Chapter 8: Maintenance

l

Gloves.

l

Disposable lint-free wipes.

l

Detergent-based cleaning liquid.

l

Grease gun with flexible nozzle for a grease (Zerk) nipple.

l

Seal pick to remove O-ring seal.

l

NLGI-2 bearing and O-ring grease.

l

Four replacement O-rings

NOTE: Even though a Zerk fitting is provided on the caster axle, do not lub-

ricate the caster axle.

Use the following ESD caster lubrication procedure:

1.

Press an E-Stop button and power off the LD-250 to put it into a safe working state. and

safely lift up the LD-250 so that you can access the casters.

2.

Remove the front lower and rear right and left skins. See: Removing and Installing Skins

on page 178.

3. Remove the caster wheel. See the procedure to remove a caster wheel in: Replacing a

Caster Wheel on page 171.

4.

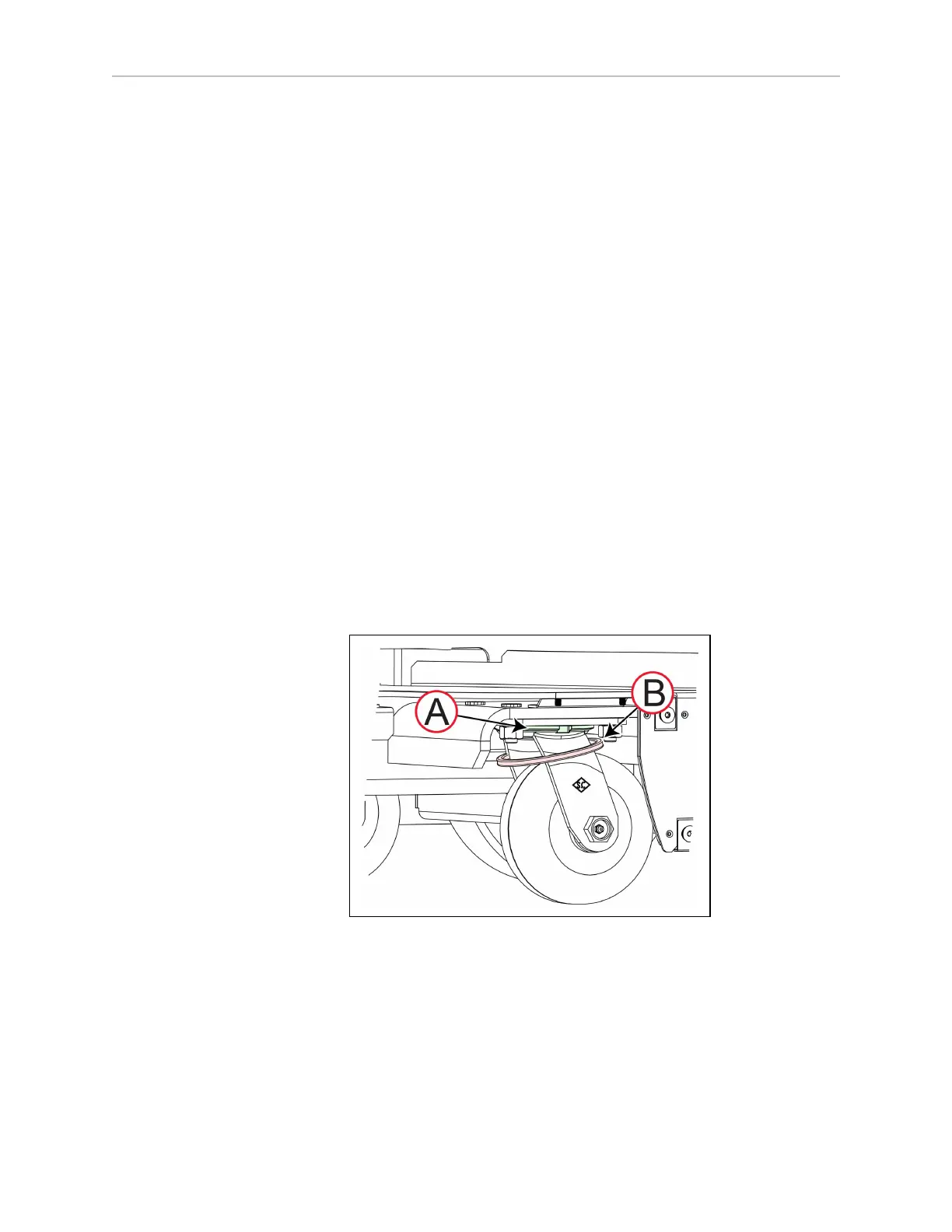

The caster yoke's bearing race (A) is covered by an O-ring (B). Remove the O-ring by

pulling it down with a seal pick and dispose of it.

