2202L5JE-DA-C5-N_2015.05.

5 Maintenance and Inspection

Compound 2-stage Screw Compressor 5.5 Reassembly

1612LSC Speed Increaser Type

5-61

5.5.10 Installation of Speed Increaser Gear Casing to Low-stage

Bearing Head

a)

Start this operation after checking the bearing head assembly for the following point:

The bearing head has two oil holes, one for lubricating the speed increaser gear and the other for

lubricating the roller bearing of the speed increaser gear spindle. As each of the oil holes has the oil

flow control throttle [196-2] screwed inside, check that the throttle is not clogged.

b)

Apply oil to both sides of the speed increaser gear casing gasket [170] and attach it.

Carefully install the speed increaser gear casing gasket [170] with its sides

directed correctly. The gasket has an oil hole for the side bearing in the speed

increaser gear casing on one side, although the gasket is symmetrically shaped

and the bolt holes in it are also symmetrically arranged.

c)

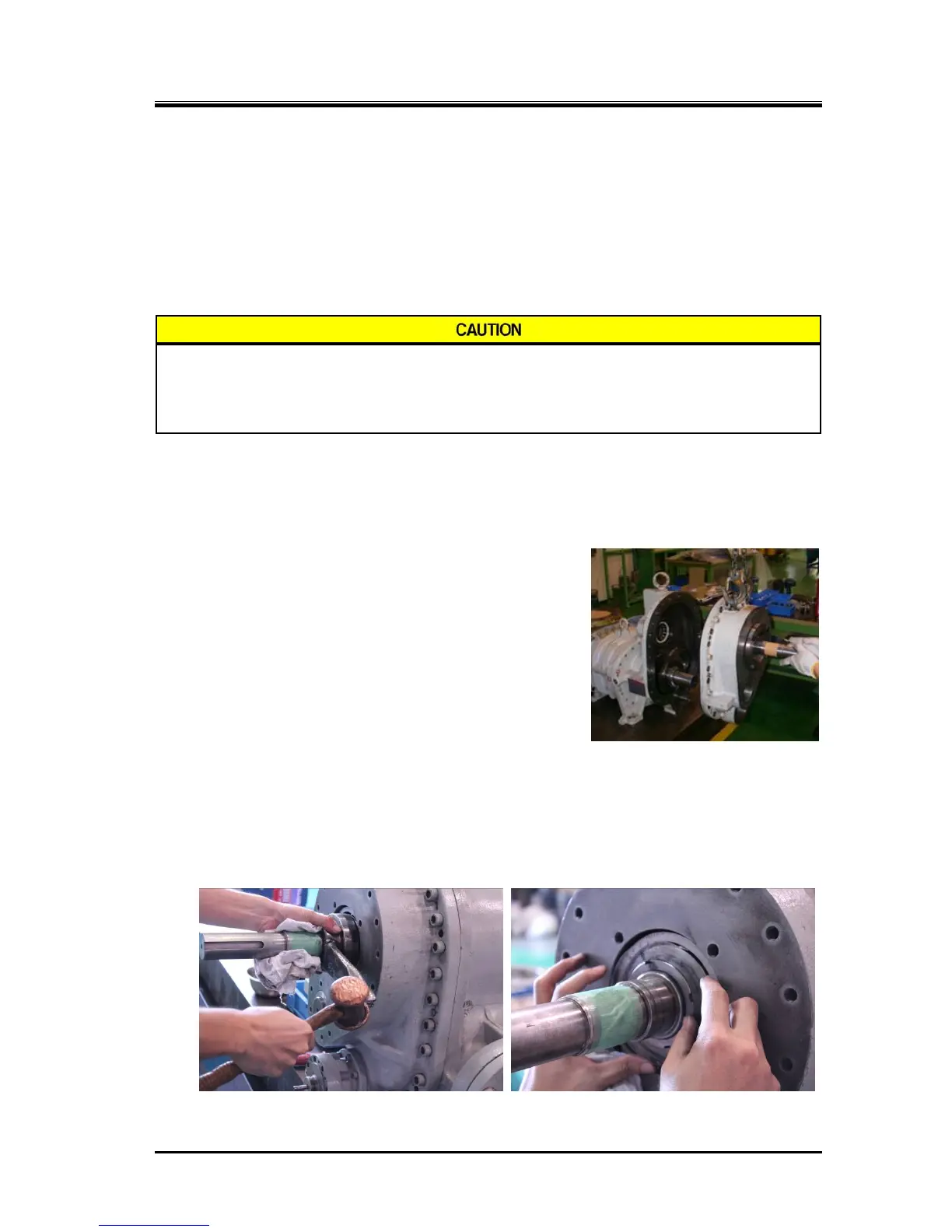

Install the speed increaser gear casing assembly to the low stage bearing head. For the sake of

safety, it is strongly recommended to perform this operation by suspending the speed increaser

gear casing assembly with a proper means like a chain block.

