BOOM 14000 SERVICE MANUAL

4-10

Published 09-05-14, Control # 226-02

Corrosion or Abrasion

See Figure 4-11 for following procedure.

For quick identification by repair workers, clearly mark

damaged areas with brightly colored tape.

1. Sandblast to remove corrosion. Do not grind.

2. Determine reduction in thickness.

3. If reduction is less than 6% of strap thickness, paint

strap to maintain continuous protective coating.

4. If reduction is 6% or more, remove strap from service.

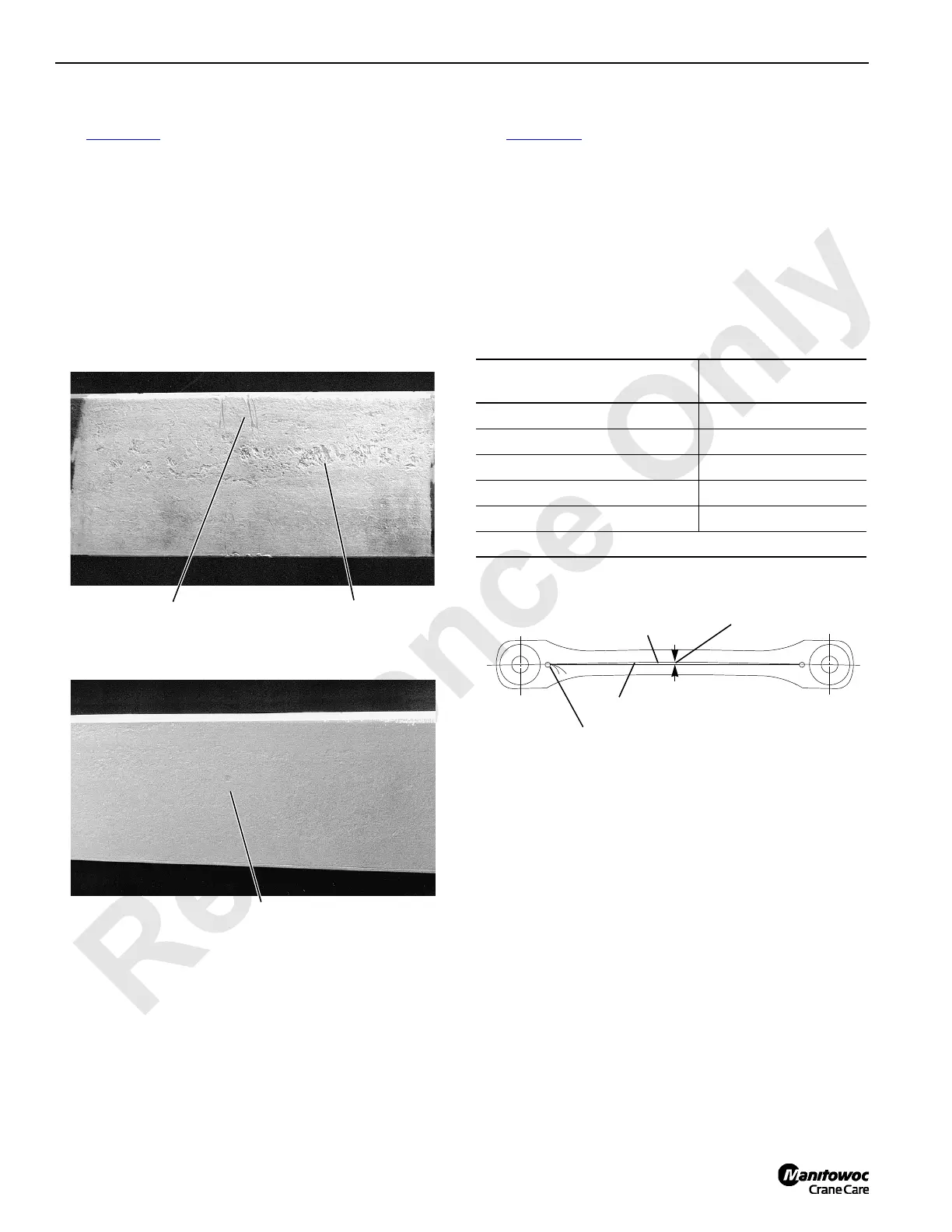

Straightness

See Figure 4-12 for following procedure.

1. Stretch a line (string or wire) from pin storage hole at one

end of strap.

2. Stretch line as tight as possible and tie it off at other end.

3. Mark strap center line. Do not use center punch.

4. If string does not align with center line, measure

distance from center line to line.

If deviation from straight is greater than maximum allowed,

remove strap from service.

