Manitowoc Published 09-05-14, Control # 226-02 4-11

14000 SERVICE MANUAL BOOM

Flatness

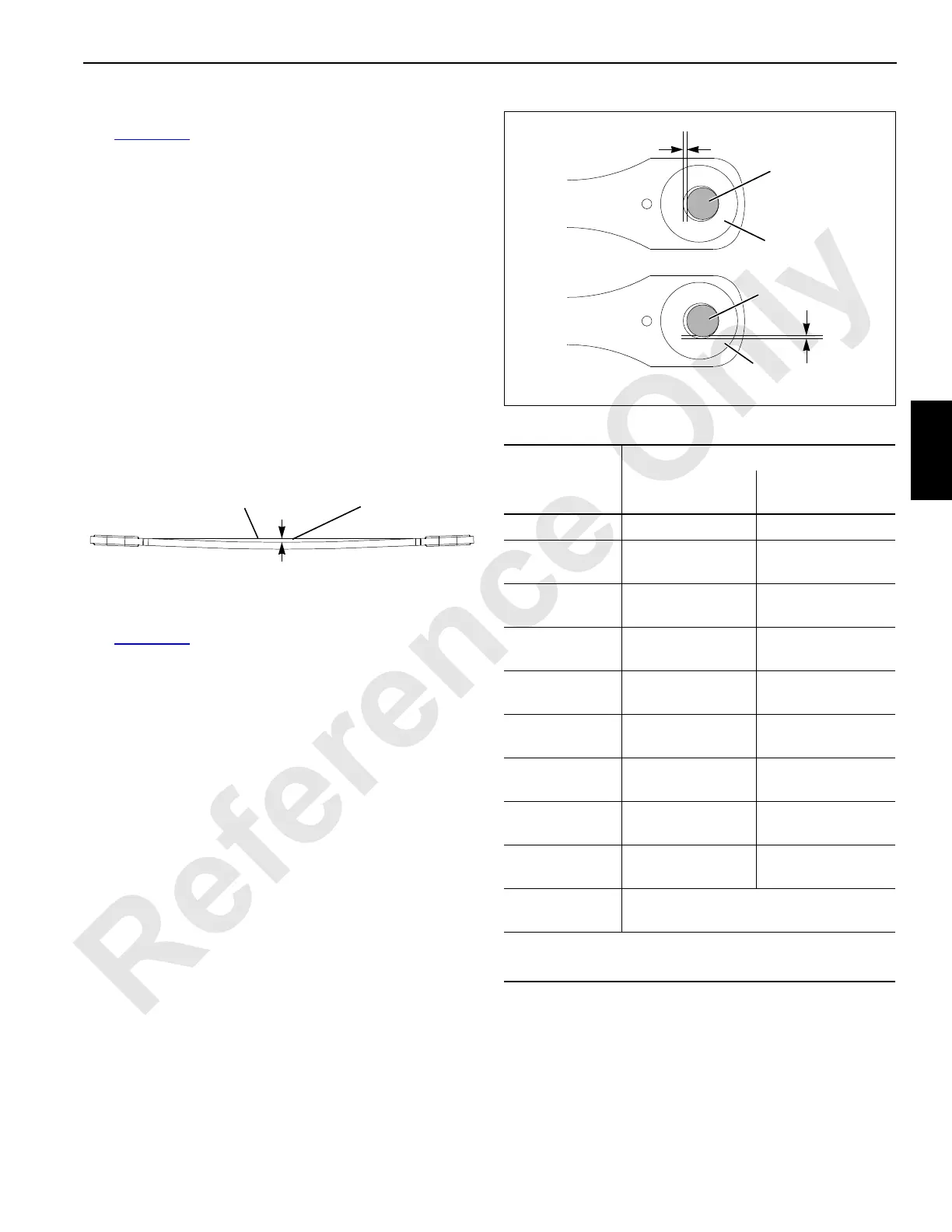

See Figure 4-13 for following procedure.

1. Lay strap on a flat surface. Do not block; strap may

sag

2. Stretch a line (string or wire) across top surface of strap

from pin storage hole at one end of strap.

3. Stretch line as tight as possible and tie it off at other end.

4. Check that line touches top surface of strap at all points

along its length.

5. If string does not touch strap, measure distance from

line to strap.

If deviation from straight is greater than maximum

allowed, remove strap from service.

