CHAPTER 4 APPLIED OPERATION

E5CK

4–10

4.4 Program Operation

Ă• Steps in currently executing programs can be forcibly stopped (Hold)

and advanced (Advance).

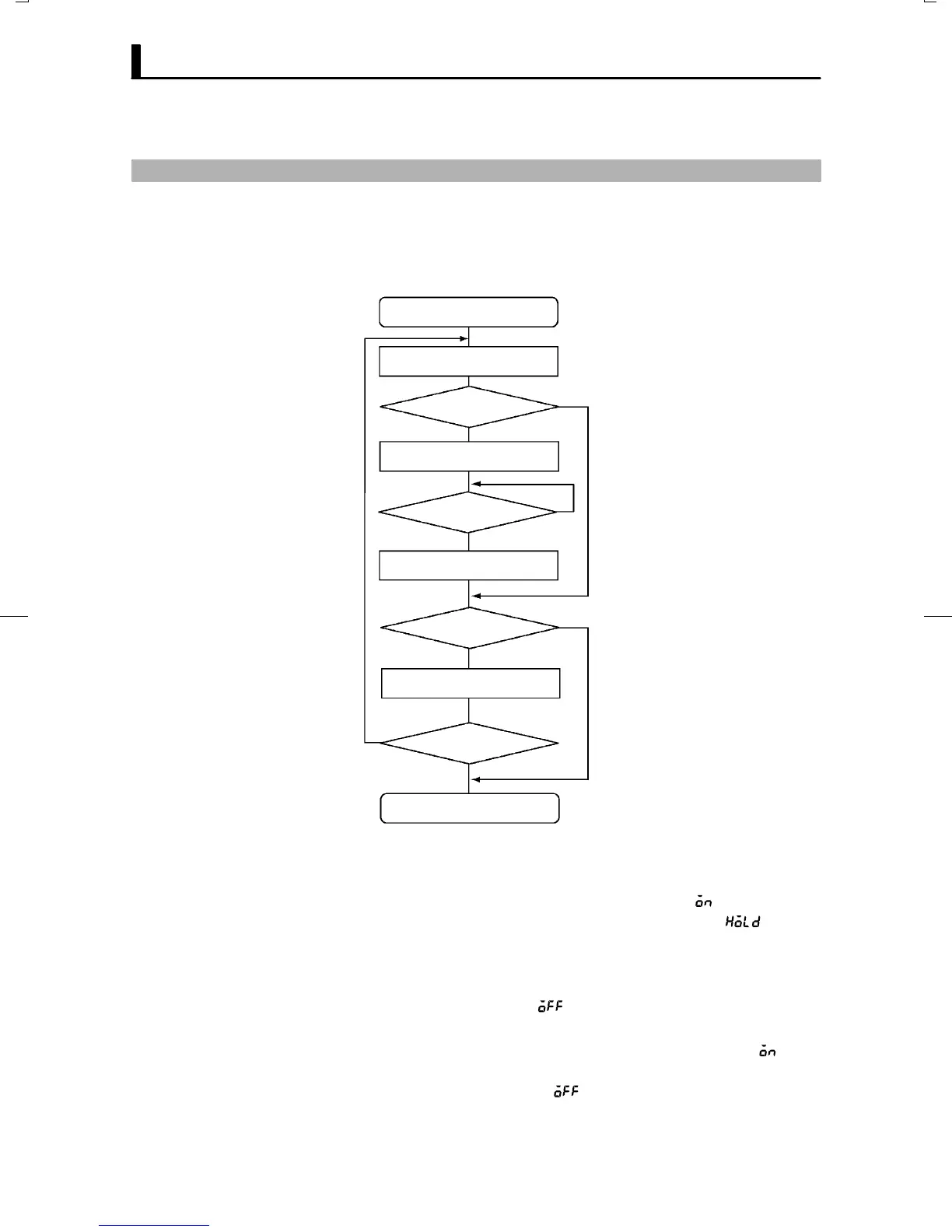

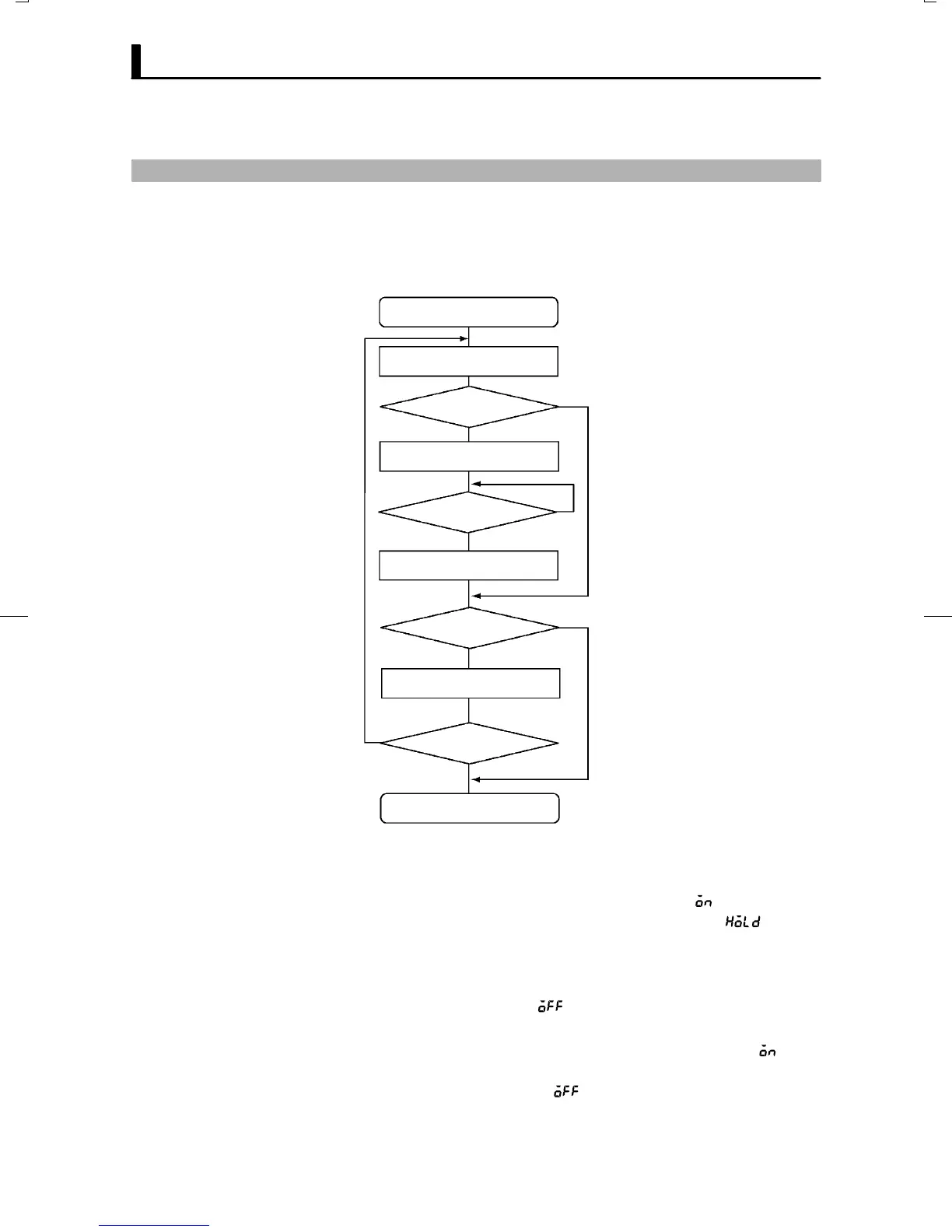

Ă• Hold and Advance operation is according to the following procedure:

Run in level 0 mode

Check step No.

Hold?

Hold = ON

Continue

End of hold?

End

Hold = OFF

Advance

Advance = ON

Continue

End of advance

End

End: To program operation

Y

Y

N

N

Ă• Execute hold/advance operation while making sure the step No. in the

step No. monitor" parameter (level 0 mode).

Ă• When the hold" parameter (level 0 mode) is set to : ON", step time

counting is paused (held), and the HOLD" LED lights. [

] and the

SP appear alternately on the No.2 display when in the PV/Present SP"

parameter.

Ă• Hold is canceled time counting is restarted by one of the following condiĆ

tions: hold" parameter = : OFF", Run, Reset, End operation usĆ

ing advance instruction

Ă• Each time that advance" parameter (level 0 mode) is set to : ON",

the program advances one step. With each step advance, the Advance"

parameter setting returns to : OFF".

Ă• If the advance function is executed with the program in a hold state, the

hold state is continued in the next step.

JHold/advance

Loading...

Loading...