By holding the end of the spindle protruding from the speed increaser gear casing assembly, move

the assembly until the roller bearing outer race on the bearing

head engages with the roller bearing inner race on the spindle

and then press on the assembly in the axial direction (right

picture).

Do this operation while turning the spindle in both directions

by holding its end a little to make the speed increaser drive

and driven gears engage with each other.

d)

When the flanges of both blocks come into contact, align

them and temporarily tighten two hexagon socket head cap

screws [18-1] in a left-right symmetry way. Then, drive

alignment pins [19-1] into the low-stage bearing head.

e) Fasten the hexagon socket head cap screws [18-1] in turn and evenly to the specified torque.

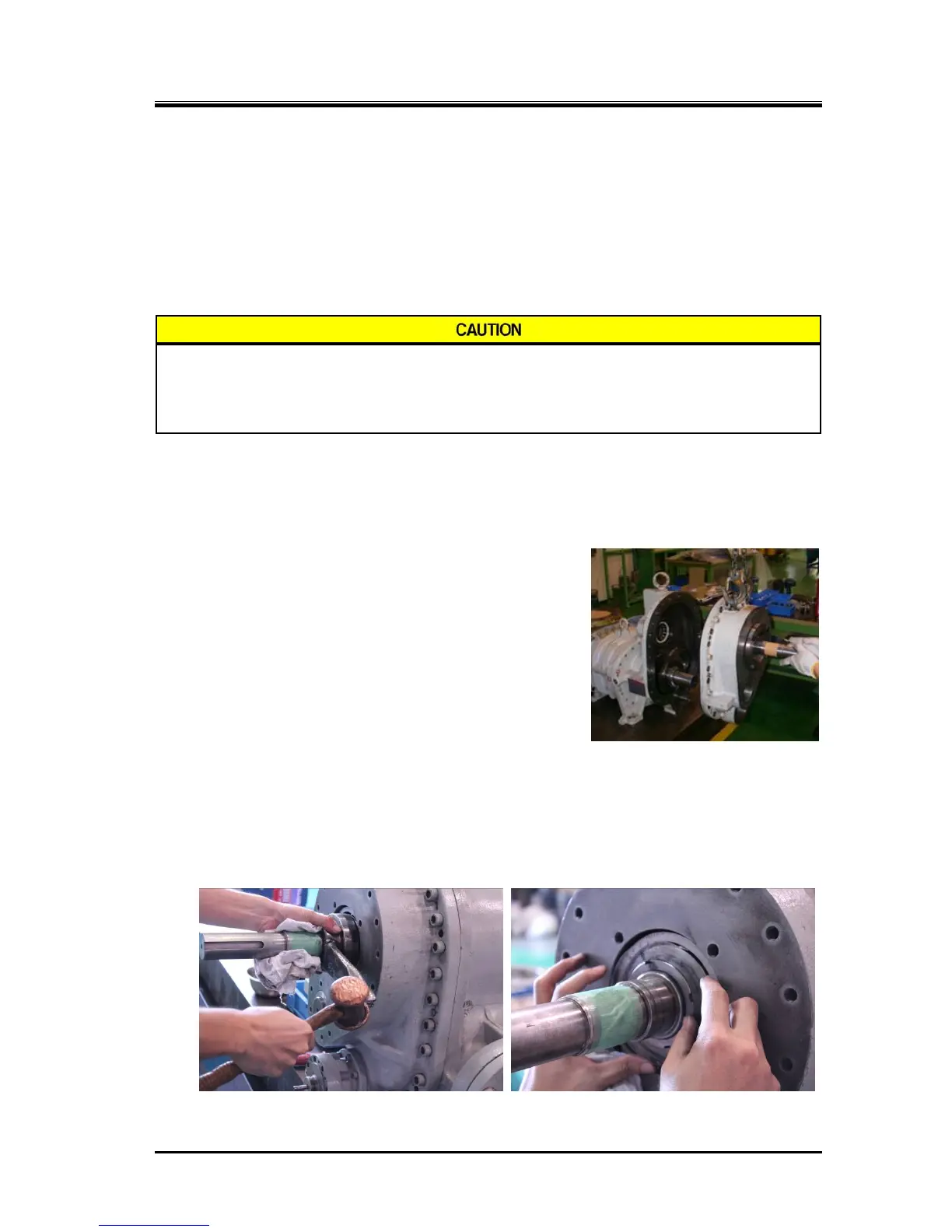

f) Remove the temporary thrust bearing holding jig to fix the thrust bearing inner race onto the speed

increaser gear spindle, insert the lock washer [194], torsional slip washer [237-1C] and the lock nut

[193]. Then, tighten the lock nut to the specified torque or within the specified range of the tightening

angle (following picture to the right) by using the lock nut wrench.

Also tightening the lock nut in this step should change the position of applying the lock nut wrench to

avoid uneven tightening (refer to Section 5.5.6 b) [POINT]).

Loading...

Loading...