6. Remove line. Turn strap over.

7. Repeat steps 1-5 above.

Elongated Hole

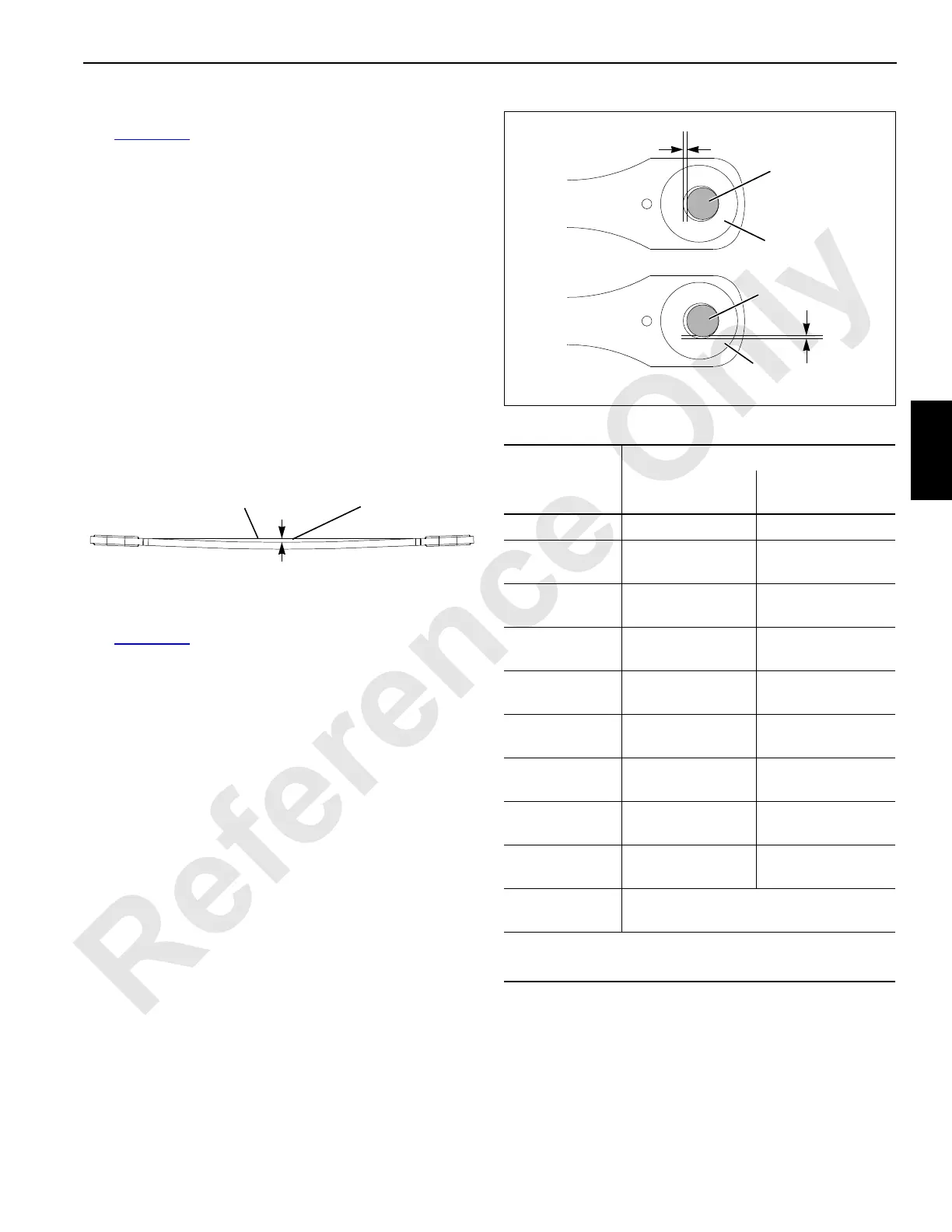

See Figure 4-14 for following procedure.

1. Insert pin into hole.

2. Push pin tight against edge of hole along horizontal

center line. Measure dimension between pin and hole

(View A).

3. Push pin tight against edge of hole along vertical center

line. Measure dimension between pin and hole (View B).

If dimensions A and B are not identical, hole is

elongated. Remove strap from service.

If two dimensions are identical, but greater than 0.030 in

(0,8 mm), contact the Manitowoc Crane Care Lattice

Team.

FIGURE 4-13

Distance between

Line and Strap

Line

A1086

Flatness (includes twisted straps)

Strap Length

(L)

ft (m)

Maximum Deviation Allowed

1 to <2 in (25.4 to

<50.8 mm) Thick

2 to <4 in (50.8 to

<101.6 mm) Thick

<3 (<0.9) 0.17 (4.3) 0.50 (12.7)

3 to <4

(0.9 to <1.2)

0.63 (15.9) 0.56 (14.3)

4 to <5

(1.2 to <1.5)

0.75 (19.1) 0.70 (17.5)

5 to <6

(1.5 to <1.8)

0.80 (20.6) 0.75 (19.1)

6 to <7

(1.8 to <2.1)

0.88 (22.2) 0.75 (19.1)

7 to <8

(2.1 to <2.4)

0.94 (23.8) 0.75 (19.1)

8 to <9

(2.4 to <2.7)

1.0 (25.4) 0.75 (19.1)

9 to <10

(2.7 to <3.0)

1.0 (25.4) 0.88 (22.2)

10 to <12

(3.0 to <3.7)

1.0 (25.4) 1.0 (25.4)

≥12 (≥3.7)

Deviation not to exceed 1 in (25.4 mm)

in any 12 ft (3.7 m) length of strap

< = less than

≥ = equal to or greater than

Pin

Strap

Pin

Strap

B

View A

View B

A

A1086

FIGURE 4-14

Elongated Holes

Loading...

Loading...