6.6 Program Example

E5CK

6–19

JExamples of use

Ă• Set the unit No. to 00".

Ă• In the following examples, data is shown in individual blocks to make the examples

easier to understand. However, when actually creating programs, do not leave spaces

between frame items. Also, response are displayed without spaces between frame

items.

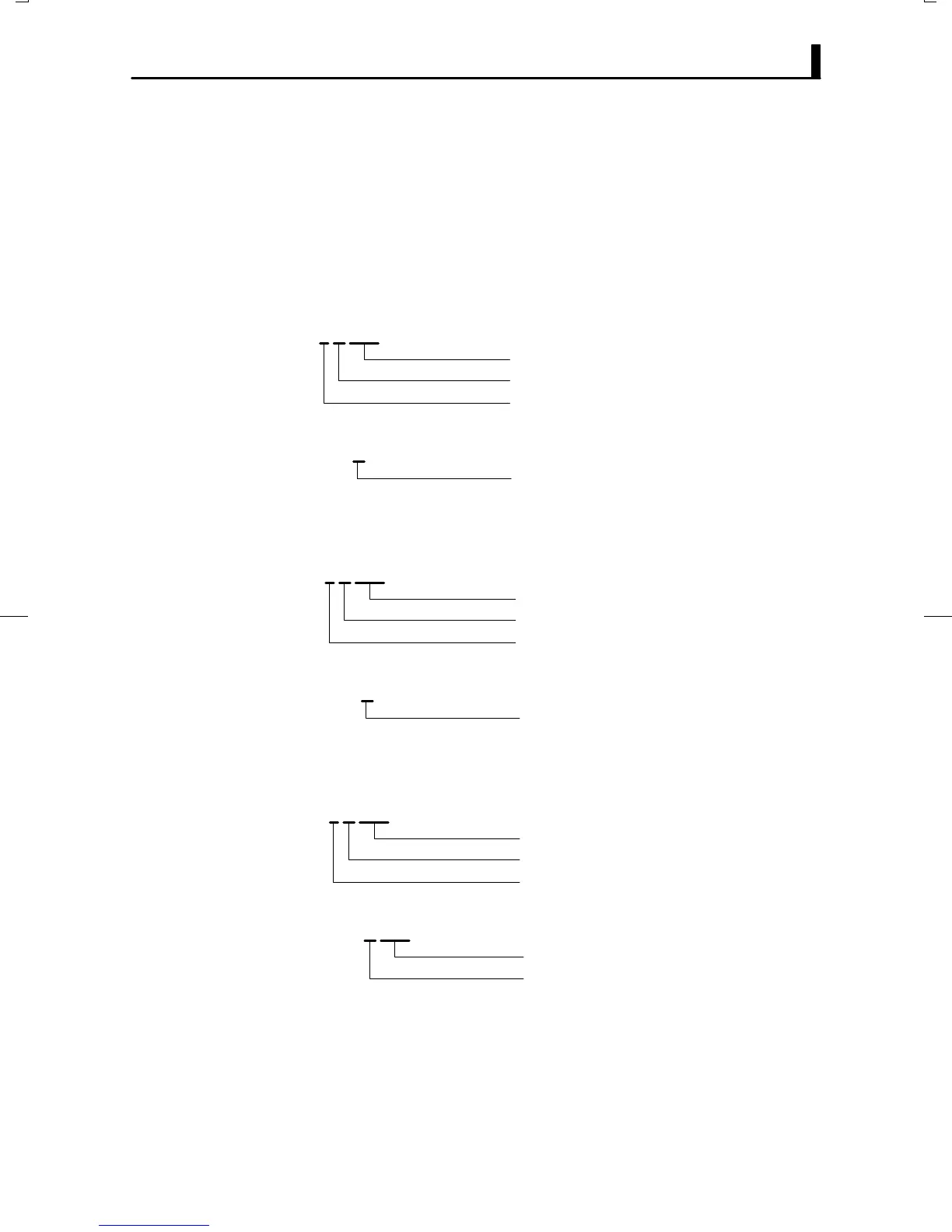

F Set the set point to “300.0”