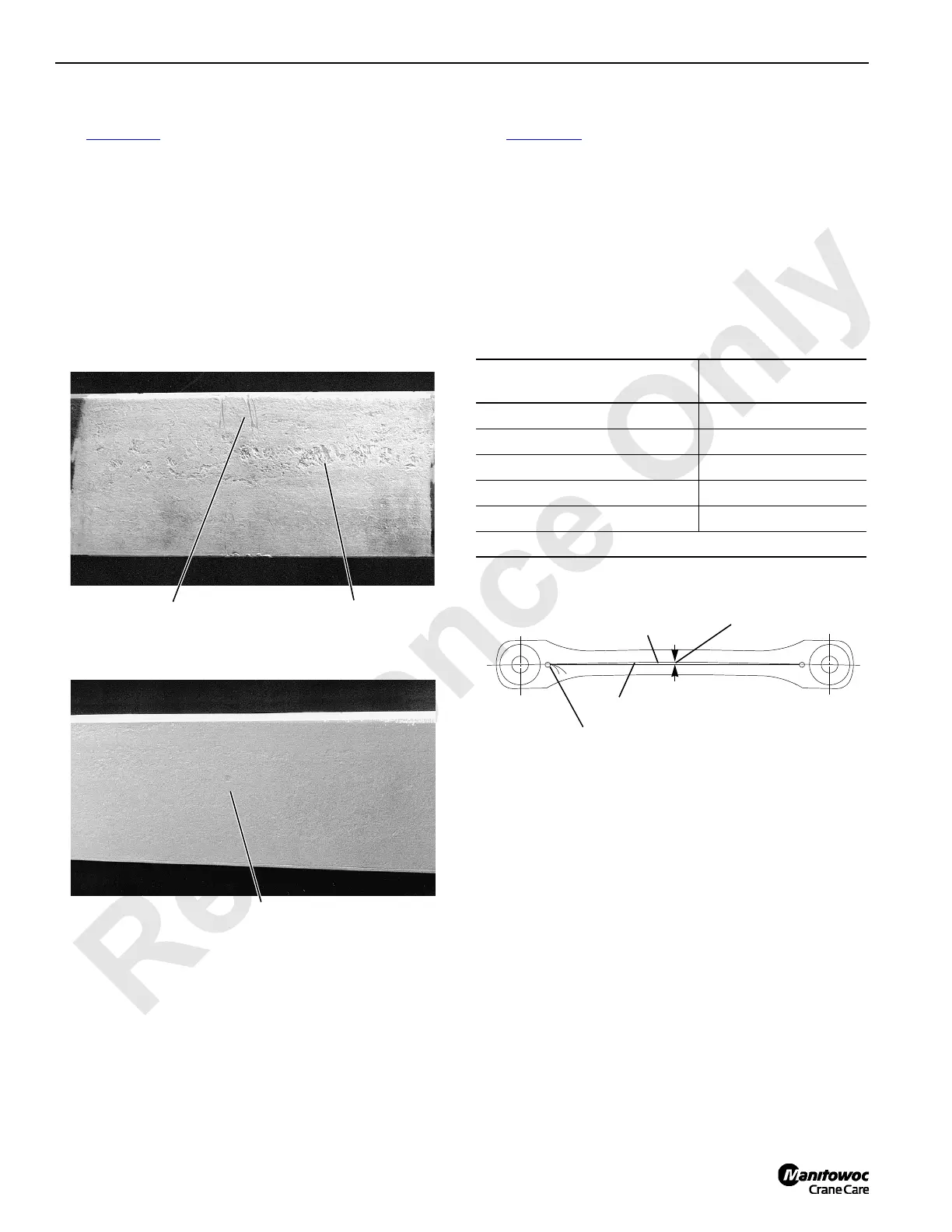

Not Acceptable

Abrasion from handling

with chain exceeds allowable limit.

Acceptable

Surface is relatively smooth; within allowable limit.

Not Acceptable

Surface is badly pitted;

exceeds allowable limit.

P325

P326

FIGURE 4-11

Corrosion or Abrasion

Strap Length

(L)

Maximum Deviation

Allowed

5 to <10 ft (1.5 to <3.0 m) 0.060 in (1.5 mm)

10 to <20 ft (3.0 to <6.1 m) 0.125 in (3.2 mm)

20 to <30 ft (6.1 to <9.1 m) 0.125 in (6.4 mm)

30 to <40 ft (9.1 to <12.2 m) 0.375 in (9.5 mm)

40 to <50 ft (12.2 to <15.2 m) 0.50 in (12.7 mm)

< = less than

FIGURE 4-12

Pin Storage

Hole (typical)

Center line

String

Deviation

from Straight

A1086

Straightness (gradual

or sweeping bend)

Loading...

Loading...