Figure 8-5 Caster Yoke Bearing and O-Ring

5.

Use disposable wipes to remove old grease and dirt from the yoke bearing [(A) in Figure

8-5].

6.

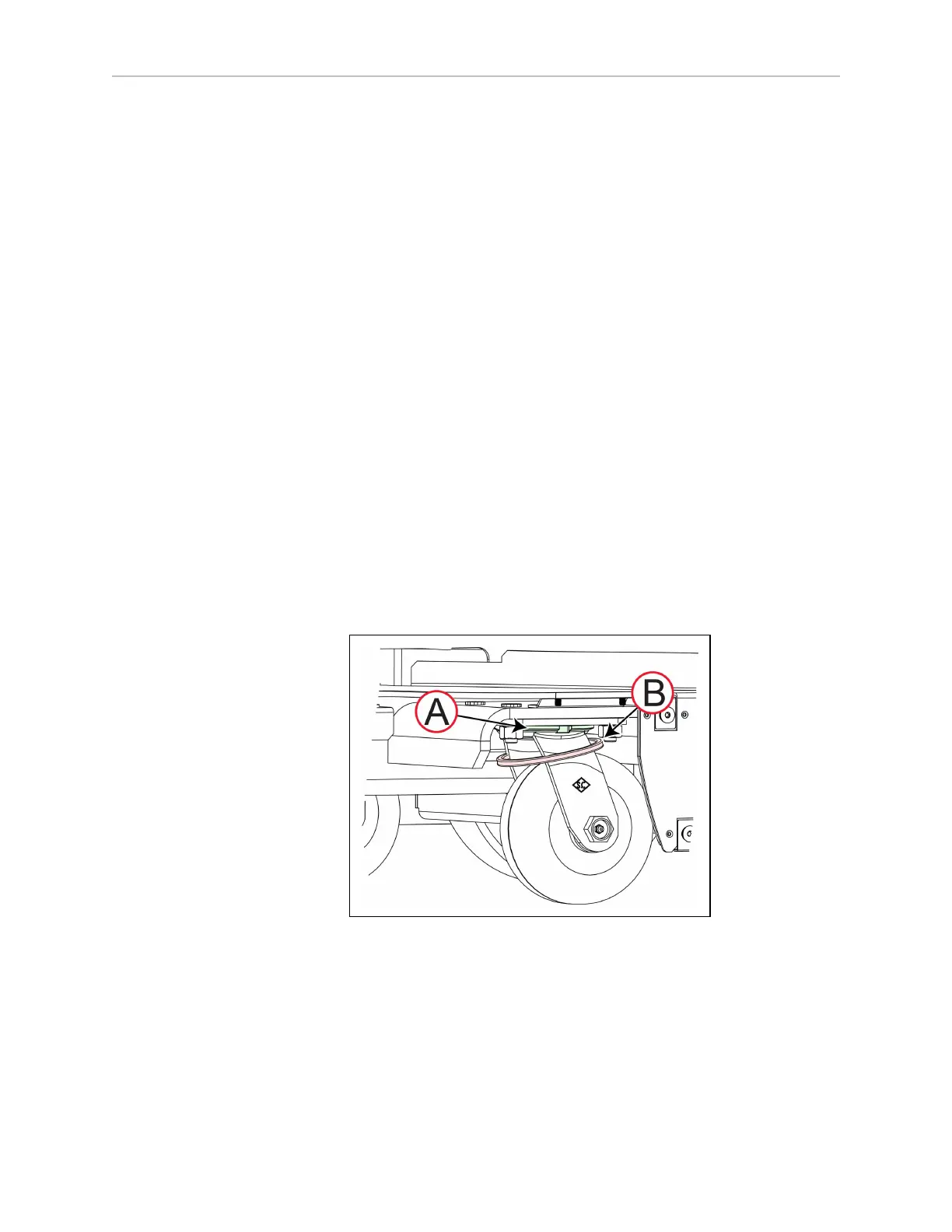

Use the grease gun to apply only two pumps of grease through the Zerk fitting in the

yoke bearing [(A) in Figure 8-6]. Avoid applying grease to the wheel.

20472-000 Rev B LD-250 Platform User's Guide 155

Loading...

Loading...