2202L5JE-DA-C5-N_2015.05.

2 Compressor Specifications and Structure

Compound 2-stage Screw Compressor 2.5 Mechanisms

1612LSC Speed Increaser Type

2-9

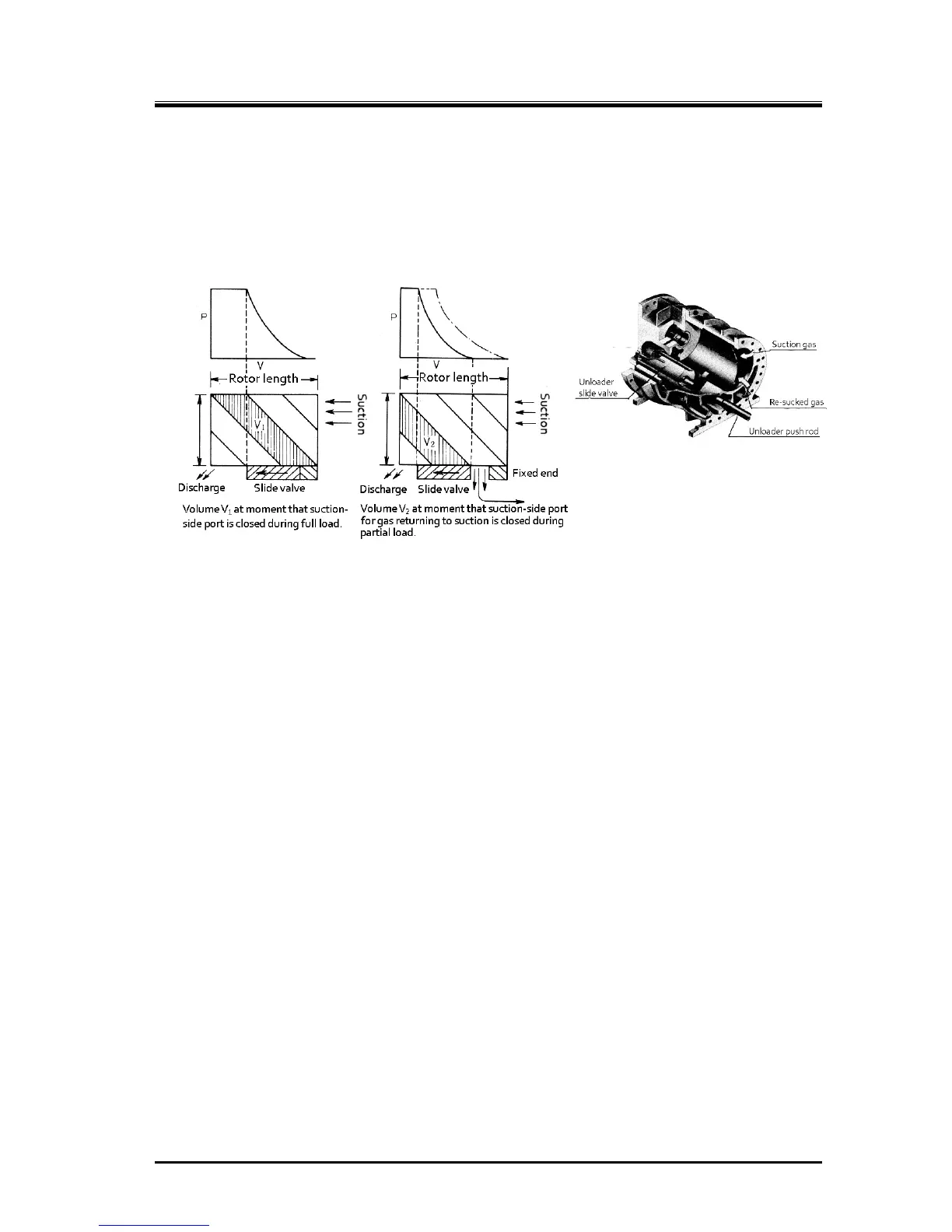

2.5.6 Capacity Control Mechanism

The capacity control structure involves the moving of a slide valve, bypassing suction gas just before

compression on the suction side, which shortens the portion of the rotor used for compression. The

slide valve is at the bottom of the casing where the rotors mesh together, and is constructed to move

parallel to the rotor’s axis. This movement is changed by a cam mechanism into rotation movement,

and as the position (capacity control ratio) is indicated externally, the electrical resistance value

changes to provide feedback to the automatic control circuit.

Figure 2-9 Capacity Control Mechanism

The 1612LSC speed increaser type has capacity control on the low-stage block only.

2.5.7 Bearings and Balance Piston

For the load created on the rotor perpendicular to the axle, a white metal-lined sleeve-type bearing is

used. The bearing uses surface fitted ball bearings with angular contact for loads along the axis

direction.

In particular, axial load for the M rotor, which has one type of helical gear, is comparatively larger than

that of the F rotor because of the thrust load from discharge pressure. This load for the M rotor is

reduced by the use of a thrust bearing, along with a balance piston providing opposing hydraulic

pressure.

2.5.8 Shaft Seal

To prevent refrigerant gas and oil leakage, a reliable mechanical seal assembly is used for the shaft

seal of the speed increaser gear spindle.

Mechanical seal assembly is mainly composed of "rotating ring" installed on the rotor shaft and

"stationary ring" installed in the seal cover. Rotating ring rotates with the shaft, and slides each other

with the stationary ring while maintaining a micron class gap. The sliding each other place is called as

the sliding surface.

As an example, for the BBSE (Balanced Bellows Single Seal)-type, which is a standard seal currently in

use, the fixed ring (mating ring) is cast iron, and the rotating ring is carbon, with an O-ring for the

packing.

Figure 2-10 Slide Valve in the

Rotor Casing

Loading...

Loading...