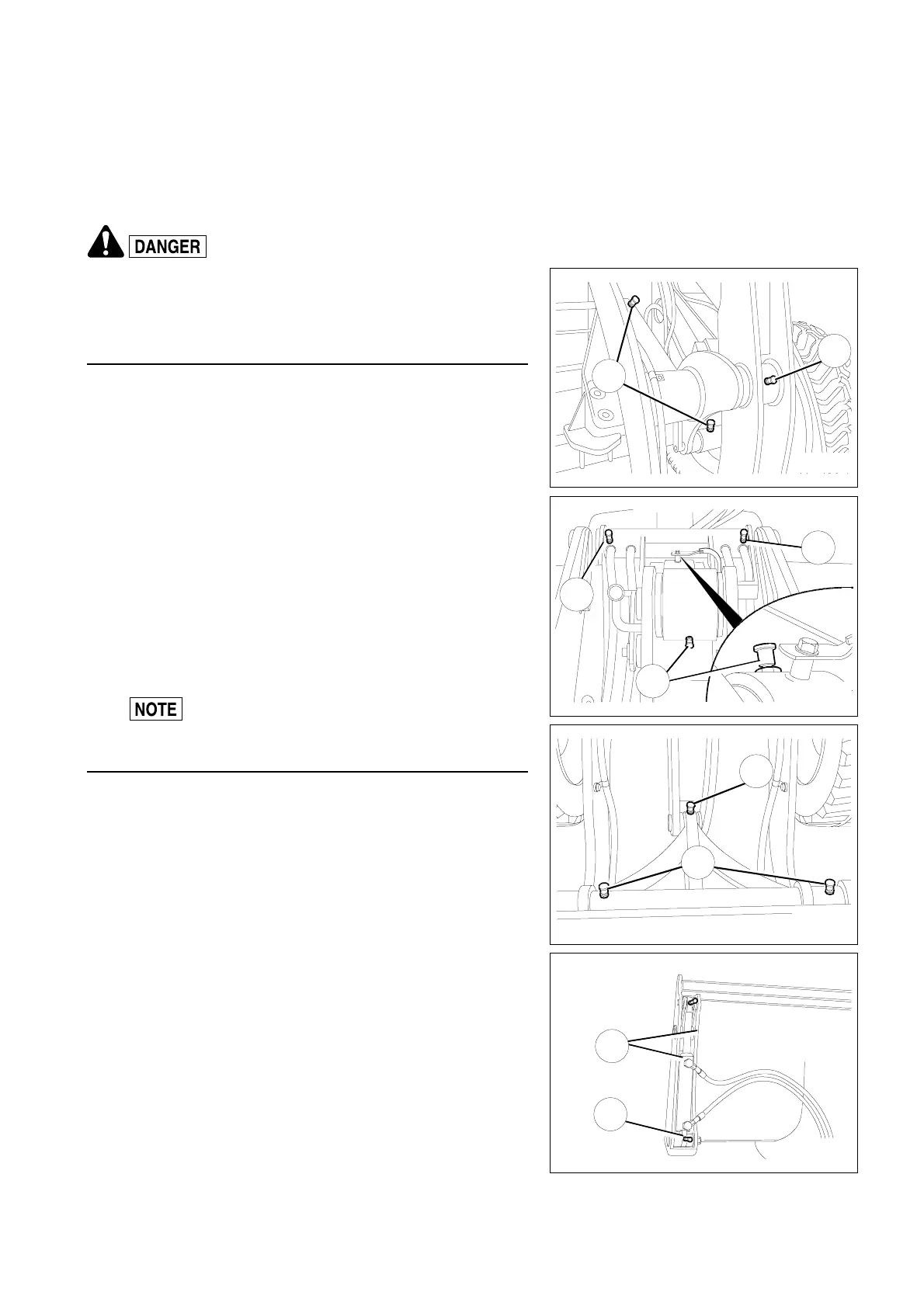

2. Clean the grease nipples which are indicated by the arrows.

3. Use a grease gun to press sufficient grease into the grease

nipples.

4. Remove the old grease which is extruding at the bearings.

☞

• If you operate in humid conditions or in a salty environ-

ment, you must reduce the lubricating intervals.

75_241

2

1

75_240

4

3

3

75_242

5

5

75_263

6

6

Lifting cylinder (1) (2 locations)

Rocker arm (2) (1 location)

Boom (3) (2 locations)

Tipping cylinder (4) (2 locations)

Quick-change unit (5) (3 locations)

Clamshell bucket (6) (3 locations)

Loading...

Loading...