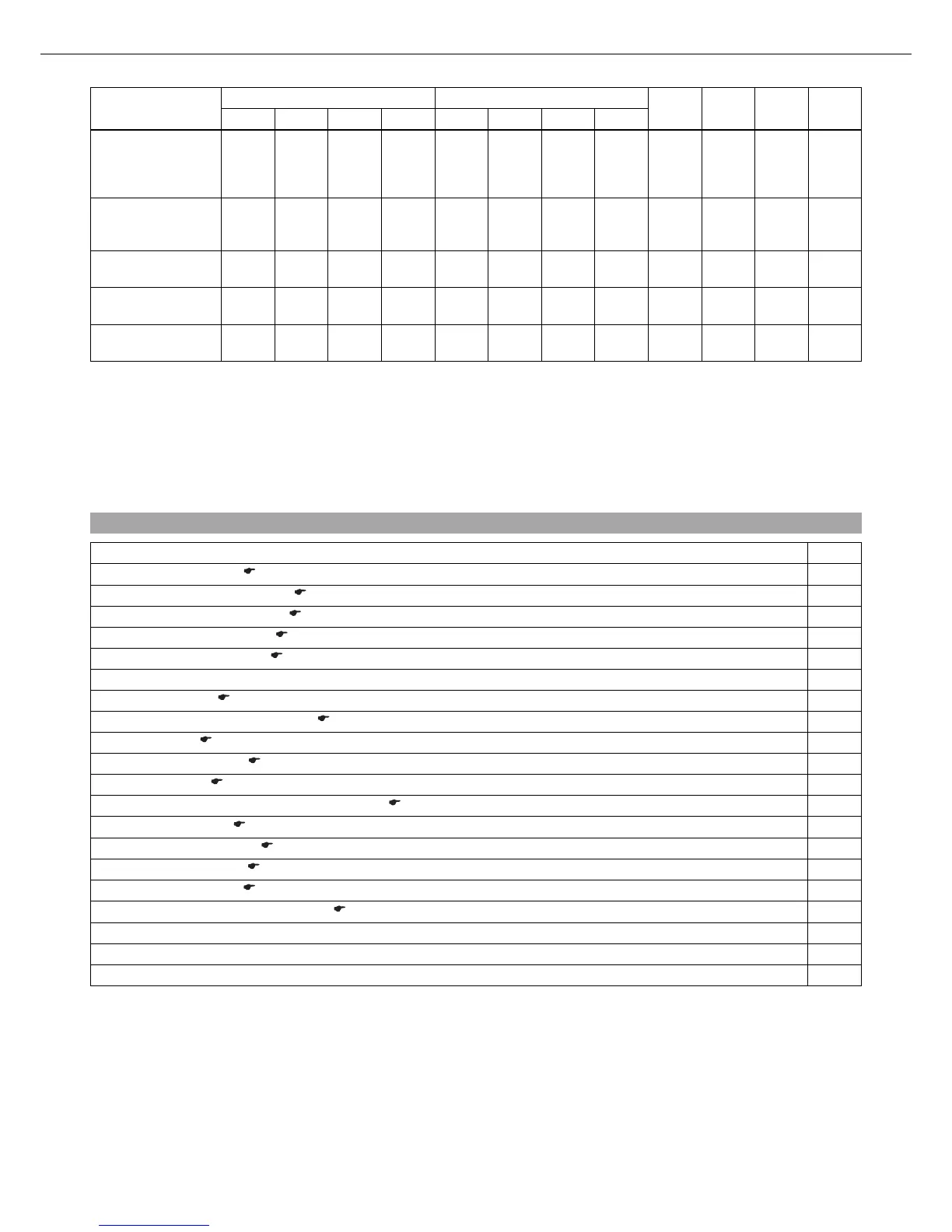

SERVICE SCHEDULE 37

Competition use Hobby use S10A S20N S30A J1A

S10A S20A S40A S80A S20A S40A S60A S80A

Check exhaust con-

trol for functioning

and smooth opera-

tion, clean. x

• • • • • • • •

Change the

crankshaft main

bearing. x

• •

Change the conrod

bearing. x

• • •

Check the transmis-

sion. x

• • •

Check the shift

mechanism. x

• • •

S10A: every 10 operating hours

S40A: every 40 operating hours

S20A: every 20 operating hours

S60A: every 60 operating hours

S80A: every 80 operating hours

S20N: once after 20 operating hours

S30A: every 30 operating hours

J1A: annually

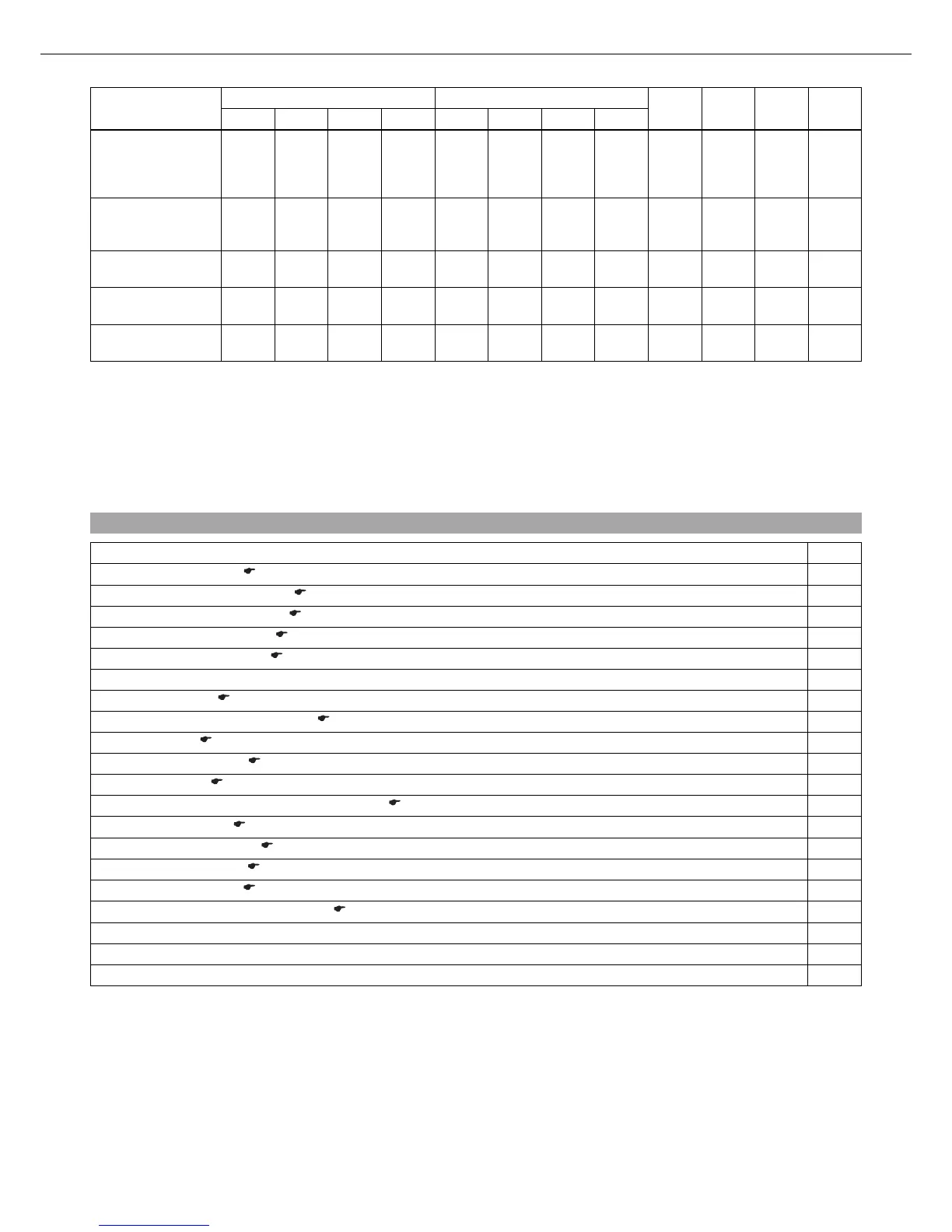

10.3Important checks and maintenance work to be carried out by the rider

NB1A

Check the gear oil level. ( p. 88) •

Check the front brake fluid level. ( p. 59) •

Check the rear brake fluid level. ( p. 63) •

Check the front brake linings. ( p. 60) •

Check the rear brake linings. ( p. 64) •

Check and adjust the cables. •

Bleed the fork legs. ( p. 47) •

Clean the dust boots of the fork legs. ( p. 47) •

Clean the chain. ( p. 54) •

Check the chain tension. ( p. 55) •

Check chain wear. ( p. 55) •

Check the rear sprocket/engine sprocket for wear. ( p. 55) •

Clean the air filter. x ( p. 82)

•

Check the tire air pressure. ( p. 70) •

Check the tire condition. ( p. 69) •

Check the coolant level. ( p. 77) •

Empty the carburetor float chamber. x ( p. 87)

•

Check all controls for smooth operation. •

Check braking. •

Check all screws, nuts and hose clamps regularly for tightness. •

NB1A: Depending on conditions of use according to requirements.

Loading...

Loading...