Torque Requirements for Fasteners

PELLERIN MILNOR CORPORATION

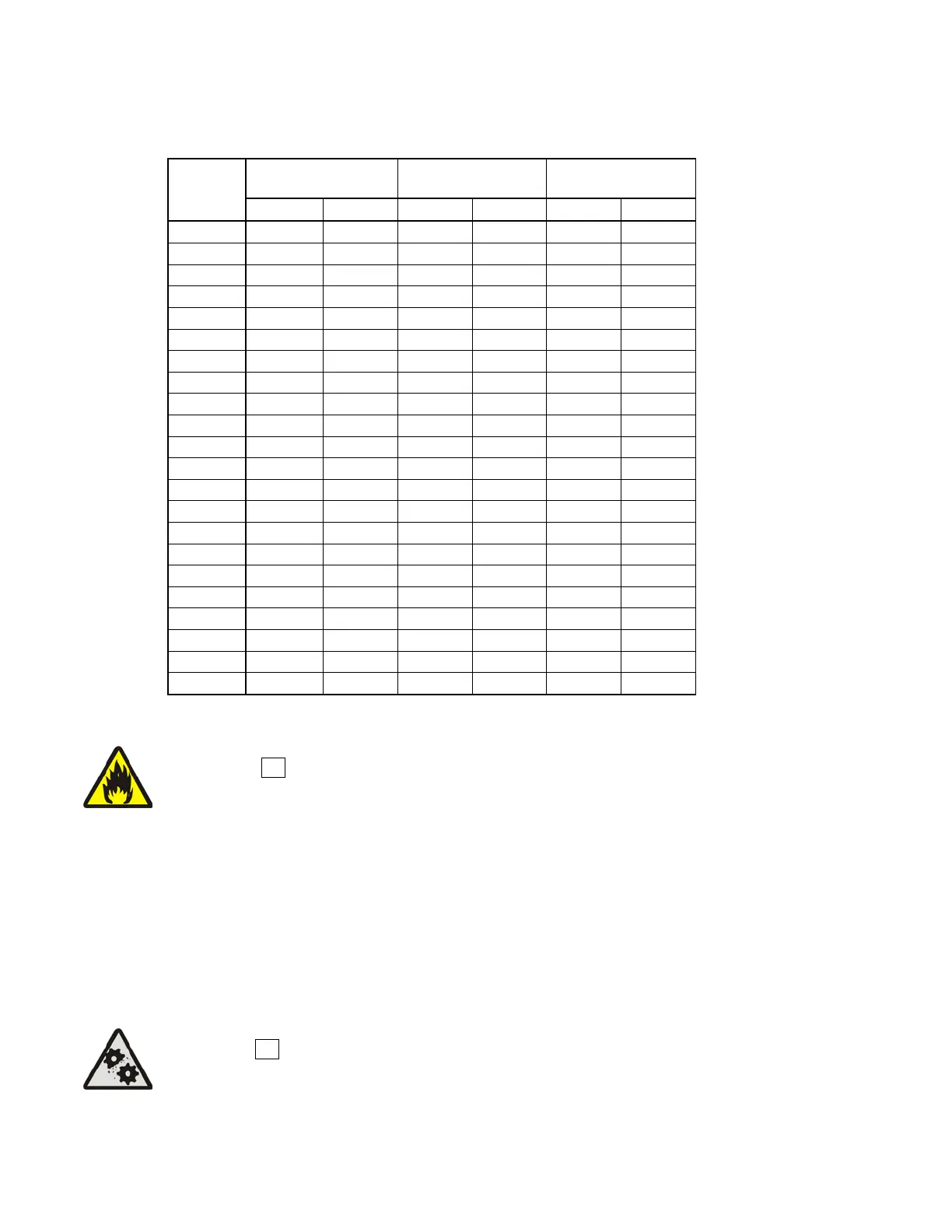

Table 12: Torque Values for Stainless Steel Fasteners Larger Than 5/16-inch

Dimension

316 Stainless

18-8 Stainless

18-8 Stainless with

Loctite 767

3/8 x 16

21

28

20

27

12

16

23

31

22

29

13

18

7/16 x 20

35

47

33

45

20

27

1/2 x 13

45

61

43

58

26

35

1/2 x 20

47

64

45

61

27

37

59

81

57

77

34

46

5/8 x 11

97

131

93

125

56

75

5/8 x 18

108

150

104

141

62

84

3/4 x 10

132

179

128

173

77

104

130

176

124

168

75

101

7/8 x 14

202

273

193

262

116

157

1 x 8

300

406

287

389

172

233

1 x 14

271

367

259

351

156

211

432

586

413

560

248

336

1-1/4 x 7

546

740

523

709

314

425

1-1/4 x 12

504

683

480

651

288

390

1-1/2 x 6

930

1261

888

1204

533

722

732

992

703

953

422

572

2 : Fire Hazard—Some solvents and primers are flammable.

Use threadlocker and primers with sufficient airflow.

Do not use flammable material near ignition sources.

1. Clean all threads with a wire brush or a different tool.

2. Remove the grease from the fasteners and the mating threads with solvent. Make the parts

dry.

Note 3: LocTite 7649 Primer

™

or standard solvents will remove grease from parts.

3. Apply a spray of LocTite 7649 Primer

™

or equal on the fasteners and the mating threads. Let

the primer dry for one minute minimum.

How to Apply a Threadlocker

3 : Malfunction Hazard—Heat, vibration, or mechanical shocks can let the

fasteners loosen if you do not apply the threadlocker correctly. Loose fasteners can cause

malfunctions of the equipment.

Read the threadlocker manufacturer's instructions and warnings. Obey these instructions.

37

Loading...

Loading...