Oki Data CONFIDENTIAL

44043511TH Rev.2

178 /

5.4 Paper Thickness Detection/Sensitivity Correction

A maintenance utility is supported as an object for field maintenance. (Refer to the maintenance

utility for the usage)

Overview

The sensitivity of the micro-displacement sensor used as the media thickness detector are not

uniform in detection sensitivity. To learn the sensitivity of that unit’s sensor beforehand, there is a

need to pass a media source with a priorly known thickness through the detector. The sensitivity

shall then be detected based on the output value of the sensor.

Adjustments are necessary when replacing the Paper Thickness Sensor, Resist Roller and PU

PCB.

Prepare four media sources with a thickness already measured with a micrometer (MDQ-30M,

MDQ-30). Then pass those sheets through the MP Tray. The media thickness sensitivity

correction value is automatically set with the 3 sheets. Then the media thickness detection

value is tested with the 4th sheet.

Media Used : Transparency Sheet (42404301)

Paper Thickness Detection Error : ±10µm or less

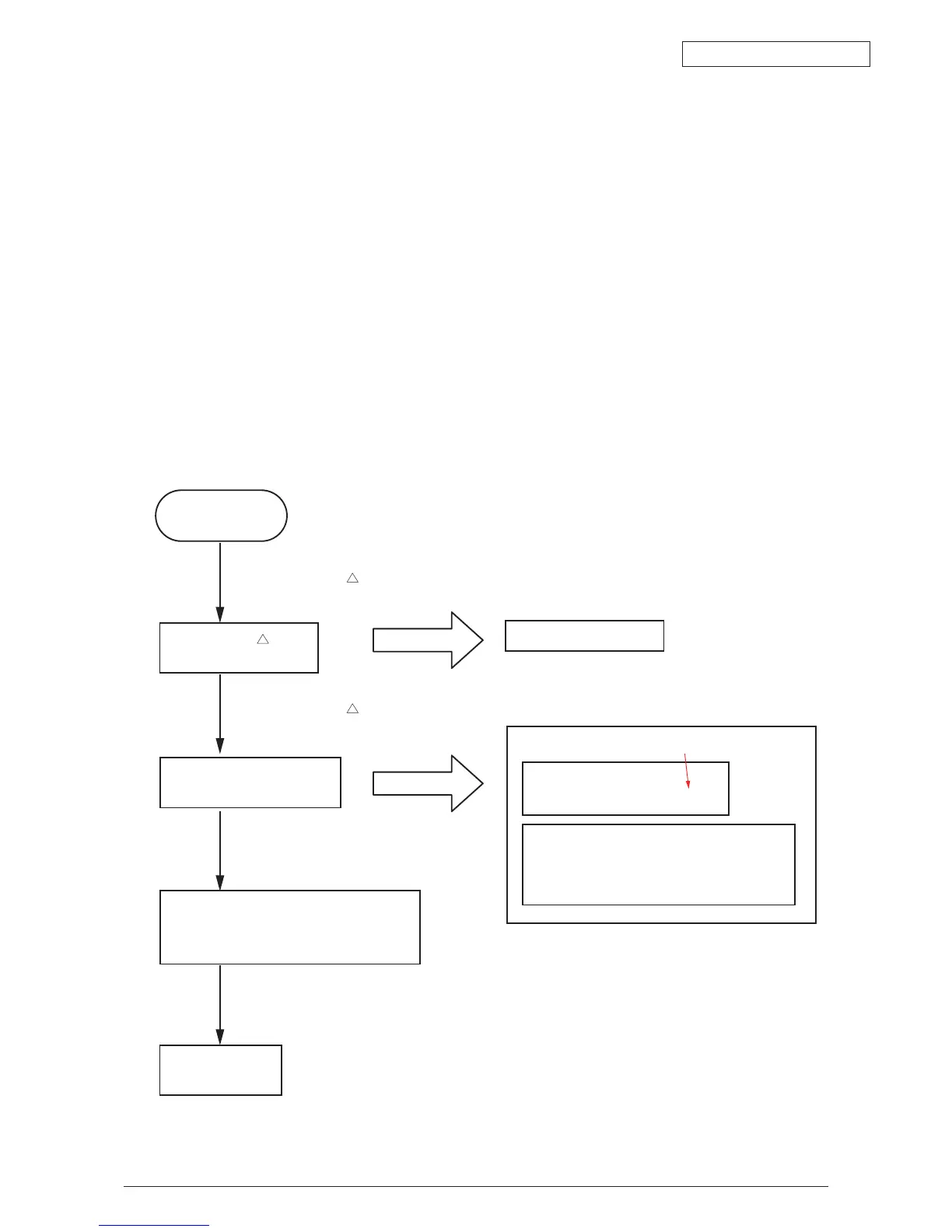

Press Triangle () Button

until Panel Display Is:

Diagnostics mode

Press the triangle ()

a few times.

