2202L5JE-DA-C5-N_2015.05.

5 Maintenance and Inspection

Compound 2-stage Screw Compressor 5.4 Disassembly and Inspection

1612LSC Speed Increaser Type

5-27

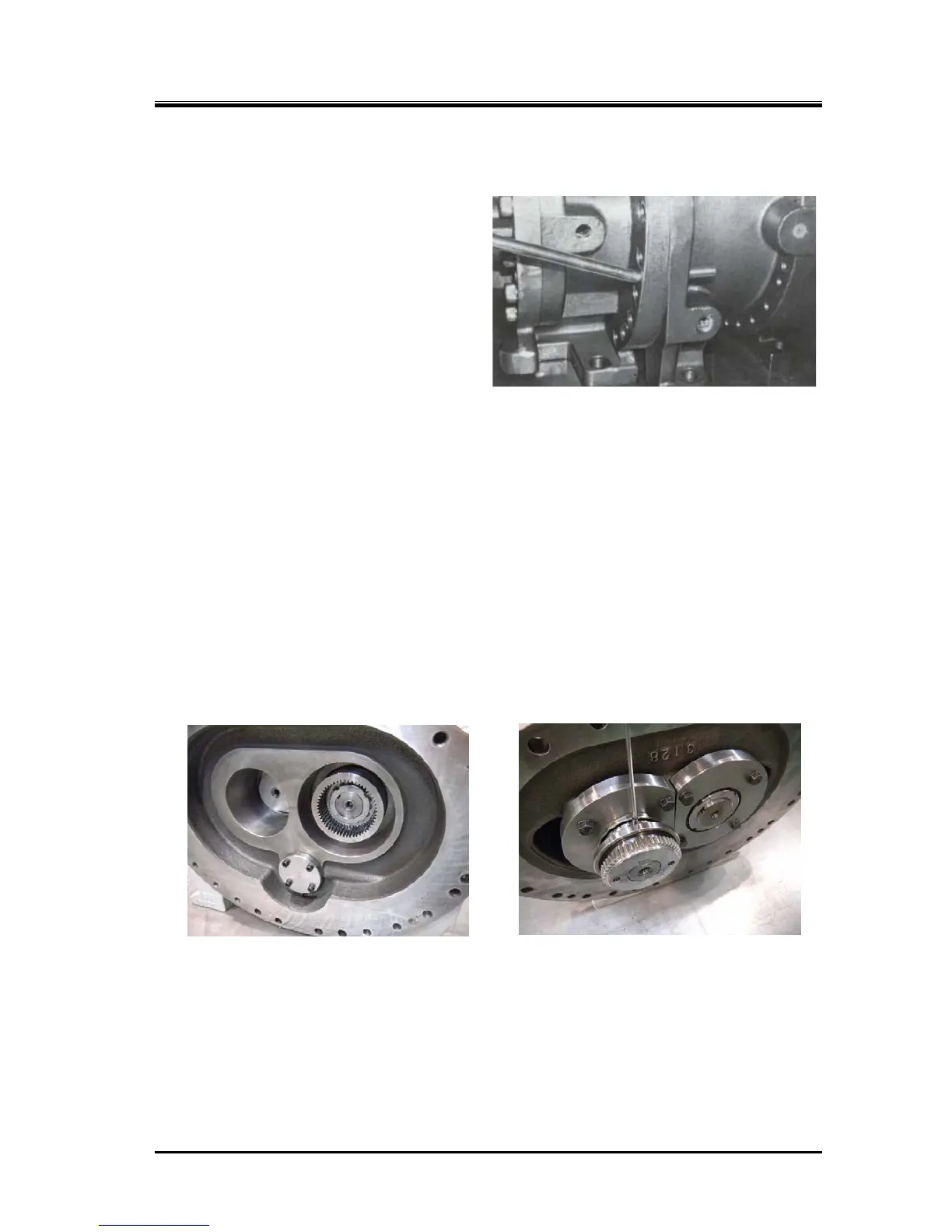

5.4.7 Separating High-stage and Low-stage

Separate the high-stage and low-stage when

inspect the high-stage thrust bearing block or pull

out each stage’s rotor is required.

Structurally, it does not matter even if separated

at the first step of disassembly.

Separating High-stage and Low-stage

5.4.7.1 Disassembly

a) As explained in Section 5.3.5 of this chapter, put the compressor on a special table and remove the

bolts from the lower side. Then, remove the remaining hexagon socket head cap screws [18-2].

