Adjustment

14 - 23

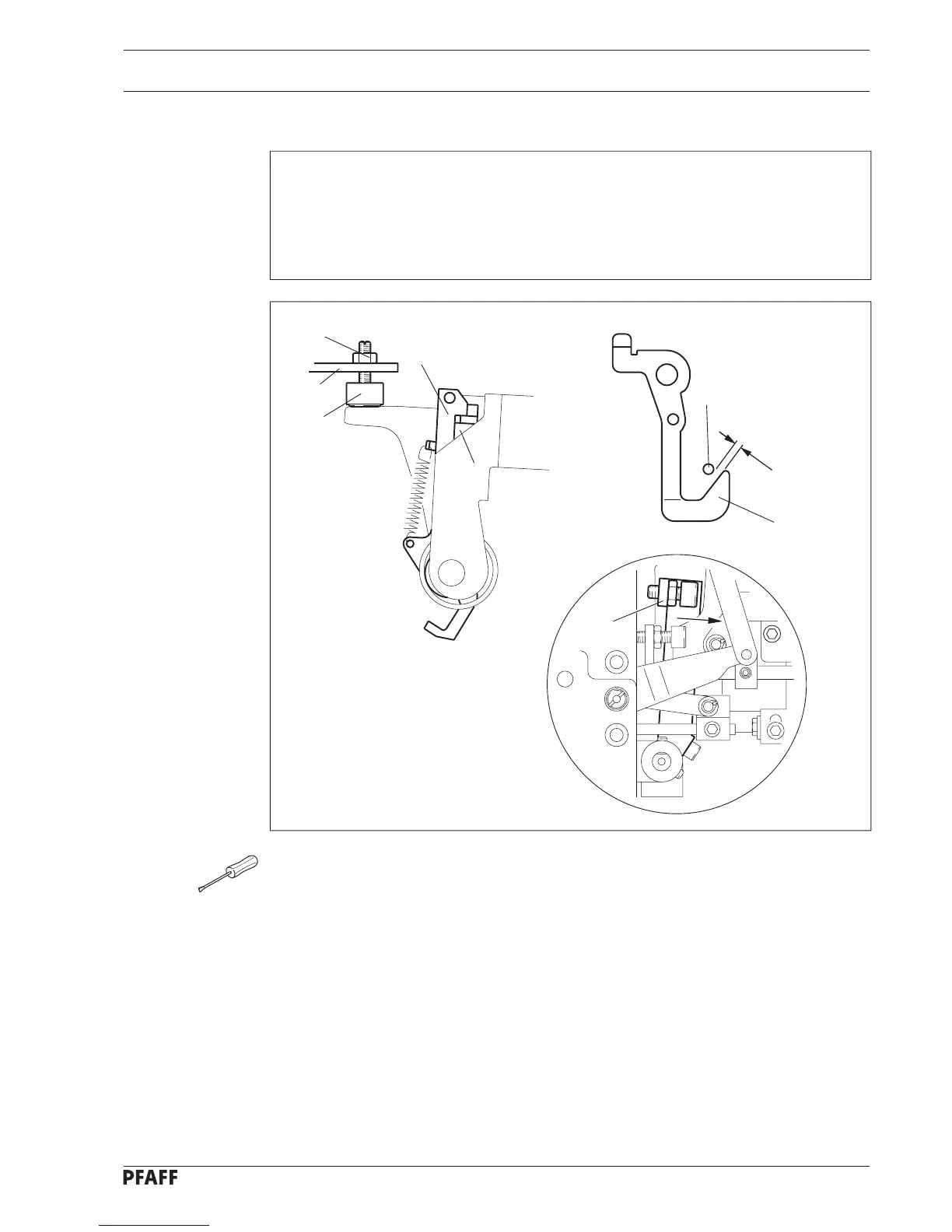

14.12.02 Upper knife-arm-stop

Requirement

1. Taking care to ensure that the carrier plate 1 is pushed as far forward as possible in its

elongated holes there must be a clearance of 0.2 mm to 0.3 mm between finger 2 of

the needle thread monitor and pin 3 of the knife latch.

2. The knife latch 4 must fall into the actuator finger 5 when it is just below its TDC.

1

5

7

6

4

0.2 - 0.3 mm

3

2

8

Fig. 14 - 22

● Loosen nut 6 and turn the stop motion buffer 7 in accordance with requirement 1.

● Tighten nut 6.

● Engage the stop motion device.

● Turn the drive pulley in its direction of rotation until the actuator projection 5 is in its BDC.

● Hold the thread monitor finger forwards.

● Manually switch on the knife by pulling lever 8.

● The knife latch 4 positions itself in front of the actuator projection 5.

● Turn the drive pulley in its direction of rotation until the actuator projection 5 is just below

its TDC.

● The knife latch 4 must then fall into the actuator projection 5.

● If this does not happen readjust the stop motion buffer 7 in accordance with require-

ment 2.

● Turn the drive pulley in its direction of rotation until the knife latch 4 is in its basic position.

● Disengage the stop motion device.

Loading...

Loading...