Ă• Input data

@ 00 5 05 3000

300.0

Set point

Write parameter

Ă• Response

@ 00 5 05 00 3000 (FCS) *

Normal end

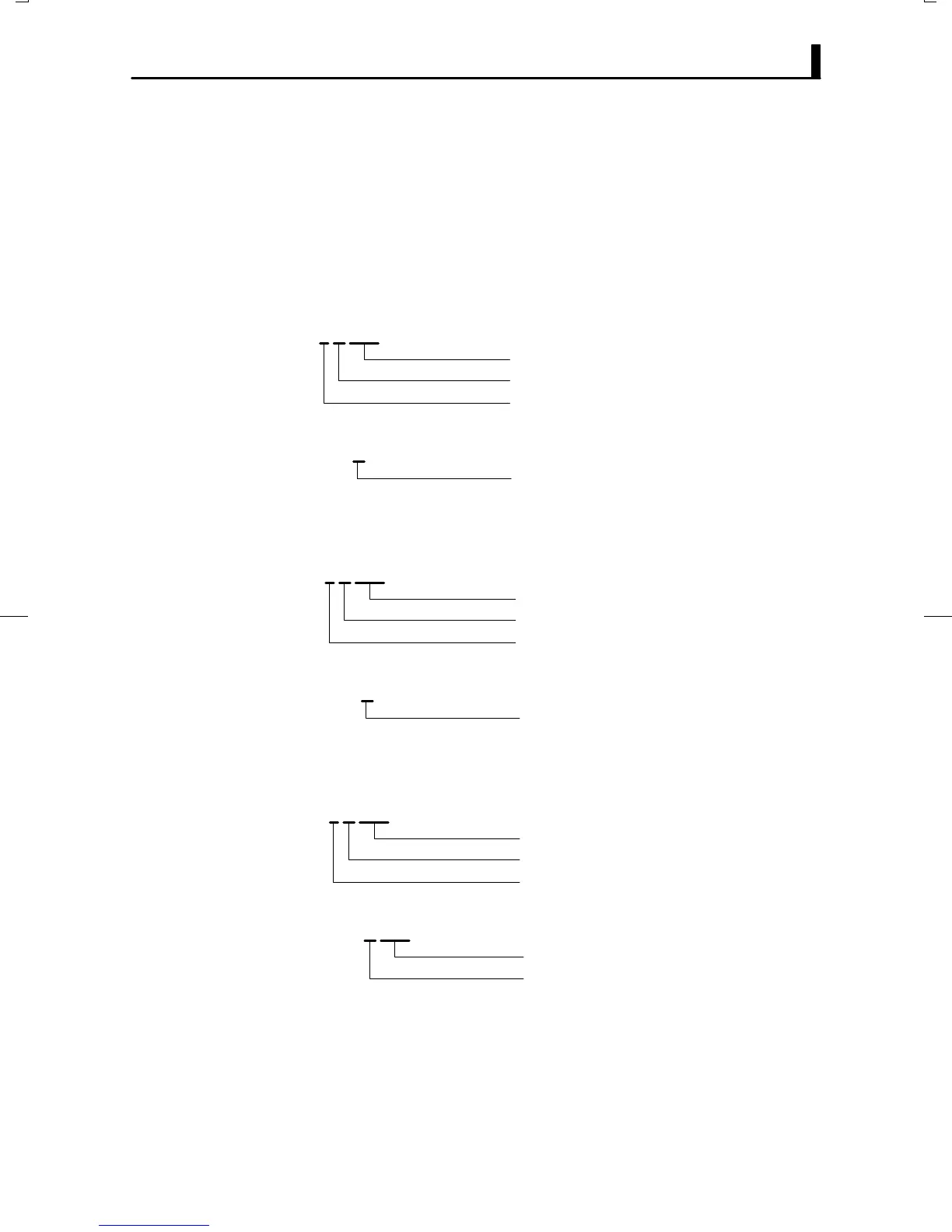

F Start running

Ă• Input data

@ 00 3 00 0000

Run

Run/Reset

Special command

Ă• Response

@ 00 3 00 00 0000 (FCS) *

Normal end

F Monitor process value

Ă• Input data

@ 00 1 00 0000

Dummy data

Monitor process value

Read parameter

Ă• Response

@ 00 1 00 00 2000 (FCS) *

Process value = 2000

Normal end

Loading...

Loading...