At this moment, the high-stage of the compressor is spaced apart the work bench. Brace the

high-stage with a rectangular piece of wood or the like to prevent it from falling when disassembled.

b) Drive alignment pins [19-2] into suction cover [5-1].

c) Since the bearing head [11-2] and suction cover are stuck together with the gasket [17], screw the

previously removed bolts [18-2] into two jacking threaded holes on the bearing head to push out the

suction cover evenly.

Do not insert a screwdriver or chisel into the gap.

d) On the M rotor axis there are power transmission gear couplings [151 to 161].

Move the casing in parallel with the axis to separate the driving side and the driven side in the axial

direction.

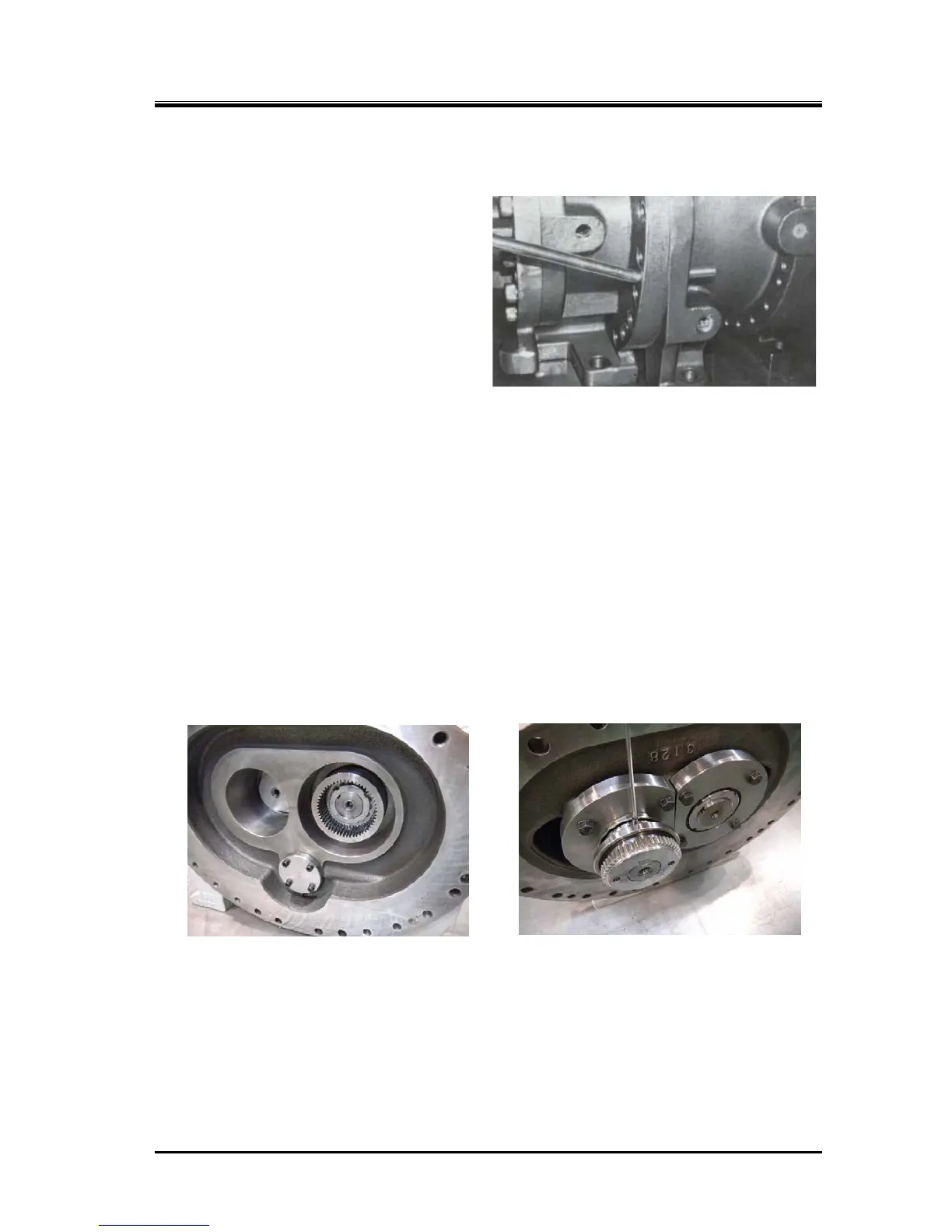

Low-stage After Separation Removing Driven Hub

* Above pictures are gear coupling before the design modification of February, 2011.

Loading...

Loading...