30

Setting Output Specifications Section 3-5

3-5 Setting Output Specifications

3-5-1 Control Period

• Set the output period (control period). Though a shorter period provides

better control performance, we recommend setting the control period to

20 seconds or more taking the life expectancy in the case of relay output

into consideration. If necessary, readjust the control period by trial opera-

tion, for example, when the control period parameters are set to their

defaults.

• Set the control period in the “control period (OUT1)” and “control period

(OUT2)” parameters (initial setting level). Default is “20 seconds”.

• The “control period (OUT2)” parameter can be used only in heating/cool-

ing control.

• Whenever control output 1 is the current output, “control period (OUT1)”

cannot be used.

3-5-2 Direct/Reverse Operation

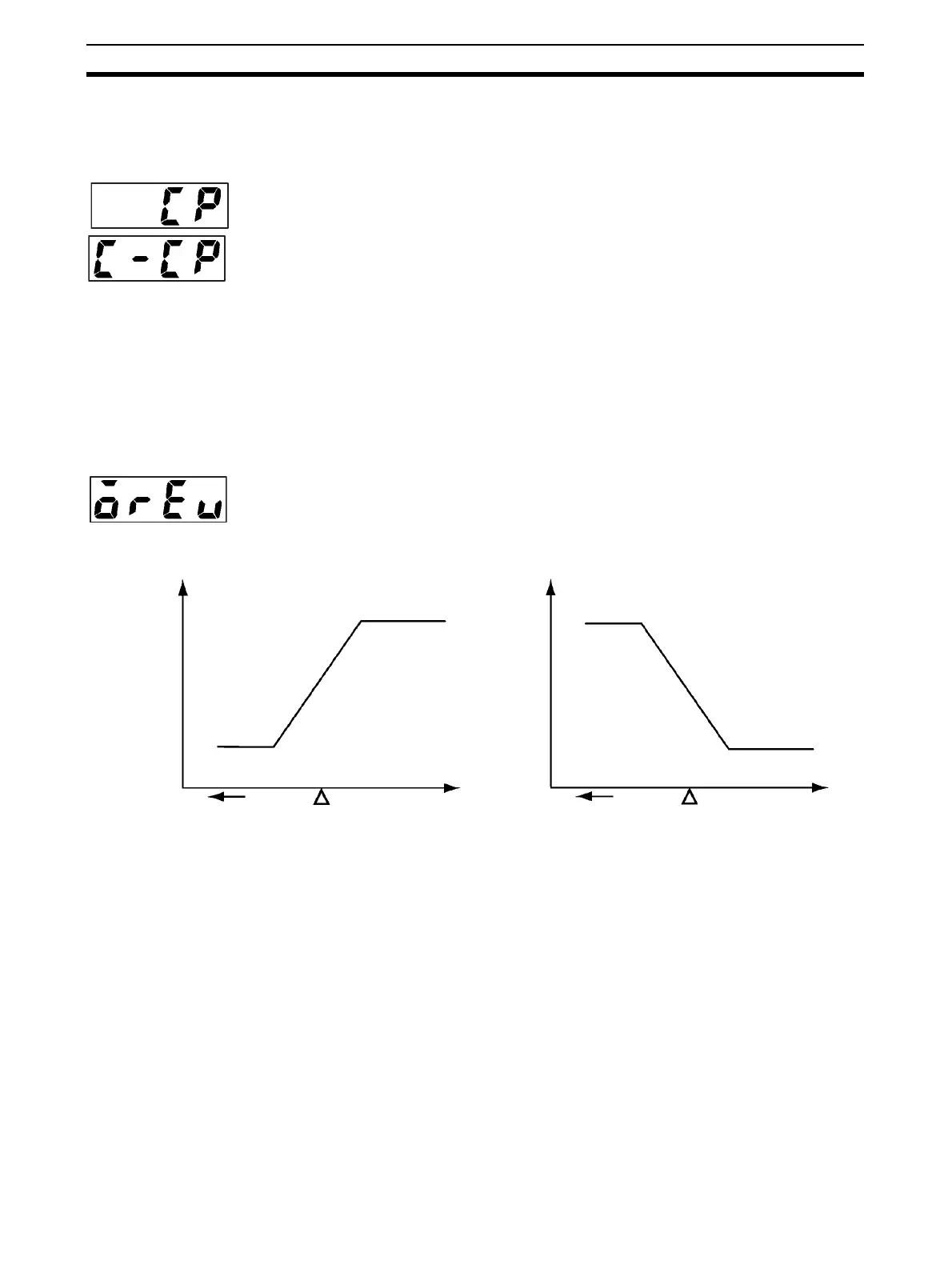

• “Direct operation” refers to control where the manipulated variable is

increased according to the increase in the process value. Alternatively,

“Reverse operation” refers to control where the manipulated variable is

decreased according to the increase in the process value.

For example, when the process value (PV) (temperature) is lower than the set

point (SP) (temperature) in a heating control system, the manipulated variable

increases by the difference between the PV and SP values.

Accordingly, this becomes “reverse operation” in a heating control system, or

alternatively, “direct operation” in a cooling control system.

• Direct/reverse operation is set in the “direct/reverse operation” parameter

(initial setting level). The “direct/reverse operation” parameter default is

“reverse operation”.

Control

period

(OUT1)

Control

period

(OUT2)

High temperature

Manipulated variable

Direct operation

Low temperature

Set value

High temperature

Manipulated variable

Reverse operation

Low temperature

Set value

100%

0%

100%

0%

Loading...

Loading...