Manitowoc Published 09-05-14, Control # 226-02 7-3

14000 SERVICE MANUAL POWER TRAIN

Troubleshooting—Slow Cranking

If the starter cranks too slowly and the battery is charged and

in good condition, do a voltage-drop test to make sure the

starter connections are good.

When cranking, a voltage drop of more than 0.2 volts

between the starting motor cable and ground can cause hard

starting regardless of a battery’s condition. The voltage drop

can be caused by a poor contact between the cable terminal

and ground or between the clamp terminal and the battery

post. Poor start-switch contacts and frayed, broken, or

corroded cables can also be the cause.

Quarterly Battery Maintenance

• Thoroughly clean the batteries and the holder with a

baking soda/water solution.

• If provided, make sure the drain holes are open in the

holder. If water collects in the holder, drill drain holes.

• Clean the posts and terminals. Lightly coat the posts

with petroleum jelly to prevent corrosion.

• Replace frayed, broken, or corroded cables.

• Replace the batteries if their containers are cracked or

worn to the point they leak.

• Ensure a good tight contact between the clamp

terminals and battery posts.

• Make sure the hold-downs are tight enough to prevent

battery movement but not so tight to cause distortion.

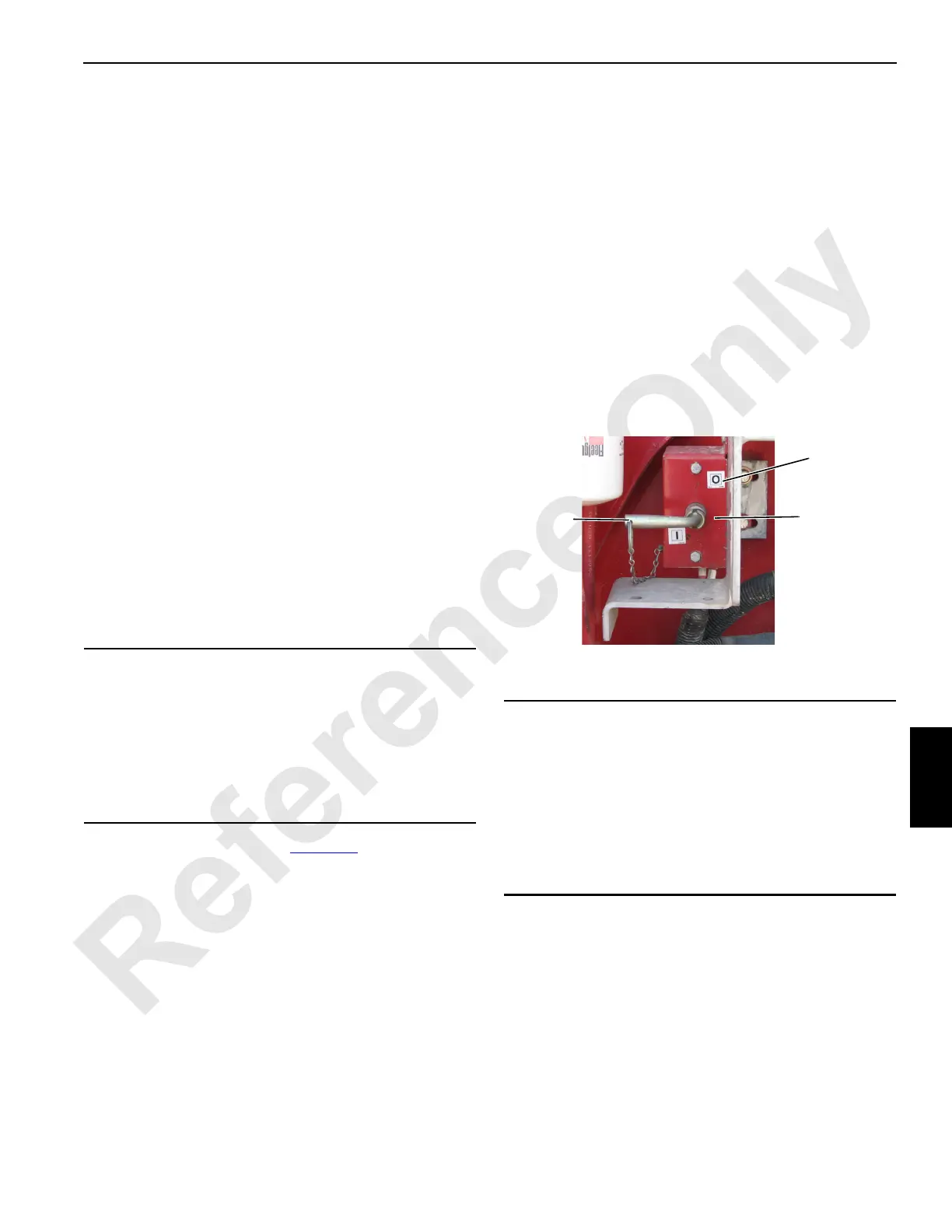

BATTERY DISCONNECT SWITCH

The battery disconnect switch (Figure 7-3) is located on the

right side next to the engine controller box.

The switch disconnects the engine controller (Node 0) from

the positive side of the battery. Since the rest of the crane’s

control system is powered through Node 0, opening the

disconnect switch effectively removes power from the entire

control system.

To operate the battery disconnect switch:

• Turn handle COUNTERCLOCKWISE to DISCONNECT

the control system to the battery (handle horizontal/

removable).

• Turn handle CLOCKWISE to CONNECT the control

system from the battery (handle vertical).

The following are reasons for using the disconnect switch:

• When servicing crane’s electrical control system.

• To help prevent batteries from discharging when the

crane is stored for extended periods of time.

• To prevent crane from being started by unauthorized

personnel.

CAUTION

Engine Damage

To avoid possible engine fault codes and undesirable

operation, make sure engine ignition switch has been off

five minutes before disconnecting batteries.

Do not rely on this switch to protect crane’s electronic

systems when welding. Disconnect battery cables at

batteries before welding.

CAUTION

Potential Control System Damage

Before Welding:

• Disconnect battery cables at batteries.

• Disconnect the cabling from any control node

enclosures that are in the vicinity of the welding.

Do not rely on the disconnect switch to protect the crane’s

electronic systems when welding.

FIGURE 7-3

Right Side of

Rotating Bed

Battery

Disconnect

Switch

Enable

Disable

M100785

Loading...

Loading...