Panel Display

Press Enter.

Press the triangle () a few times.

Press Enter.

Use Precision Screwdriver (Flathead) to

Turn Adjustment Screw to Adjust Value to

Range FAh to 15Eh (Target 12C (Hex)).

Turn Off Printer.

Check Panel Display Is:

Display

Display

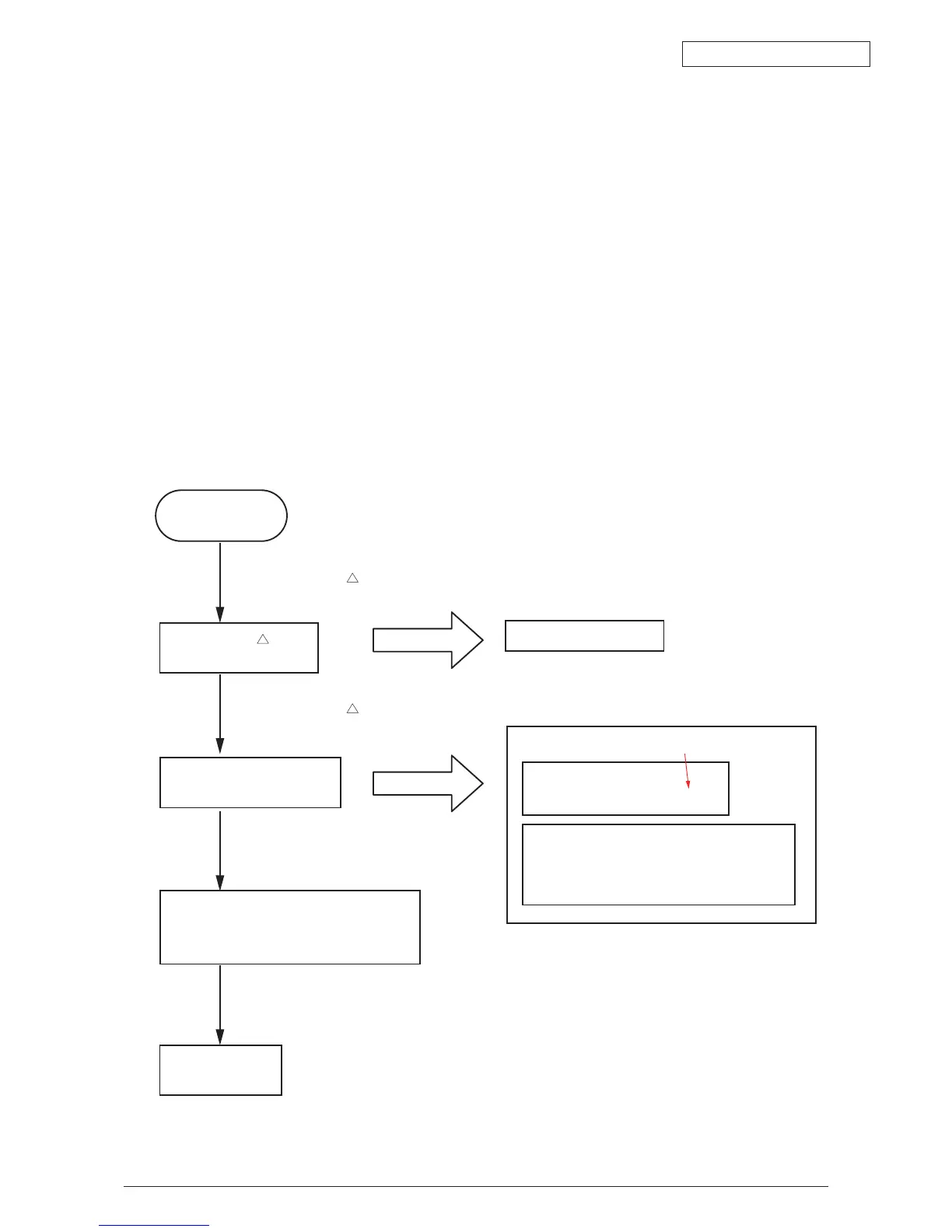

4=

***

Weight sensor output displayed

at three asterisks [

***

].

Value changed by turning adjustment screw.

REG L/R xxx WEIGHT

1=

***

2=

***

3=

***

4=

***

SWITCH SCAN

Zero Point Value

Loading...

Loading...